Loading ...

Loading ...

Loading ...

9

The cooker should be connected to the

gas-supply by a

gas safe registered

installer.

Connection of the appliance to the gas

mains or liquid gas must be carried out according to

the prescribed regulation in force, and only after it is

ascertained that it is adaptable to the type of gas to

be used. If not, follow the instructions indicated in

the paragraph headed “Adaptation to different gas

types”. In the case of connection to liquid gas, by

tank, use pressure regulators that conform to the

regulation in force. The gas supply must be

connected to the left of the appliance. Be sure that

the hose does not pass through the rear of the

cooker touching hot parts.

Make sure the supply pressure conforms with the

values shown in the table entitled “Caracteristics of

the burners and nozzles”.

When the cooker is installed between

cabinets (recessed), the gas connection

must be effected by an approved flexible

hose with bayonet fitting

(BS 669 or EN 1480 0). The gas inlet for

the cookers is a threaded G 1/2 gas female

f i t t i n g .

Connecting the gas supply

To make the connection, a flexible hose should be

used corresponding to the current gas regulations

which are:

• the hose must never be at any point in its

lenght in contact with the “hot” parts

of the cooker;

• the hose must never be longer than 1,5 metre;

• the hose must not be subject to any tension

or torsional stress and it must not have any

excessively narrow

curves or bottlenecks;

• the hose must be easy to inspect along its

entire length to check its condition;

• the hose must always be in good condition,

never attempt to repair.

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of

gas with respect to the gas for which it was

produced

follow these steps:

a)a)

a)a)

a) replace the hose holder mounted on the

appliance with that supplied in the bag of “cooker

accessories”.

b)b)

b)b)

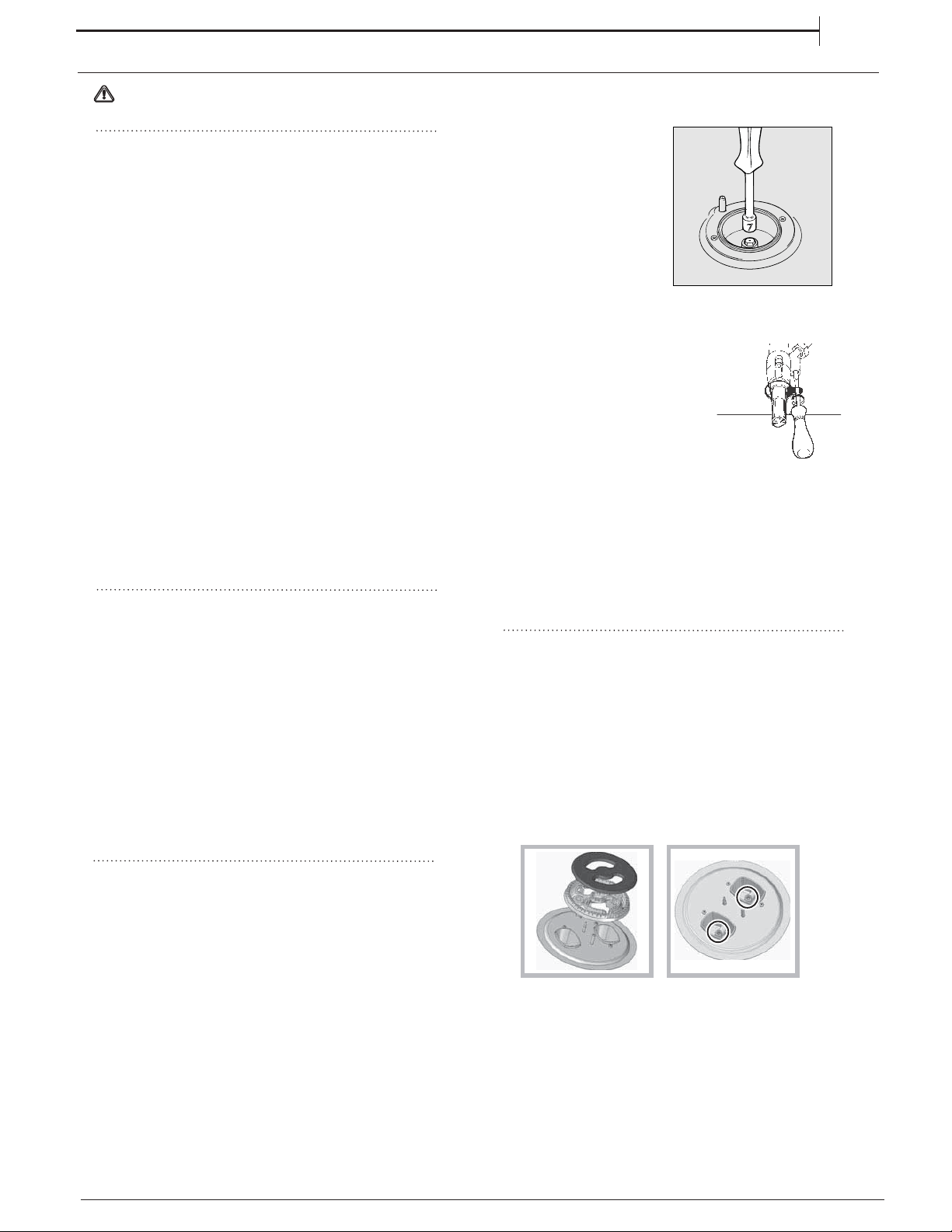

b) Replacing the burner nozzles on the hob:

•remove the grids and slide the burners from their

housings;

• unscrew the nozzles

using a 7 mm socket

spanner, and replace

them with nozzles for

the new type of gas

(see table 1 “Burner and

nozzle characteristics”).

•replace all the

components by

repeating the steps in

reverse order.

INSTALLATION TIPS

c )c )

c )c )

c ) Minimum regulation of the hob burners:

• turn the tap to minimum;

• remove the knob and adjust

the regulation screw, which is

positioned in or next to the tap

pin, until the flame is small

but steady.

In the case of liquid gas, the regulation screw

must be adjusted to the minimum setting.

• check that the flame does not turn off when

you turn the tap quickly from high to low.

d )d )

d )d )

d ) Regulating the primary air of the burners:

The primary air of the burners requires no regulation.

EN

WARNING : This operation must be perfomed

by a qualified technician

On completion of the operation, replace the old rating

sticker with one indicating the new type of gas used.

Replacing the Triple ring burner nozzles

1. Remove the pan supports and lift the burners out of

their housing. The burner consists of two separate

parts (see pictures).

2. Unscrew the nozzles using a 7 mm socket spanner.

Replace the nozzles with models that are configured

for use with the new type of gas (see Table 1). The

two nozzles have the same hole diameter.

3. Replace all the components by completing the

above operations in reverse order.

• Adjusting the burners primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust the adjustment screw,

which is positioned in or next to the tap pin, until the

flame is small but steady.

3. Having adjusted the flame to the required low

setting, while the burner is alight, quickly change the

position of the knob from minimum to maximum and

vice versa several times, checking that the flame

does not go out.

Gas connection

Loading ...

Loading ...

Loading ...