Loading ...

Loading ...

Loading ...

Part number 550-100-260/0520

23

ECO

®

Tec

GAS-FIRED WATER BOILER – 80/110/150/199 BOILER MANUAL

Venting & air — general (continued)

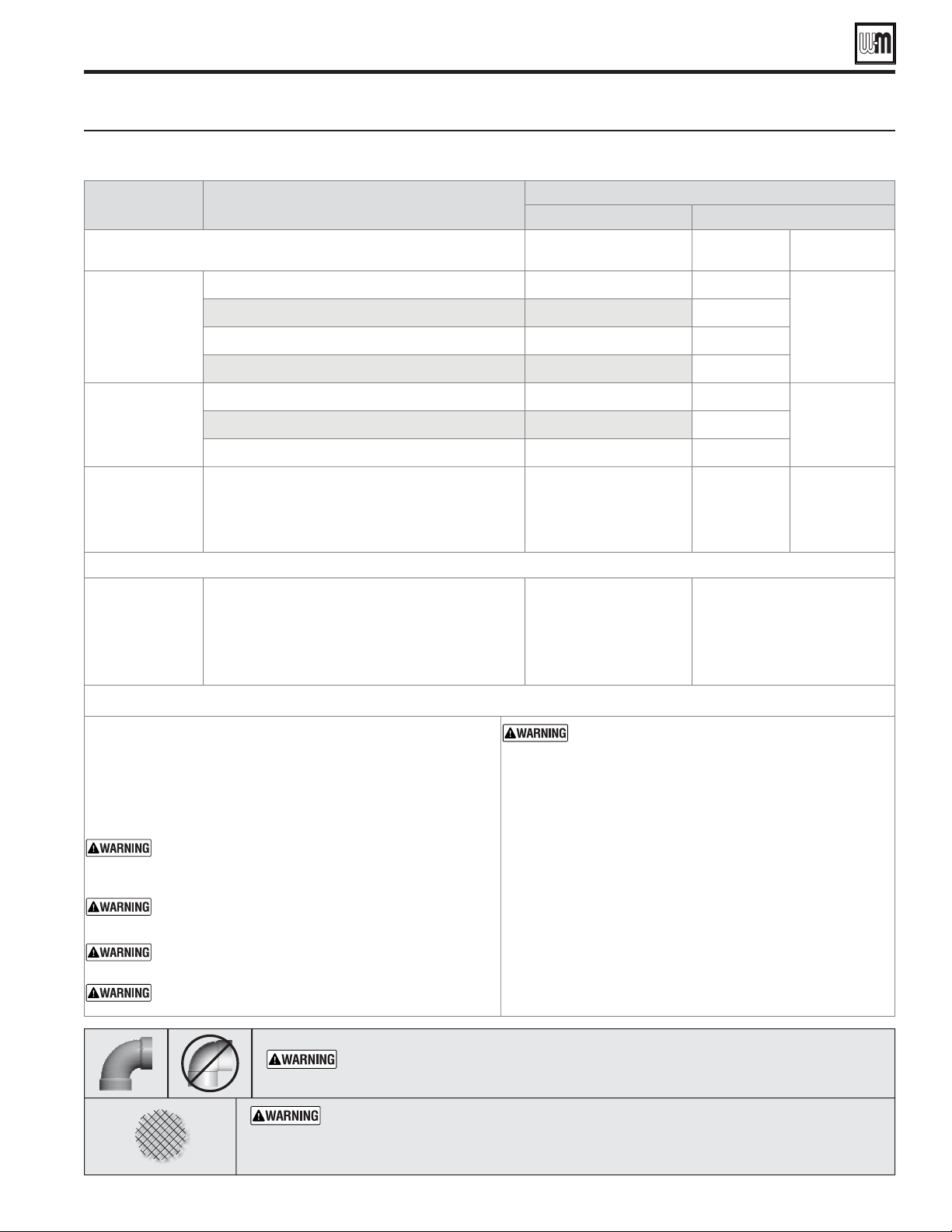

Vent and air piping materials — Use only the materials listed below, ensuring that all materials meet

local codes (see Figure 125, page 137 for part/kit numbers)

ALL vent and air pipes require a BIRD SCREEN at each termination. Most kits do not include

the bird screens. Purchase bird screens separately from Weil-McLain or vent kit supplier if

not included. [Note — bird screening is integral to the 3" PVC Weil-McLain sidewall vent

cap,

available for purchase from Weil-McLain

. No additional screening is required.]

USE SWEEP ELBOWS FOR ALL VENT AND AIR PIPING — DO NOT use short radius

elbows for vent or air piping. Boiler performance could be a ected.

(Note 2)

&

PVC schedule 40 (Note 1) ANSI/ASTM D1785 ULC S636

ABS,

PVC, PVC-DWV,

CPVC or

polypropylene

PVC-DWV schedule 40 (Note 1) ANSI/ASTM D2665 N/A

CPVC schedule 40 (Note 1) ANSI/ASTM F441 ULC S636

ABS-DWV schedule 40 (Intake Only) ANSI/ASTM D2661 ULC S636

PVC (Note 1) ANSI/ASTM D2564/F656 ULC S636

Use only cement

and primer

suitable for piping

material used

CPVC (Note 1) ANSI/ASTM F493 ULC S636

ABS schedule 40 (Note 1) ANSI/ASTM D2235 ULC S636

Obtain all materials from M&G

Simpson-Duravent

®

Obtain all materials from Centrotherm

Note: See

page 137 for correct appliance adapters to be used.

See manufacturer’s literature for

detailed information

MUST USE LOCKING

COLLAR ON EVERY JOINT

ULC S636

PVC, PVC-DWV,

CPVC or

polypropylene

Heat Fab, Inc. — Saf-T-Vent

®

Z-Flex, Inc. — Z-Vent II

Dura-Vent — FasNSeal™

Metal-Fab, Inc. — CORR/GUARD

See Figure 125, page 137 for Mfg's adapter

part numbers.

Certifi ed for Category IV and

direct vent appliance venting

Certifi ed for Category IV and direct

vent appliance venting

(purchase separately) — see Figure 125, page 137 for part numbers.

Note 1: Weil-McLain concentric vent kits are made from PVC

pipe and ttings.

Note 2: System 636 PVC concentric terminations utilize PVC

pipe/ ttings certi ed to ULC S636.

If ULC S636 compliance is required, use only System 636

pipe, ttings and cement.

DO NOT mix piping from di erent pipe manufacturers

unless using adapters speci cally designed for the purpose

by the manufacturer.

Every joint on polypropylene vent piping must include

a locking collar.

DO NOT use cellular core PVC (ASTM F891), cellular core

CPVC, or Radel

®

(polyphenolsulfone) in venting systems.

DO NOT cover non-metallic vent pipe and ttings with

thermal insulation.

ADAPTERS — The boiler comes with a 3" 3-in-

1 adapter as standard. This adapter allows the

installation of 3" PVC schedule 40, CPVC schedule

40, PVC-DWV schedule 40, AL29-4C stainless steel

(from Simpson-Duravent only) and Polypropylene

(from Simpson-Duravent & Centrotherm only)

piping without the need for extra adapters.

ADAPTERS – It may require additional adapters at the

terminations if using di erent venting materials.

(When going from PP to the Weil-McLain side wall

plate, for example).

ADAPTERS - If using 2" piping, where approved for

the application, provide adapters for a 3" pipe

material (mentioned above) connections and at

the terminations, if required.

Loading ...

Loading ...

Loading ...