Loading ...

Loading ...

Loading ...

English

— 12 —

4. About the thermal protection

The thermal protection operates to stop the motor when a

problem such as a motor overload, etc. occurs.

If the motor stops during operating, reset by pushing the

Reset switch (Refer to Fig. 6).

If the motor does not start or if it stops immediately,

proceed as follows.

(1) Place the knob of the pressure switch in the “OFF”

positon and disconnect the plug from the receptacle

(Fig. 2).

(2) Check for the following possible causes fi rst: lack

of proper ventilation, or an outside-air or room

temperature that is too high.

(3) If the extension cord does not conform to the

specifi cations given on page 7 replace with an

extension cord such as that shown on page 7. If the

capacity of the power supply is insuffi cient, increase

the power supply capacity to remove the cause of a

fl ow of excessive current (over-current).

(4) Wait approximately 20 minutes.

(5) Start up. If the motor still stops during operation,

please contact the service center.

Protective breaker

Reset switch

Fig. 6

MAINTENANCE

WARNING: Disconnect the compressor from

the power source and remove the

compressed air from the air tank

before performing the maintenance

operations. Allow the compressor

to cool before performing the

maintenance operations.

1. Draining tank

Drain tank daily or after 4 hours of use. Open drain cock

and tilt compressor to empty accumulated water (Refer

to Fig. 5). Tank pressure should be below 10 psi when

draining the tank.

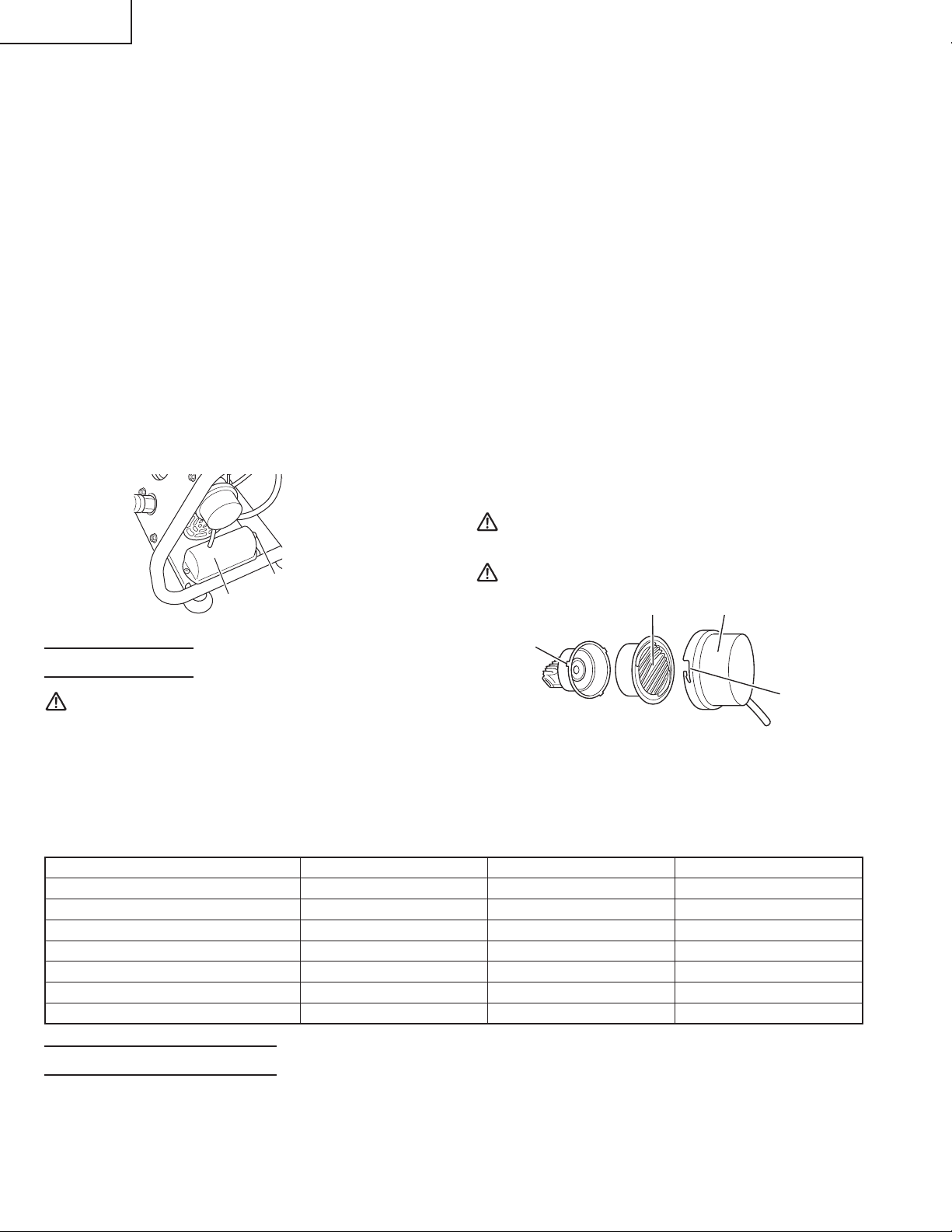

2. Cleaning the intake fi lter

Open the intake fi lter (Refer to Fig. 1) once a week and

clean the inside of the intake fi lter and the fi lter element

with compressed air (Fig. 7).

(1) Removal

Turn the intake fi lter counter-clockwise until it stops

and then remove the intake fi lter and fi lter element.

(2) Installation

After inserting the fi lter element, match the grooves of

the intake fi lter with the three protrusions on the main

unit so that the hose points downward. Then, turn the

intake fi lter clockwise until it stops. (Refer to Fig. 7)

Check to see if the intake fi lter is loose. If the fi lter is

loose, remove and reinstall the fi lter.

WARNING: Never clean fi lter element with a

fl ammable liquid or solvent.

CAUTION: Do not operate without the intake fi lter.

Intake fi lterFilter element

Grooves (× 3)

Protrusions (× 3)

Fig. 7

NOTE: Replace the fi lter element when it becomes dirty.

3. Maintenance chart:

MAINTENANCE CHART

PROCEDURE AFTER USE DAILY WEEKLY

Drain condensation in air tank × ×

Inspect guards/covers ×

Check for unusual noise/vibration ×

Check for air leaks ×

Clean exterior of compressor ×

Check safety valve ×

Clean intake fi lter/fi lter element ×

SERVICE AND REPAIRS

All quality compressors will eventually require servicing or

replacement of parts because of wear and tear from normal

use. To assure that only genuine replacement parts will

be used, all service and repairs must be performed by a

metabo HPT AUTHORIZED SERVICE CENTER, only.

NOTE: Specifi cations are subject to change without any

obligation on the part of the metabo HPT.

000BookEC28Mmetabo.indb12000BookEC28Mmetabo.indb12 2018/03/278:43:452018/03/278:43:45

Loading ...

Loading ...

Loading ...