Loading ...

Loading ...

Loading ...

Part number 550-142-330/0421

16

SGO

OIL-FIRED NATURAL DRAFT STEAM BOILER — SERIES 4 — Boiler Manual

SERVICETECHNICIANONLY—readandfollowcompletely.

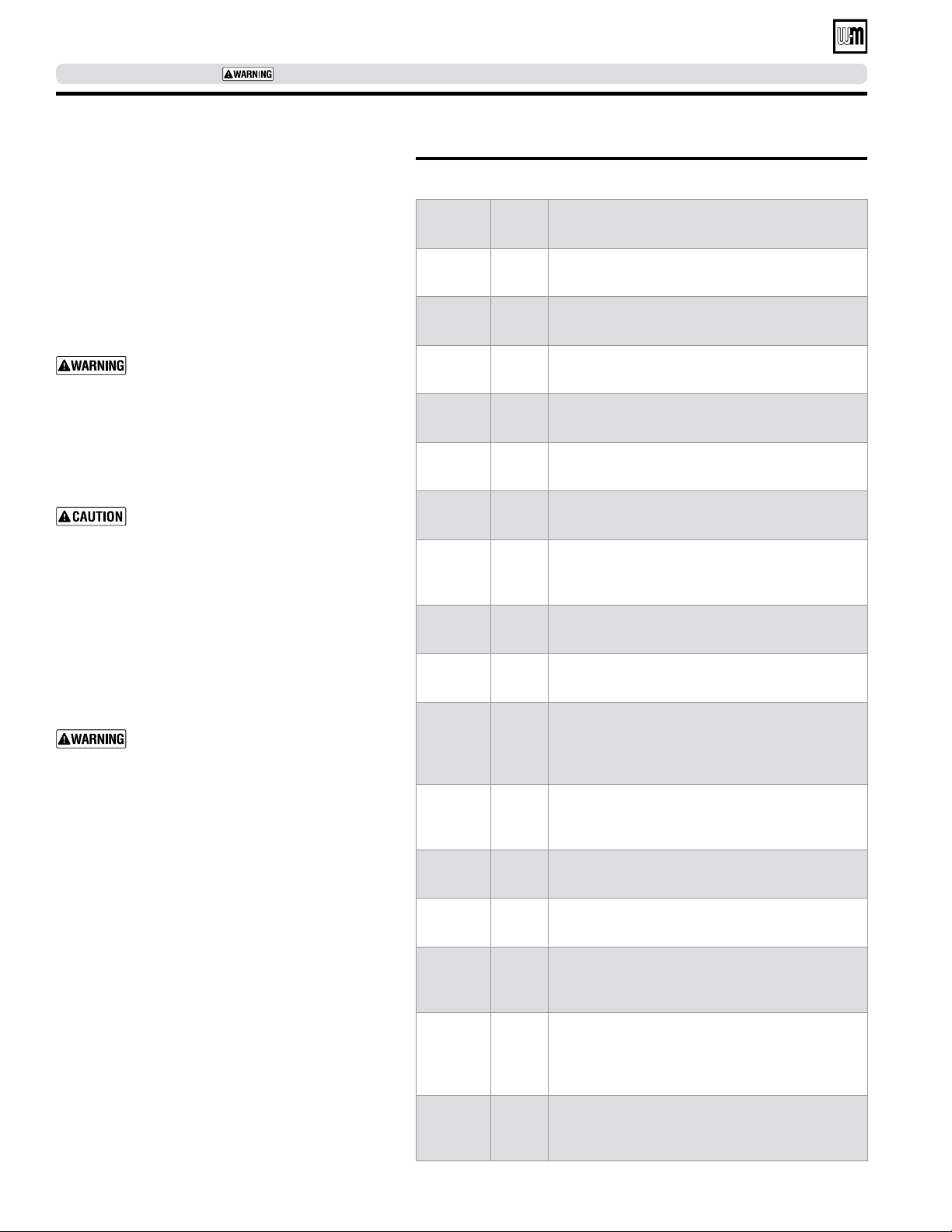

LocationSizeFunction

A1 1½" Skim tapping

A2 2½" Supply piping (sizes 3 - 9)

A3 2½" Supply piping (sizes 6 - 9)

B1 1½" Plugged

B2 2" Return piping

E1 & E2 ½" Float LWCO

E1 ½"

Steam pressure gauge and limit

Control when using probe LWCO

E2 ½" Plugged when using probe LWCO

H ¾" Drain valve

L ¾"

Steam pressure gauge and limit

Control when using float LWCO

Plugged when using probe LWCO)

P ¾" Probe LWCO (plugged when using float LWCO)

R ¾" Relief valve

S1 & S2 ½" Gauge glass

U1 1"

Indirect-fired water heater/ hot water

baseboard supply

U2 ¾"

Operating control for tankless heater (sizes

6-9) or operating control for indirect-fired water

heater (sizes 3-9)

U3 ¾"

Operating control for tankless heater (located

in heater plate — sizes 3-5)

Perform hydrostatic pressure test

1. Refer to Figure 7 and Control Tapping Table 3, to

install:

a. Boiler drain.

b. Water pressure gauge (test only). Be sure gauge

can handle test pressure.

c. Air vent in tapping on top of boiler.

d. Plugs in remaining tappings.

2. Fill boiler. Vent all air. Pressure test boiler at 45-55

psig.

Do not leave boiler unattended. Cold

water fill could expand and damage cast

iron, resulting in severe personal injury,

death or substantial property damage.

3. Check for maintained gauge pressure for more

than 10 minutes. Visually check for leaks if gauge

pressure drops.

4. Drain boiler. Repair leaks if found.

Do not use petroleum-based compounds

to repair leaks. Damage to system com-

ponents can result, causing property

damage.

5. Re-test boiler after repairing leaks.

6. Remove pressure gauge, air vent and plugs from

tappings used for controls.

7. Visually check:

a. Sealing rope placement

b. Metal-to-metal contact around port openings.

c. Flue collector hood seal.

d. Burner mounting door seal.

Obtain gas-tight seal to prevent possible

flue gas leakage and carbon monoxide

emissions, which can lead to severe per-

sonal injury or death.

Table 3 Control tappings (see Figure 7, page 17 for locations)

Install jacket

(Knocked-down boilers only)

Before installing jacket, remove burner mounting door.

See jacket instructions for details.

Install boiler controls

See control tapping location, Figure 7, control tappings,

Table 3, and Figure 8 or Figure 9 on page 17 to install

controls.

1. Do not use Teflon tape to install probe-type low

water cutoff; it will cause low water cutoff to work

improperly.

2. Install tankless heater control if tankless heater is

used. If not furnished, use operating control with

maximum 10°F differential.

3. Make sure gauge glass is last control installed to

prevent breakage.

4. Affix Consumer Protection (CP) number label(s)

on jacket front panel.

Install boiler –

Semi-packaged and Knocked-down boilers only (continued)

Loading ...

Loading ...

Loading ...