Loading ...

Loading ...

Loading ...

IMPORTANT - GAS CYLINDER SIZE

RESTRICTION! The tank tray you have

just installed on the back of tile welder

will handle gas cylinders no larger than

20 cubic feet., tf you select a cylinder

larger than 20 cubic feet, it must be

chained to a wall or other fixed support.

2

" 3

Figure 1, Mount Tank Tray Bracket

-Ib Welder

1.

2_

Align the four tank tray bracket (1)

mounting holes (as shown in Figure

1) with the four staked nuts on the

rear of the welder

Start one 1.4inch split lock washer

(2) and a 1A-20 x 1/2inch hex bolt (3)

in one of the top tank tray bracket

(1) mounting holes, then start each

of the other three split lock nuts (2)

and ¼-20 x 1/2inch hex bolts (3)

through the remaining mounting

holes.

3.. Tighten all four hex bolts..

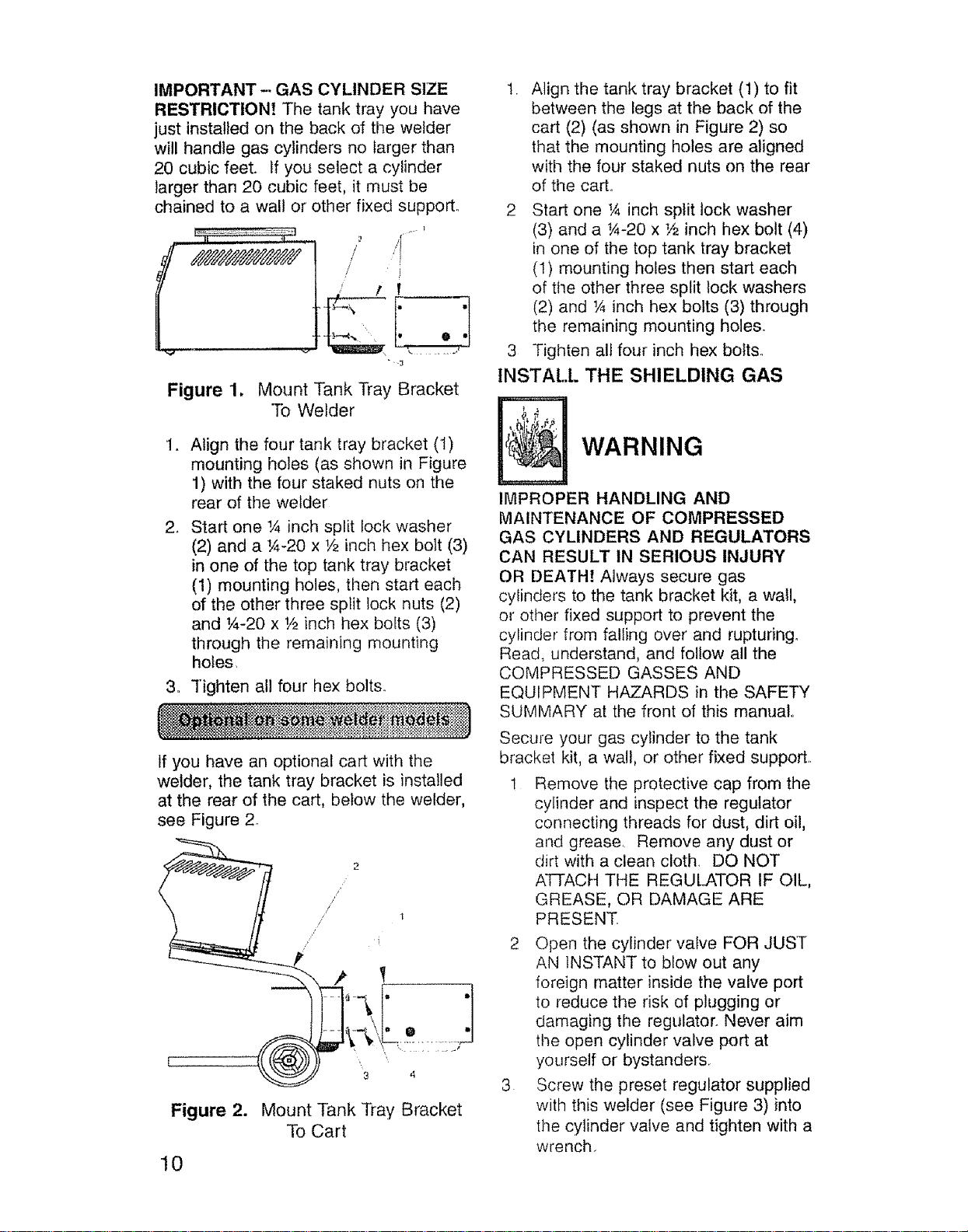

If you have an optional cart with the

welder, the tank tray bracket is installed

at the rear of the cart, below the welder,

see Figure 2

t

Figure 2.

2

/

/

1

I• :1

\

'3 4

Mount Tank Tray Bracket

To Cart

10

Align the tank tray bracket (1) to fit

between the legs at the back of the

cart (2) (as shown in Figure 2) so

that the mounting holes are aligned

with the four staked nuts on the rear

of the cart.

2 Start one ¼ inch split lock washer

(3) and a ¼-20 x Y2 inch hex bolt (4)

in one of the top tank tray bracket

(1) mounting holes then start each

of the other three split lock washers

(2) and ¼ inch hex bolts (3) through

the remaining mounting holes.

3 Tighten all four inch hex bolts°

INSTALL THE SHIELDING GAS

WARNING

IMPROPER HANDLING AND

MAINTENANCE OF COMPRESSED

GAS CYLINDERS AND REGULATORS

CAN RESULT IN SERIOUS INJURY

OR DEATH! Always secure gas

cylinders to the tank bracket kit, a wail,

or other fixed support to prevent the

cylinder" from falling over and rupturing°

Read, understand, and follow all the

COMPRESSED GASSES AND

EQUIPMENT HAZARDS in the SAFETY

SUMMARY at the front of this manual.

Secure your gas cylinder to the tank

bracket kit, a wall, or other fixed support,.

1 Remove the protective cap from the

cylinder and inspect the regulator

connecting threads for dust, dirt oil,

and grease. Remove any dust or

dirt with a clean cloth. DO NOT

ATTACH THE REGULATOR IF OIL,

GREASE, OR DAMAGE ARE

PRESENT.

2 Open the cylinder valve FOR JUST

AN INSTANT to blow out any

foreign matter inside the valve port

to reduce the risk of plugging or

damaging the regulator° Never aim

the open cylinder valve port at

yourself or bystanders.

3 Screw the preset regulator supplied

with this welder (see Figure 3) into

the cylinder valve and tighten with a

wrench..

Loading ...

Loading ...

Loading ...