Loading ...

Loading ...

Loading ...

C. OPERATINGTIPS

Asyou becomefamiliarwithyouredger,youwillbeai0teto

determineyourownpaceforusingit.Conditionssuchas

depthofcutandmaterialbeingcutwillregulatethespeed'

andtimerequiredforyouredgingjob.

• i. Increasetheenginespeadbeforapiaclngtheblsde

in the cut. AllowengInetowarmupforone minute

beforeyoubeginedging,

2. RuntheengineatfullthmtUewhilecuffingforbast

operation,

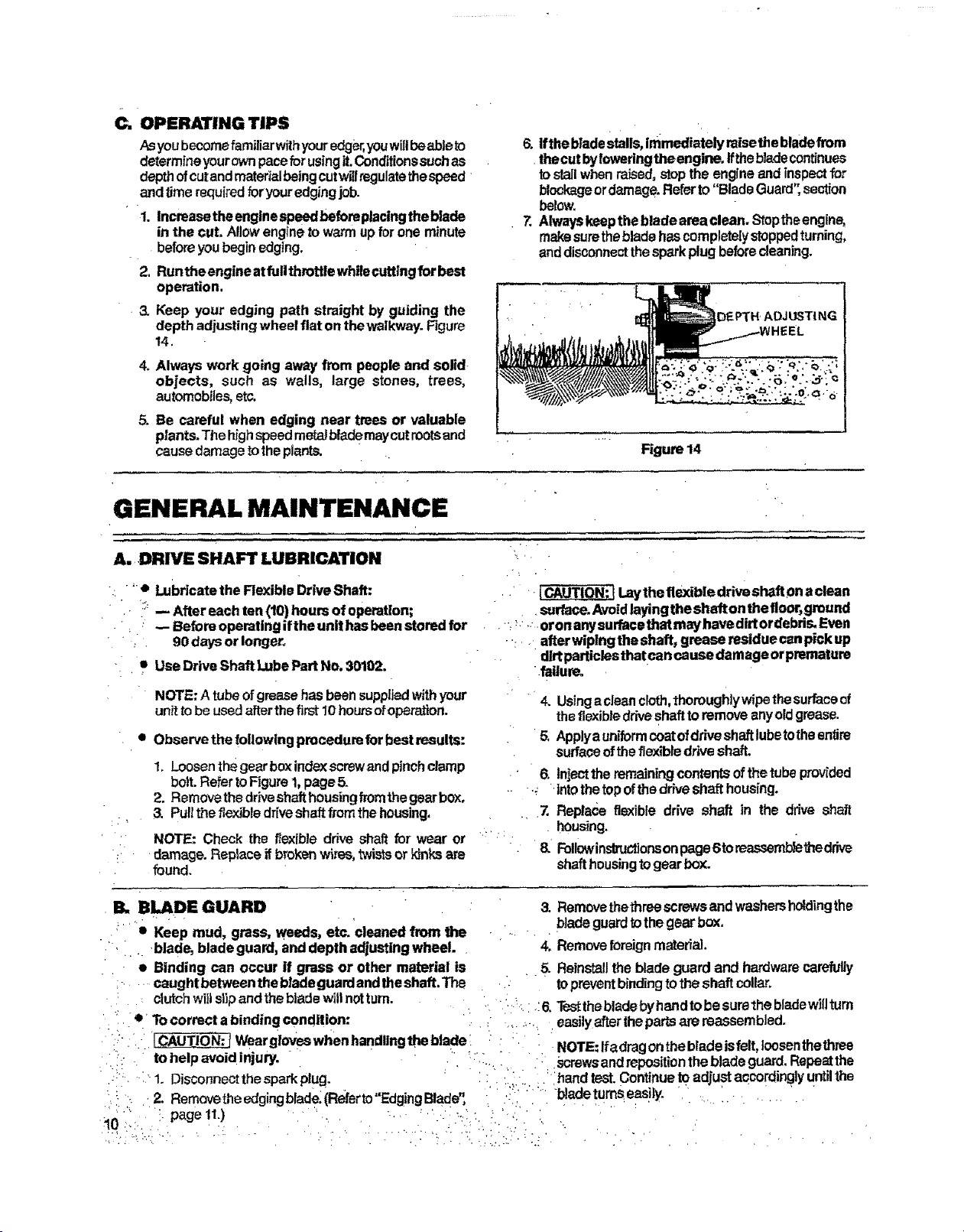

.3. Keep your edging path straight by guiding the

depth adjustingwheel fiat onthewalkway.Figure

14.

4. Always work going awayfrom people and solid-

obiects, such as walls, large stones, trees,

automobiles, etc,

5. Be careful when edging near trees or valuable

plants.The highspeedmetalblademaycutrootsand

causedamagetotheplant_

6. ifthe bPadestalls,immediatelyraisethebladefrom

thecutbylowering theengine,ifthebladecontinues

tostallwhenraised,stopthe englneand inspectfor

blockageordamage.Referto"BladeGuard',section

below.

7. Alwayskeepthe bladeareaolean. Stoptheengine,

makesurethebladehascompletelystoppedturning,

anddisconnectthespark plugbeforecleaning.

DEPTH" ADJUSTING

Figure14

GENERAL MAINTENANCE

A. ,DRIVE SHAFT LUBRICATION

' o Lubricatethe Rexible DriveShaft:

;;:-- After eachten(10)hoursof operation;

. "• -- Before operating ifthe unithas beenstoredfor

• 90daysor longer.

/ |CAUTIONi tLaythe flexible driveshaft0naclean

surface.Avoidlayingtheshafton theflo0r,ground

, _: oronanysurfacethatmayhavedirtordebd_Even

..... afterwiplngtheshaft, grease restduecanpick up

• UseDriveShaft LubePartNo. 30102.

NOTE:A tubeofgreasehasbeensuppliedwithyour " r

unittobe usedafterthefirst 10hoursor=operation.

• Obser/e the following precedurefor bestresults:

1=Loosenthegearboxindexscrewandpinchclamp

bolt. Refer toFigure1,page5-

2. Removethedriveshafthousingfromthegearbox.

3 PulttheflexJbledrfveshaftfromthehousing, ..

• ' NOTE: Check theflexibledriveshaftforwearor '"

-. .damage.Replaceifbrokenwires,twistsorkinksare

found.

• B,, |LADE GUARD

,:" • Keep mud, grass, weeds, etc. cleanedfrom the

:. .. blade, bladeguard, anddepth adjustingwheel. •

• Binding can occur if grass or other material is

;...... eaughtbetween thebtadeguardandtheshaft.The

dirtparticlesthatcan causedamage orpremature

.failure.

• 4. Usingacleancloth,thoroughlywipethesurfaceof

theflexible driveshafttoremove enyoldgrease.

5, Applyauniformcoatofdriveshaftlubetotheentire

surfaceoftheflexibledriveshaft.

6. Injecttheremainingcontentsofthetubeprovided

---: 'into thetopofthedriveshafthousing.

Z Replace flexible drive shaft in the ddve shaft

. housing.

8. Followinstructionsonpage6 toreassemb_ethedrive

shafthousingtogearbox.

3. RemovethethreescrewsandwashershOtdingthe

bladeguardtothegear bc0(.

4. Removeforeignmaterial.

• .. 5- Reinstallthebladeguard and hardwarecarefully

... topreventbindingtothe shaft collar.

clutchwlilslipand theblade willnottum. • .-_:..:6. Testthebladebyhandtobesurethebladewillturn

=' r " e >TOcorrect abindingcondition: " r easilyafterthepartsare reassembled.

ii- " I.CAUTIO_NEtWeargloveswhenhandtingthebladel : ' :_. i NOTE:lfadragonthebladeisfeft, toosenthethree

.!': . to helpavoidinjury. " " "........

• . ' ...... ' screwsandrepositionthebladeguard.Repeatthe

'. _r_+• :'1. Discennectthesparkplug. , " :: . '.iii. : ;ihandtest.Oontinue_ad_ustaccordinglyuntilthe

, ,, bladetumseas ly

.i !:i' 2. Removetheedgingblad_:(RefertoEdgingBlade, .".';i, •,+ "''" J " _ _ " ' r ' " + = r ...... T

1

Loading ...

Loading ...

Loading ...