Loading ...

Loading ...

Loading ...

Part number 550-100-252/0520

– 49 –

Control operation and setup (continued)

Control Priorities & Input/Outputs

• For heating installations with multiple systems, the Control uses

PRIORITIES to determine the order of operation of the systems.

The control’s MAX and MIN time settings determine the maxi-

mum and minimum times a system will be operated before being

turned off to allow another system to operate. A typical example

is DHW priority — heat demand from the DHW system is given

preference over space heating, if set to use Priority 1.

• Each PRIORITY has its own set of operating parameters. The

control prompts the user to select the system type (finned tube

baseboard, DHW, etc.) and is factory programmed with param-

eters suited to each of these system types. The user can also choose

CUSTOM to create a system type.

• The Control provides up to three priorities for single boiler

applications and up to four priorities for network boiler ap-

plications. The order of operation is: PRIORITY 1, PRIORITY

2, PRIORITY 3.

• The 120VAC power output to the boiler circulator is provided by

a relay located on the boiler’s Pump/Communications Board. For

each of the priorities, the control can be setup to run the boiler

pump or to leave it off. It is recommended to set Blr Circ to OFF

for DHW that is directly piped with its own DHW Circ.

• Each boiler has three input/output pairs (INPUT/OUTPUT 1,

2 and 3. Control setup prompts the user to assign each of these

I/O pairs to a PRIORITY. The Control then knows which system

(priority) to operate when the input receives a call for heat. On

a call for heat to an input, the Control closes the corresponding

output (120VAC) and begins controlling the boilers according

to the setup for the assigned priority.

• The MAX ON TIME setting controls the maximum time a prior-

ity will be allowed to run before switching to a lower priority’s call

for heat. The MIN ON TIME setting controls the minimum time

a priority will be operated before switching to a higher priority’s

call for heat, or the next lower priority.

• When multiple inputs are set up on the same priority, they will

run at the same time if the priority and inputs are active.

Control operation

• The control responds to signals from:

• Room thermostats.

• DHW aquastats (if used).

• Temperature sensors (boiler return, boiler supply, flue tem-

perature) and, when used, system supply and system return,

outdoor temperature).

For optimal performance, it is

recommended to install the system supply and return

sensors.

• The control automatically adjusts blower speed (and gas flow

rate) to match boiler output to space heating and/or DHW

heating demand.

• The control provides three inputs and three outputs (for circula-

tors or auxiliary devices) plus a fourth boiler circulator output.

• The outdoor temperature is used for supply temperature reset

operation and for the warm weather shut down (WWSD) option.

• System presets:

• The Control provides presets by system type (see

Figure 33, page 54 for complete list).

Setting Up the Boiler

Step 1

• DETERMINE input/output needs –

• What are the inputs? – Thermostats, remote

contacts, end switches, etc.

• What does each control’s output need to do? –

operate a pump, activate an air louver, etc.

Step 2

• Install the boiler following all instructions in the

SVF

TM

Boiler Manual before proceeding further.

• Connect wiring to the control inputs and outputs

to accomplish the purposes set in Step 1.

Step 3

• Follow instructions in the Boiler Manual to start

up and power the boiler.

Step 4

• Use the WIZARD (below) or enter control

parameters manually (skip Wizard).

Control WIZARD

• The Wizard is available on initial setup of the boiler. It leads

through a step-by-step setup procedure designed for the

application chosen.

• Context-sensitive help is available to explain the purpose

of key setup items.

• Advanced settings for single boiler applications can be ac-

cessed manually from the Contractor menu.

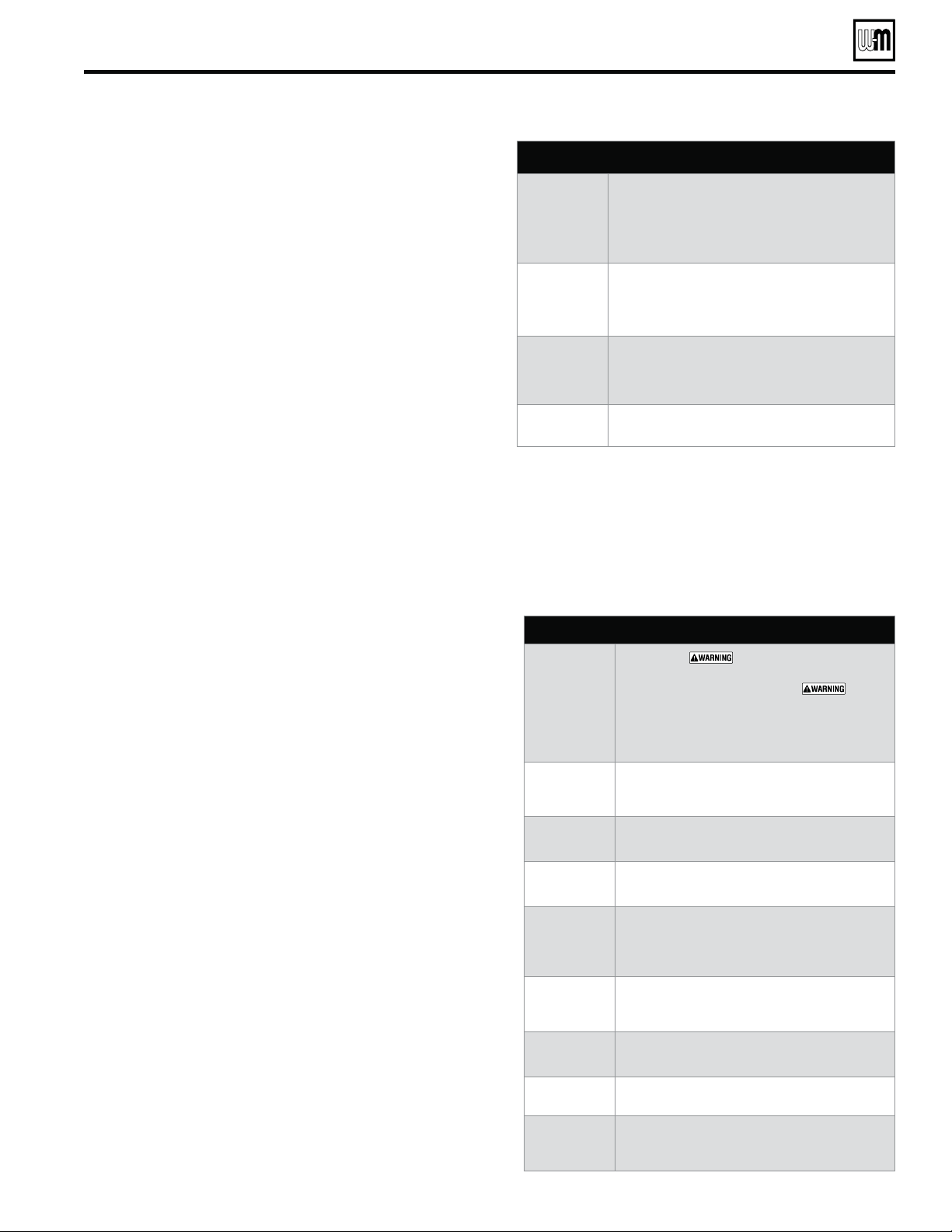

WIZARD Sequence

Boiler

Settings

• Altitude –

– must be set correctly for

proper operation.

• Fuel (natural gas or propane) – – must

be set correctly for proper operation – control

will pause until this value is selected.

• WWSD – set outdoor temperature above

which space heating will be deactivated.

Inputs/

Outputs

• Select the usage of inputs 1, 2 and 3.

• Determine usage of outputs 1, 2 and 3

(outputs correspond to inputs).

Set

Priorities

• Assign priorities 1, 2 and 3 to the inputs.

System

Settings

• Set system settings or leave at their defaults.

System

Types

• Specify what system type is connected to

each of the three outputs; each system

type causes the control to preset. operating

temperatures.

Output

Activation

• (When applicable) Select when to activate AUX

PUMP/OUTPUT – by input, always on, external

switch, etc.

Priority

Switching

• Set maximum and minimum timings for

priorities.

Date/Time

• Set date and time – important for control

diagnostic logging.

Information

• Set installer name and contact information.

• Enter CP#, install date, maintenance date, etc.

• Set automatic maintenance notification timing.

Control operation and setup (continued)

SVF

™

Series 1

COMMERCIAL CONDENSING GAS-FIRED WAT ER BOILER

— Advanced Manual

Loading ...

Loading ...

Loading ...