Loading ...

Loading ...

Loading ...

Gas Conversion and Specifications

30

NOTE:

• These conversions should only be carried out by qualified

persons. All connections must be checked for leaks before

re-commissioning the appliance.

• Adjustment of components that have adjustments /settings

sealed (e.g. paint sealed) can only be adjusted in

accordance with the following instructions and shall be

re-sealed before re-commissioning this appliance.

• For all relevant gas specifications refer to the table at the

end of this section.

1. Remove the lower service panel to allow access to the gas

control valve.

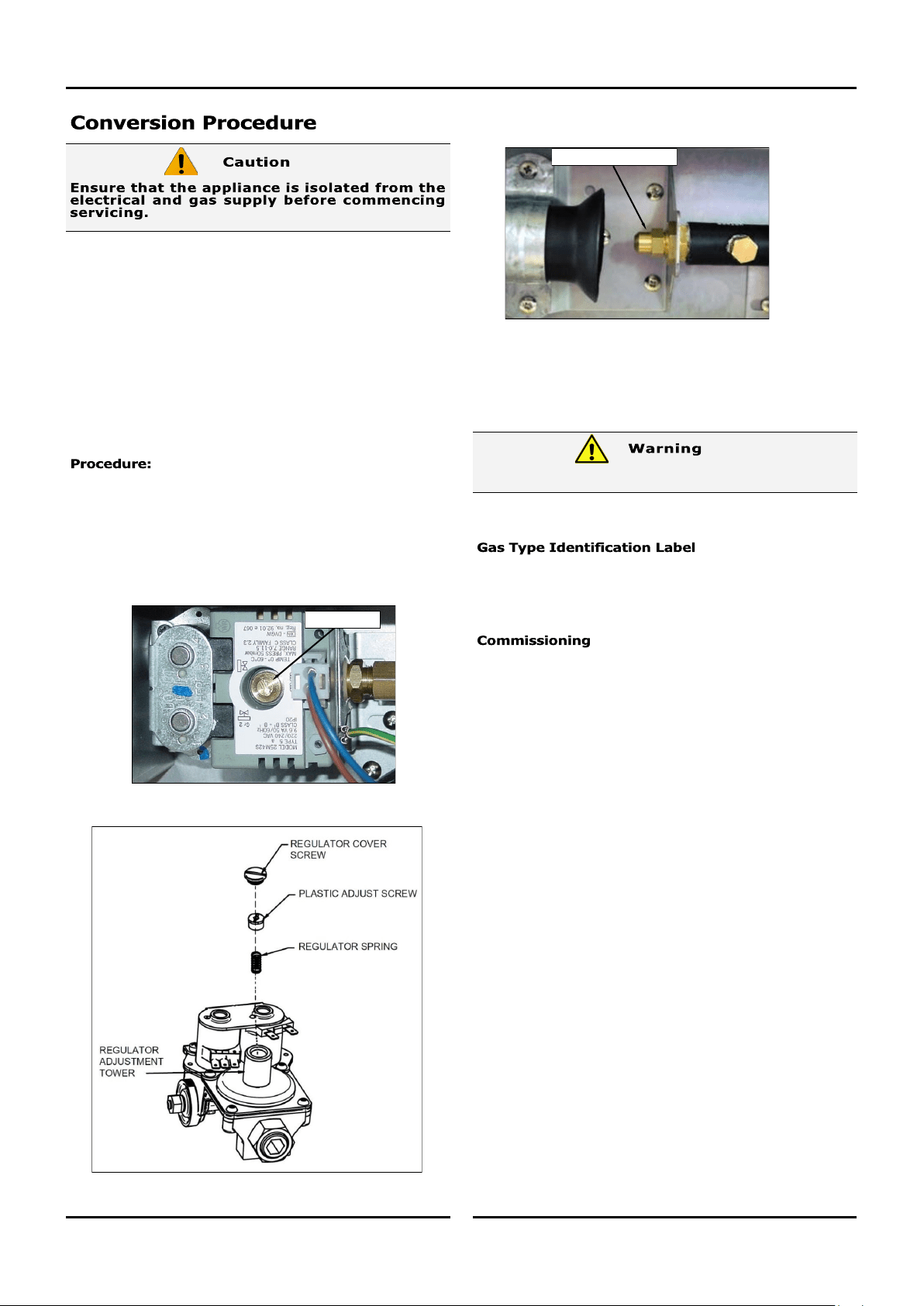

2. Unscrew and remove the regulator cover screw from the

regulator incorporated in the gas control.

3. Remove the plastic adjusting screw and regulator spring from

the gas control valve. Replace with correct spring supplied with

the conversion kit.

4. Unscrew and remove the main burner injector and replace with

appropriate item.

5. Connect gas and electrical supplies.

6. Operate oven and adjust the plastic adjust screw on the

regulator to achieve correct pressure at pressure test point

(front RH corner).

7. Refit the regulator cover screw to the gas valve.

8. Conduct full leak test of the converted oven prior to placing it

into operation.

9. Refit the service panels.

On completion of the gas conversion, replace the gas type

identification label with the appropriate label, located at:-

- The rear of the appliance, above the gas connection point.

Before leaving the converted installation;

1. Check all gas connections for leakages using soapy water or

other gas detecting equipment.

2. Check the following functions in accordance with the operating

instructions specified in the ‘Operation’ section of this manual.

• Ensure that all the oven controls operate correctly.

• Ensure that the operating pressure remains correct.

3. Ensure any adjustments done to components that have the

adjustments / settings sealed (e.g. paint sealed), are re-sealed.

NOTE: If for some reason it is not possible to get the

appliance to operate correctly, shut off the gas

supply and contact the supplier of this appliance.

Do not use a naked flame to check for gas leakages.

Main Burner Injector

Cover Screw

Loading ...

Loading ...

Loading ...