Loading ...

Loading ...

Loading ...

25

INSTRUCTIONS FOR THE INSTALLER

Hot Plate Ignition Failure

• Check alignment of burner holes to electrode.

• Check aeration sleeve for adjustment for gas type,

location and ambient conditions.

• No spark, check ignition box failure or power supply.

Before Leaving

• Check all connections for gas leaks with soap and

water. DO NOT use a naked ame for detecting

leaks. Ignite all burners to ensure correct operation

of gas valves, burners and ignition.

• Turn gas taps to low ame position and observe

stability of the ame. When satised with the cooker,

please instruct the user on the correct method of

operation.

• In case the appliance fails to operate correctly

after all checks have been carried out, refer to the

authorised service provider in your area.

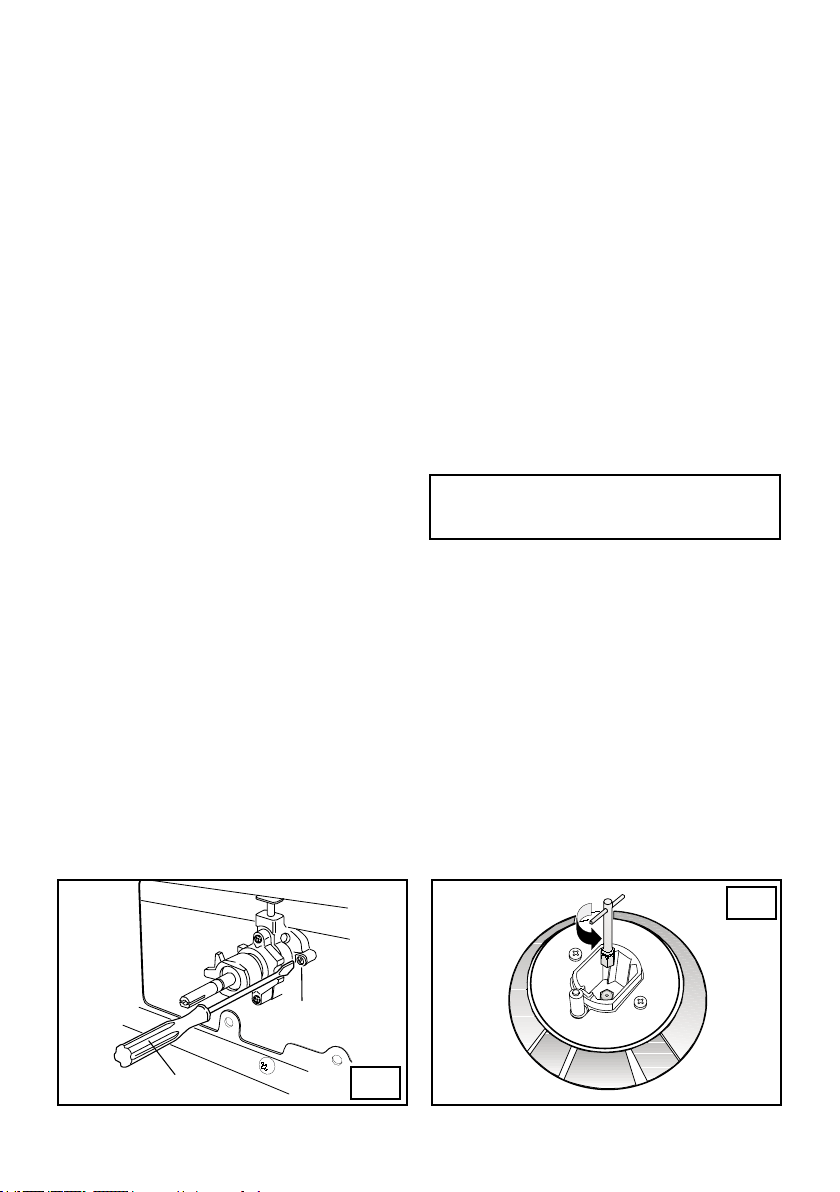

OVEN BURNER (g. 21)

The burner is installed on the oven base and is covered

by the bottom plate which must always remain in that

position during oven operation,

To adjust the primary air, is performed when the

burner is ignited, by adjusting the sleeve (B) and

unscrewing screw (A). Lock screw (A) in place once

the adjustments have been made.

CHANGING THE FLEXIBLE GAS HOSE

In order to guarantee that the gas hose is always in

excellent condition we strongly recommend changing

it on the date you will nd printed on it.

GAS CONVERSIONS

REPLACING THE INJECTORS

Our burners can be adapted to different types of gas

by simply installing the injectors suitable for the gas

you want to use. To help the installer, the table (see

TECHNICAL FEATURES

paragraph) gives the burner

nominal heat input, injector diameter and operating

pressure of the different gas types.

Comply with the following instructions:

Injector replacement - Hob burners.

To change the injectors on the hob, remove the burner

cup and head and with a 7 mm Ø socket

spanner replace them (fig. 22).

After having replaced the injectors, it will be

necessary to proceed with burner adjustment as

explained in the previous paragraphs.

20

22

Loading ...

Loading ...

Loading ...