Loading ...

Loading ...

Loading ...

GENERAL

This welder has been engineered to give

many years of trouble-free service

providing that a few very simple steps

are taken to properly maintain it.

1_ Keep the wire drive compartment lid

closed at all times unless the wire

needs to be changed or the drive

tension needs adiusting

2o Keep all consumables (contact tips,

nozzles, and gun liner) clean and

replace when necessary. See

CONSUMABLE MAINTENANCE

AND TROUBLESHOOTING later in

this section for detailed information_

3, Replace power cord, ground cable,

ground clamp, or gun assembly

when damaged or worn

4. Periodically clean dust, dirt, grease,

etco from your welder Every six

months or as necessary, remove

the side panels from time welder and

air-blow any dust and dirt that may

have accumulated inside the

welder.

Ddve Drive Gun

"{besion Tension Liner

Adiustmenl Arm

WARNING

ELECTRIC SHOCK CAN KILL! To

reduce the risk of electric shock, always

unplug the welder from its ac power

source before removing side panels.

IT IS VERY IMPORTANT TO MAINTAIN

THE CONSUMABLES TO AVOID THE

NEED FOR PREMATURE

REPLACEMENT OF THE GUN

ASSEMBLY

The GUN LINER is intended to provide

an unrestricted path for the welding wire

to flow through the gun assembly. Over

time it will accumulate dust, dirt, and

otller debris. RepIacement is necessary

when these accumulations begin to

restrict the free flow of wire through the

gun assembly

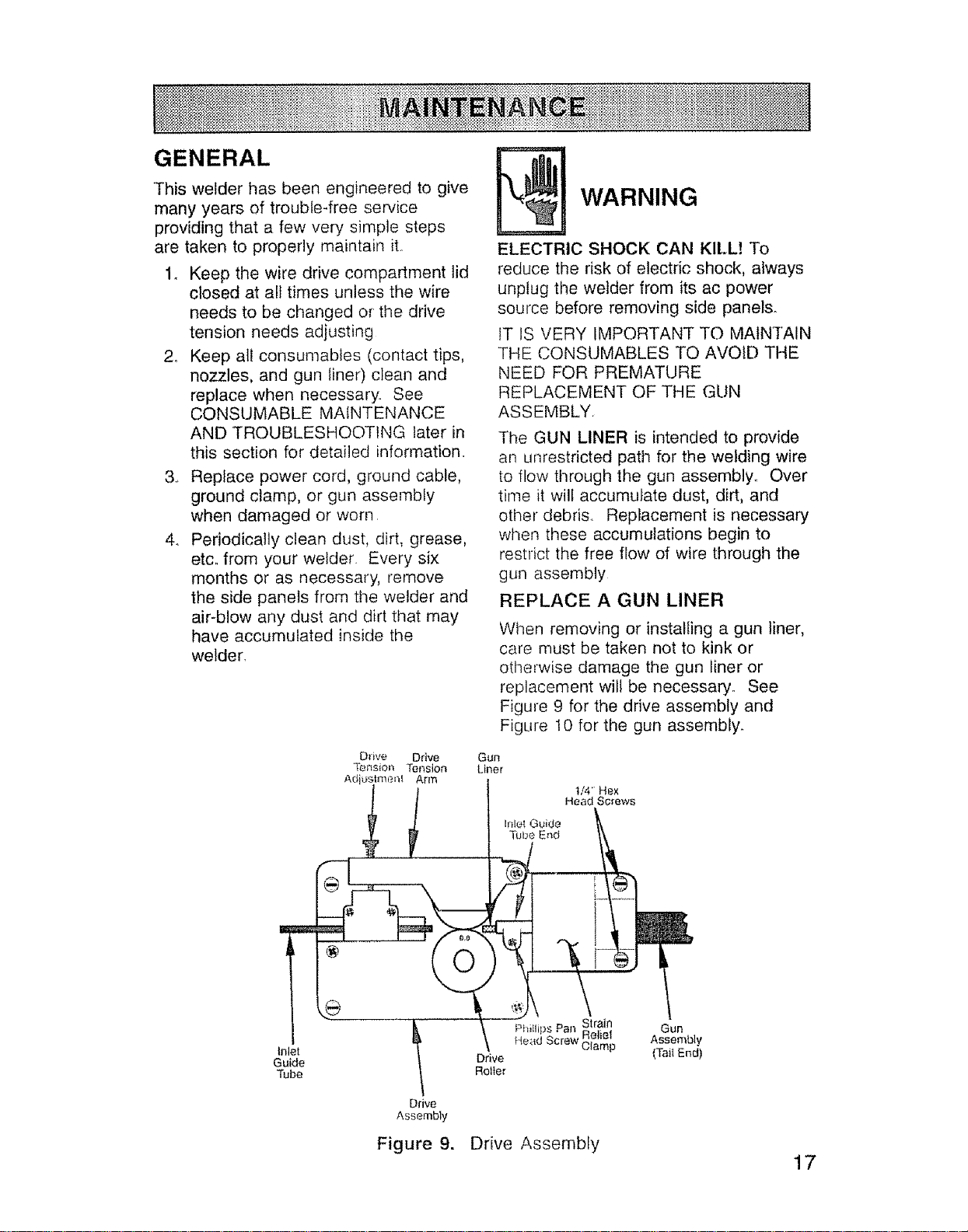

REPLACE A GUN LINER

When removing or installing a gun liner,

care must be taken not to kink or

otherwise damage the gun liner or

replacernent wilt be necessary. See

Figure 9 for the drive assembly and

Figure 10 for the gun assembly.

t/4" Hex

Head Screws

Irfle! Guide

Tube End

Inlet

Guide

Tube

Drive

Assembly

PMllips Pan Strain, Gun

llet_e!

\ Head Screw Clamp Assembly

Drive (Taii End)

Rotter

Figure 9. Drive Assembly

17

Loading ...

Loading ...

Loading ...