Loading ...

Loading ...

Loading ...

Adjust skid shoes by loosening the four hex nuts

and carriage bolts and moving skid shoes to

desired position. Make certain the entire bottom

surface of skid shoe is against the ground to avoid

uneven wear on the skid shoes. Retighten nuts and

Carriage Bolts

Hex Nuts

Skid Shoe

Figure 21

bolts securely.

_, ARNING: Do not operate this snow

thrower on gravel as loose gravel can be

easily picked up and thrown by the auger

causing injury to the operator and/or damage

to the snow thrower.

AugerControl

Refer to AugerControlTeston page 13 to adjust the

auger control.

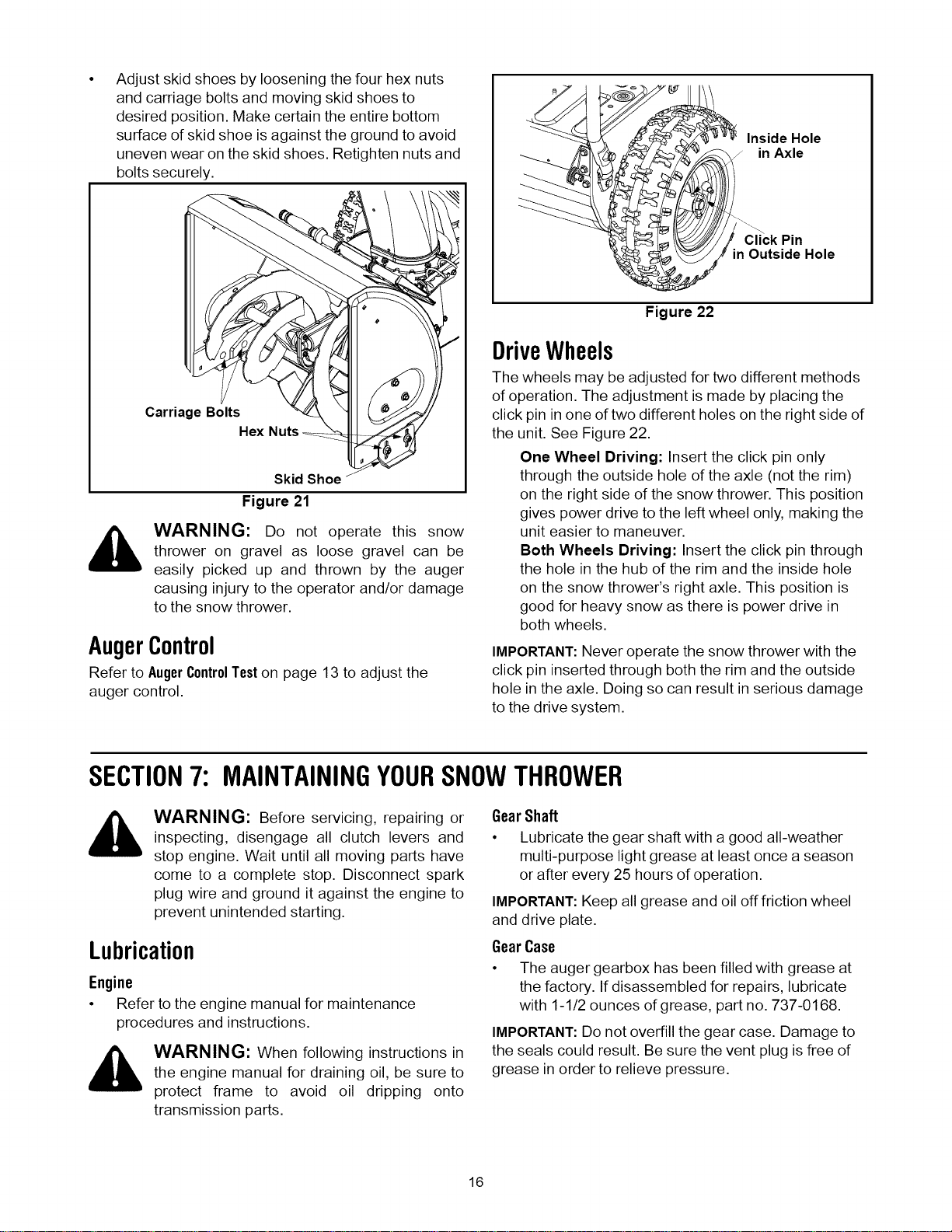

Inside Hole

/ in Axle

Click Pin

in Outside Hole

Figure 22

DriveWheels

The wheels may be adjusted for two different methods

of operation. The adjustment is made by placing the

click pin in one of two different holes on the right side of

the unit. See Figure 22.

One Wheel Driving: Insert the click pin only

through the outside hole of the axle (not the rim)

on the right side of the snow thrower. This position

gives power drive to the left wheel only, making the

unit easier to maneuver.

Both Wheels Driving: Insert the click pin through

the hole in the hub of the rim and the inside hole

on the snow thrower's right axle. This position is

good for heavy snow as there is power drive in

both wheels.

IMPORTANT:Never operate the snow thrower with the

click pin inserted through both the rim and the outside

hole in the axle. Doing so can result in serious damage

to the drive system.

SECTION7: MAINTAININGYOURSNOWTHROWER

WARNING: Before servicing, repairing or

inspecting, disengage all clutch levers and

stop engine. Wait until all moving parts have

come to a complete stop. Disconnect spark

plug wire and ground it against the engine to

prevent unintended starting.

Lubrication

Engine

• Refer to the engine manual for maintenance

procedures and instructions.

_, WARNING: When following instructions in

the engine manual for draining oil, be sure to

protect frame to avoid oil dripping onto

transmission parts.

GearShaft

• Lubricate the gear shaft with a good all-weather

multi-purpose light grease at least once aseason

or after every 25 hours of operation.

IMPORTANT:Keep all grease and oil off friction wheel

and drive plate.

GearCase

• The auger gearbox has been filled with grease at

the factory. If disassembled for repairs, lubricate

with 1-1/2 ounces of grease, part no. 737-0168.

IMPORTANT:Do not overfill the gear case. Damage to

the seals could result. Be sure the vent plug is free of

grease in order to relieve pressure.

16

Loading ...

Loading ...

Loading ...