Loading ...

Loading ...

Loading ...

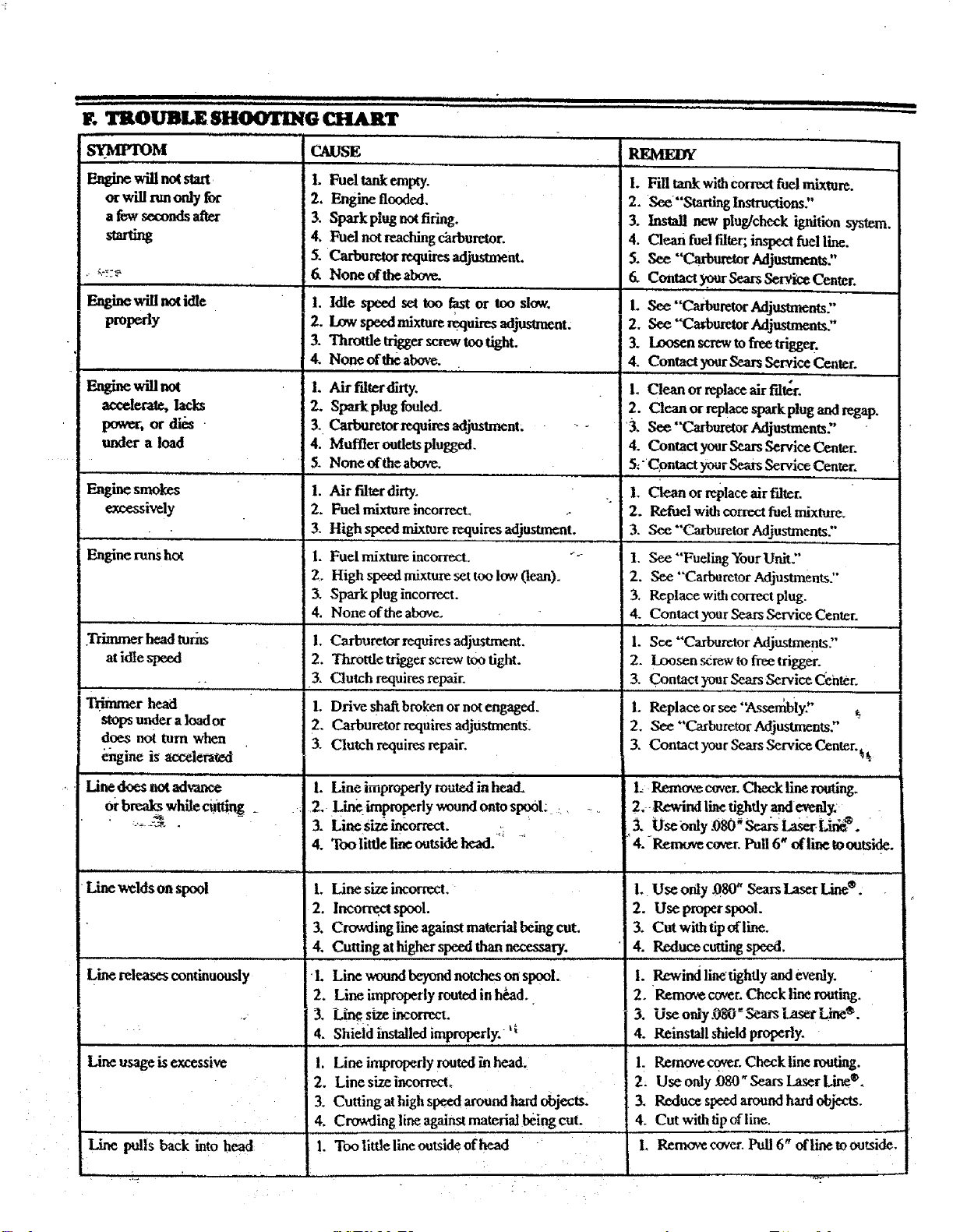

F. _X-itOuiIILlg $itiOOa_iLtqG (a-iART ......... °.....................

SXTVlVIOM

Englne wUtnotstart

or w'dlrunonly for

a few seconds after

starting

• _.-.--__

Engine will notidle

properly

Engi_ winnot

acoelerate, lacks

power, or di_

under a load

Engine runshot

.

3.

4.

..,.,

1.

2.

3.

4.

5.

Engine smokes 1.

excessively 2.

3.

Trimmer head turks

atidte speed

l,

2.

Tr'dnmerhead 1.

stops under aloador 2.

does not turn when 3.

engin_ is acce.lerated

,,,,,,,,,, , , , ,, ,

Linedoesnotad_

or

Line welds oa spool

,,,,,, ,,,,,,, ,,,,,,,,,,,,,,,,,,,,

Line releases continuously

Line usage is excessive

.U

CAUSE

L Fuel tank empty. I.

2. Engineflooded. 2.

3. Spark plug not firing. 3.

4, Fuel not reachingcarburetor. 4.

5. Carburetor requires adjustment. 5.

6.None oftheabove. 6,

I. Idle speed set too fastor too slow.

low speed mixturerequires adj_t.

Throttle trigger scow too tight.

None of the above.

Air filterdirty.

Spark plug f_uled.

Carburetor reqnires adjustment. -

Muffler outletsplugged.

None of theab<rce.

Air filterdirty. -. 1.

Fuel mixture incorrect. 2.

High speed mixture requiresadjustment. 3.

1. Fuel mixture incorrect. "- 1.

2. High speed mixturesettoo low (lean). 2.

3. Spark plug incorrect. 3.

4. None of the above. 4.

Carburetor requires adjustment.

Throttle trigger screw too tight.

Clutch requires repair.

Drive shaft brokenornot engaged.

Carburetor requires adjustments.

Clutch requires repair.

L Line improperly routed in head.

2. Line improperly wound onto spool: :, _

3.Line size incorrect. _;i..

4. Too little line outsidehead.

1. Line size _t.

2. lnco_ stx_l.

3. Crowding line against material being cut,

4.cutangat .....

"1. Line vamndbeyondnotches onspool,

2. Lineimproperlyroutedin h&ad.

3.Linesizeincorrect,

4. Shield installed improperly." t

1. Line improperly routedhahead. 1.

2. Line size incorrect. 2,

3: CuRing at high s_ around hard objects. 3.

4. Crowding line agains_material being cut. 4.

Line pulls back into head 1. Too little line outside ofhead

Fill tank with correctfuel mixture.

See "'StartingIns_ctions:'

Install new plug/check ignition system.

Clean furlfalter;inspectfuelline.

See '-cadmretor Adjustments:'

Contact_r SearsSeav_ Center.

1. See "-cadmretor Adjusanents:'

2. See Ca_uretorAdjustmen_

3. Loosen screw to free trigger.

4. Contact yourSears Sen, ice Center.

1. Clean or replaceair filter.

2. Clean or replace spark plug and legal).

3. See ''Carburetor Adjastmems:'

4. Contact yourSears Service Center.

5; Cgntact your _ Service Center.

Clean or replace air filter.

Refuel with correct fuel mixture.

See "'CarburetorAdjustments:"

See "'Fueling "fourUnit."

See *'CarburetorAdjustments.'"

Replace with correct plug.

Contact your Sea_ Service Center.

1. See "'Carburetor Adjustments:'

2- Loosen screw to free trigger.

3. Contact your Sears Service Cehter.

1. Replace or see '_ssenably:" _

2. See "'Carburetor Adjustments:

3. Contact your Sears Service Center._

2. ,Rewind line tightly madevenly:

3. Osebnly.080'SearsLaserLi_ ®.

4. Remove cover. Pull6" oflmetooutside.

1. Use only ,080" Sears Laser Hne ®.

2. Use proper spool.

3. Cut with tipof line.

4.R ,cec g m.

I. Rewind linefightly andevenly.

2. Remove cover. Check line routing.

3. Oseoniy.0_O_I_erLine ®.

4. Reinstall shieldproperly.

Remove cover. Check line routing.

Use ordy D80" Sears Laser Line®.

Reduce speedaround hard objects.

Cut with tip ofline.

L Remove cover. Pull6" ofline to outside.

Loading ...

Loading ...

Loading ...