Loading ...

Loading ...

Loading ...

CUTTINGCROWNMOLDING

Thecompoundmitersawdoesanexcellentjobof cut=

tingcrownmolding.Hngeneral,compoundmitersawsdo

abetterjobofcuttingcrownmoldingthananyothertool

made.

Hnordertofit properly,crownmoldingmustbecompound

miteredwithextremeaccuracy.

Thetwocontactsurfacesonapieceofcrownmolding

thatfit flatagainsttheceilingandthewallofa roomareat

anglesthat,whenaddedtogether,equalexactly90. Most

crownmoldinghasatop rearangle(thesectionthatfits

flatagainsttheceiling)of 52 andabottomrearangle(the

sectionthatfitsflatagainstthewall)of 38.

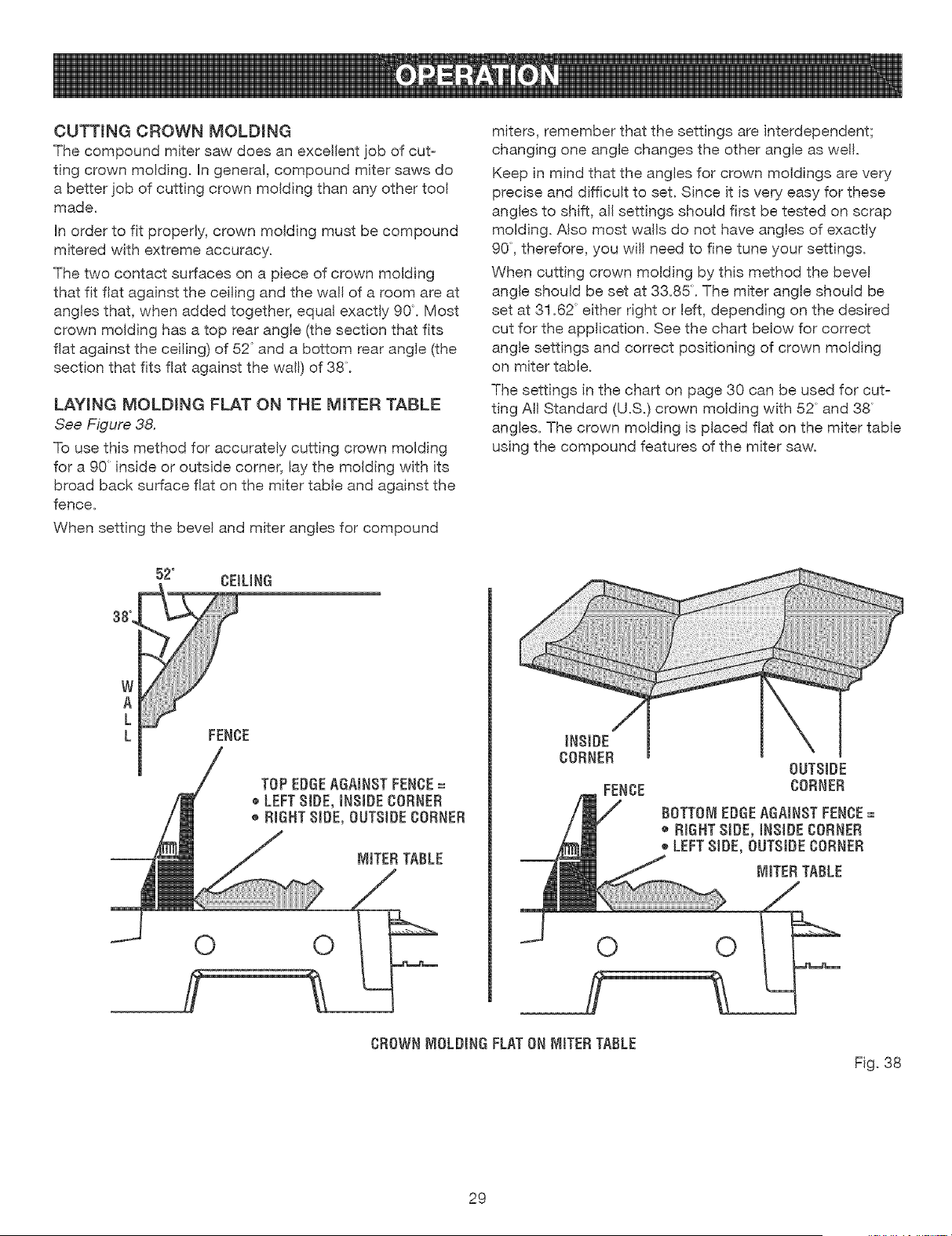

LAYINGMOLDINGFLATONTHE MITERTABLE

See Figure 38.

To use this method for accurately cutting crown molding

for a 90 inside or outside corner, lay the molding with its

broad back surface flat on the miter table and against the

fence.

When setting the bevel and miter angles for compound

miters, remember that the settings are interdependent;

changing one angle changes the other angle as well.

Keep in mind that the angles for crown moldings are very

precise and difficult to set. Since it is very easy for these

angles to shift, all settings should first be tested on scrap

molding. Also most walls do not have angles of exactly

90, therefore, you wil! need to fine tune your settings.

When cutting crown molding by this method the bevel

angle should be set at 33.85:. The miter angle should be

set at 31.62 either right or left, depending on the desired

cut for the application. See the chart below for correct

angle settings and correct positioning of crown molding

on miter table.

The settings in the chart on page 30 can be used for cut=

ting A!! Standard (U.S.) crown molding with 52 and 38

angles. The crown molding is placed flat on the miter table

using the compound features of the miter saw.

52° CEILING

A ....

k

L FENCE

TOP EDGEAGAINSTFENCE=

e LEFTSIDE, iNSIDE CORNER

® RIGHT 81DE,OUTSIDECORNER

0 0

CROWNWIOLDINGFLAT ONMITERTABLE

Fig. 38

29

Loading ...

Loading ...

Loading ...