Loading ...

Loading ...

Loading ...

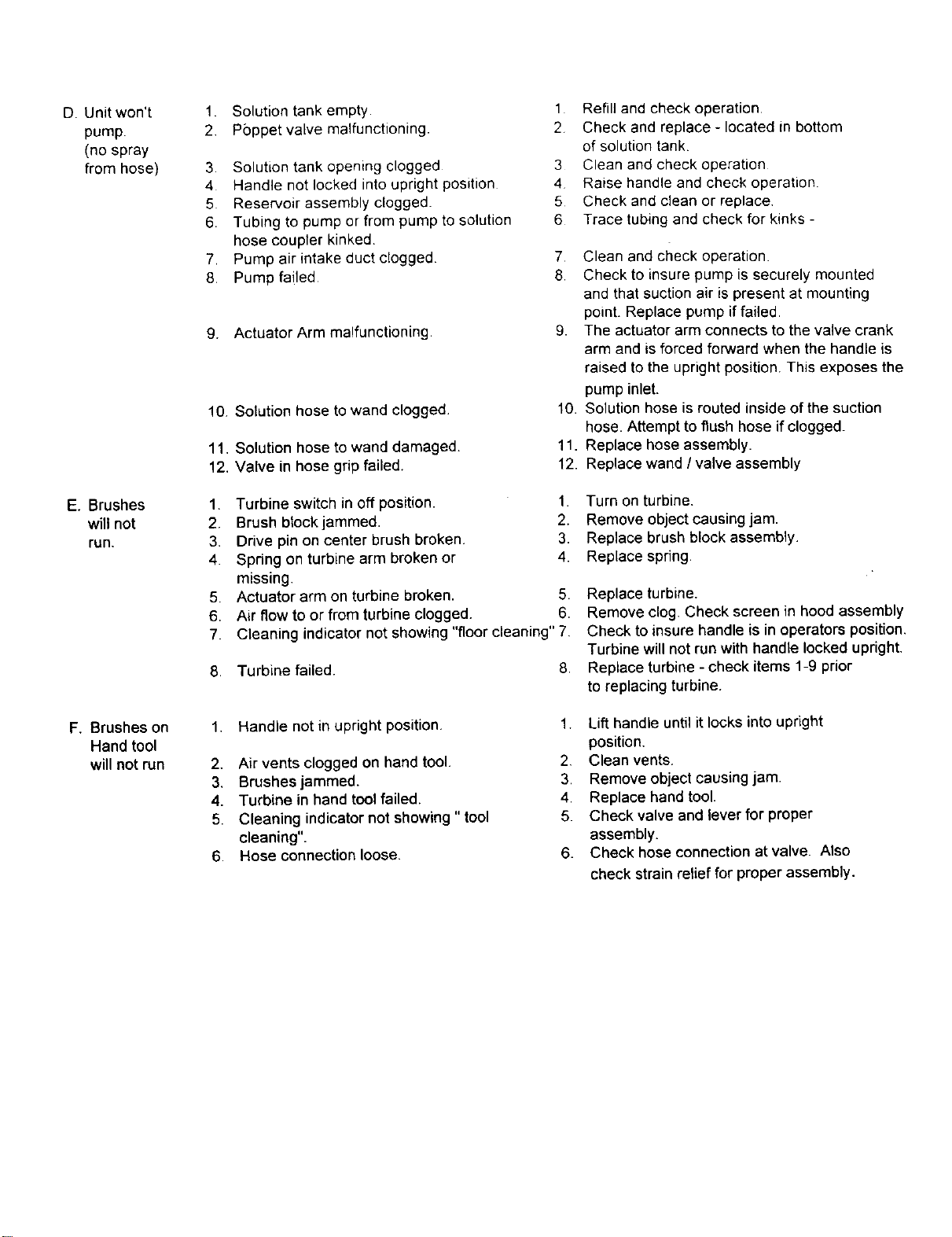

D.Unitwon't

pump.

(nospray

fromhose)

1. Solutiontankempty

2 Poppetvalvemalfunctioning.

3 Solutiontankopeningclogged

4 Handlenotlockedintouprightposition

5 Reservoirassemblyclogged.

6. Tubingtopumporfrompumptosolution

hosecouplerkinked

7. Pumpairintakeductclogged.

8. Pumpfailed

9. ActuatorArmmalfunctioning.

10.Solutionhosetowandclogged.

11.Solutionhosetowanddamaged.

12.Valveinhosegripfailed.

1 Refill and check operation

2 Check and replace - located in bottom

of solution tank

3 Clean and check operation

4 Raise handle and check operation

5 Check and clean or replace

6 Trace tubing and check for kinks -

7 Clean and check operation.

8 Check to insure pump is securely mounted

and that suction air is present at mounting

point. Replace pump if failed.

9. The actuator arm connects to the valve crank

arm and is forced forward when the handle is

raised to the upright position. This exposes the

pump inlet.

10. Solution hose is routed inside ofthe suction

hose. Attempt to flush hose if clogged.

11. Replace hose assembly.

12. Replace wand / valve assembly

E. Brushes

will not

run.

1. Turbine switch in off position.

2. Brush block jammed.

3. Drive pin on center brush broken.

4. Spring on turbine arm broken or

missing.

5. Actuator arm on turbine broken. 5.

6. Air flow to or from turbine clogged. 6.

7. Cleaning indicator not showing "floor cleaning" 7

8. Turbine failed.

1. Turn on turbine.

2. Remove object causing jam.

3. Replace brush block assembly,

4. Replace spring.

8.

Replace turbine.

Remove clog. Check screen in hood assembly

Check to insure handle is in operators position.

Turbine will not run with handle locked upright.

Replace turbine - check items 1-9 prior

to replacing turbine.

F. Brushes on

Hand tool

will not run

1, Handle not in upright position.

2. Air vents clogged on hand tool.

3, Brushes jammed.

4. Turbine in hand tool failed.

5. Cleaning indicator not showing "tool

cleaning".

6. Hose connection loose.

1. Lift handle until it locks into upright

position.

2 Clean vents.

3. Remove object causing jam.

4. Replace hand tool.

5. Check valve and lever for proper

assembly.

6. Check hose connection at valve. Also

check strain relief for proper assembly.