Loading ...

Loading ...

Loading ...

ADJUST PILOT BURNER

Pilot flame should surround 3/8' to 1/2" of the pilot sensor.

Refer to Fig. 19. If flame needs adjusting, do it as follows:

1. Remove screw cover over pilot adjusting screw.

2. Insert small screwdriver and adjust flame as needed. Turn

screw counterclockwise to increase flame, clockwise to

decrease.

3. Replace screw cover over pilot adjusting screw.

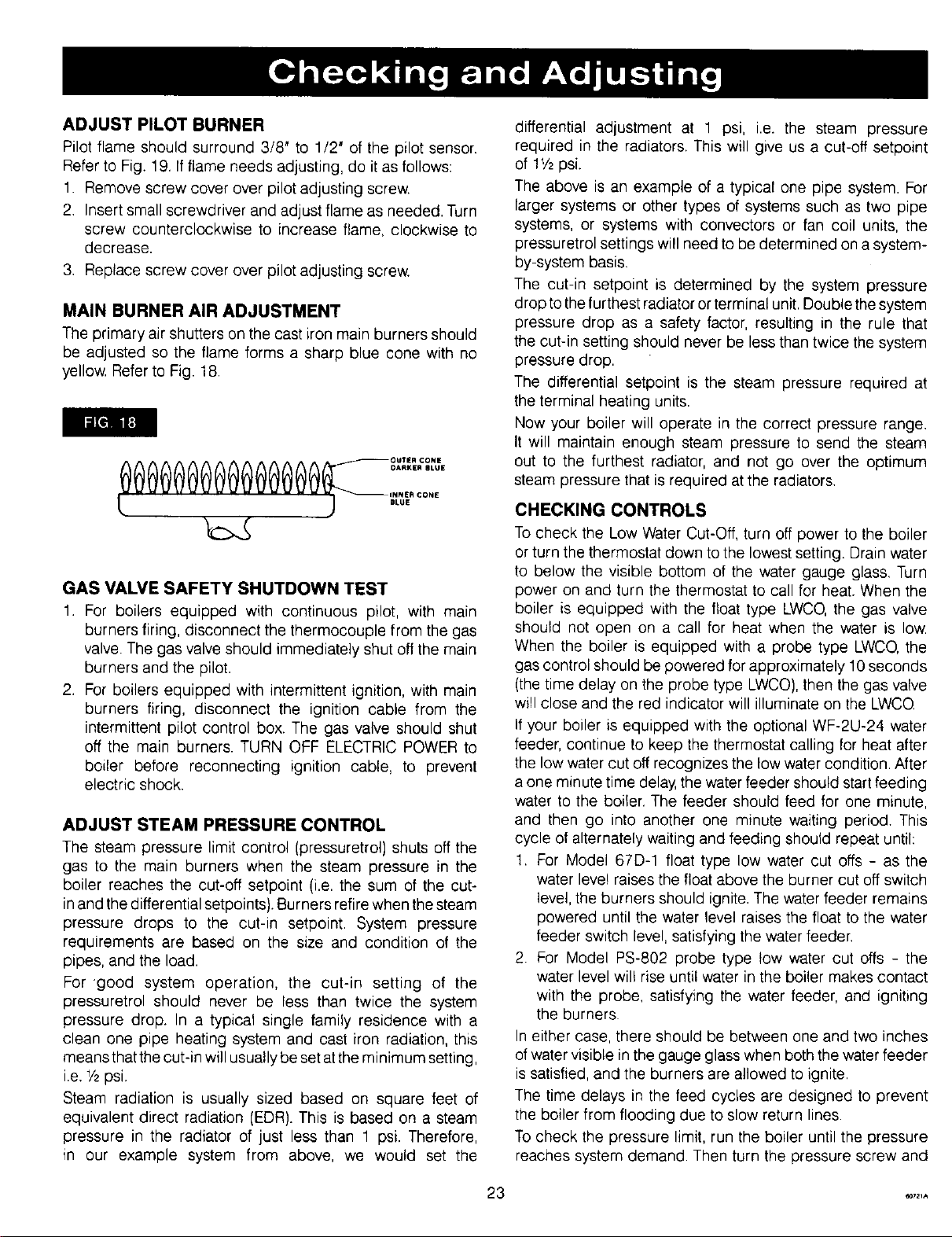

MAIN BURNER AIR ADJUSTMENT

The primary air shutters on the cast iron main burners should

be adjusted so the flame forms a sharp blue cone with no

yellow. Refer to Fig. 18.

li_[_ll i1I:]

0000@@0@0000 °°'''°°''

I_ARKIER BLUE

INNER CONE

t ) .Lo.

GAS VALVE SAFETY SHUTDOWN TEST

1. For boilers equipped with continuous pilot, with main

burners firing, disconnect the thermocouple from the gas

valve. The gas valve should immediately shut off the main

burners and the pilot.

2. For boilers equipped with intermittent ignition, with main

burners firing, disconnect the ignition cable from the

intermittent pilot control box. The gas valve should shut

off the main burners. TURN OFF ELECTRIC POWER to

boiler before reconnecting ignition cable, to prevent

electric shock.

ADJUST STEAM PRESSURE CONTROL

The steam pressure limit control (pressuretrol) shuts off the

gas to the main burners when the steam pressure in the

boiler reaches the cut-off setpoint (i.e. the sum of the cut-

in and the differential setpoints). Burners retire when the steam

pressure drops to the cut-in setpoint. System pressure

requirements are based on the size and condition of the

pipes, and the load.

For 'good system operation, the cut-in setting of the

pressuretrol should never be less than twice the system

pressure drop. In a typical single family residence with a

clean one pipe heating system and cast iron radiation, this

means that the cut-in will usually be set atthe minimum setting,

i.e. 1/2psi.

Steam radiation is usually sized based on square feet of

equivalent direct radiation (EDR). This is based on a steam

pressure in the radiator of just less than 1 psi. Therefore,

in our example system from above, we would set the

differential adjustment at 1 psi, i.e. the steam pressure

required in the radiators. This will give us a cut-off setpoint

of 11/2psi.

The above is an example of a typical one pipe system. For

larger systems or other types of systems such as two pipe

systems, or systems with convectors or fan coil units, the

pressuretrol settings will need to be determined on a system-

by-system basis.

The cut-in setpoint is determined by the system pressure

drop tothe furthest radiator or terminal unit. Double the system

pressure drop as a safety factor, resulting in the rule that

the cut-in setting should never be less than twice the system

pressure drop.

The differential setpoint is the steam pressure required at

the terminal heating units.

Now your boiler will operate in the correct pressure range.

It will maintain enough steam pressure to send the steam

out to the furthest radiator, and not go over the optimum

steam pressure that is required at the radiators.

CHECKING CONTROLS

To check the Low Water Cut-Off, turn off power to the boiler

or turn the thermostat down to the lowest setting. Drain water

to below the visible bottom of the water gauge glass. Turn

power on and turn the thermostat to call for heat. When the

boiler is equipped with the float type LWCO, the gas valve

should not open on a call for heat when the water is low.

When the boiler is equipped with a probe type LWCO, the

gas control should be powered for approximately 10 seconds

(the time delay on the probe type LWCO), then the gas valve

will close and the red indicator will illuminate on the LWCQ

If your boiler is equipped with the optional WF-2U-24 water

feeder, continue to keep the thermostat calling for heat after

the low water cut off recognizes the low water condition. After

a one minute time delay, the water feeder should start feeding

water to the boiler, The feeder should feed for one minute,

and then go into another one minute waiting period. This

cycle of alternately waiting and feeding should repeat until:

1. For Model 67D-1 float type low water cut offs - as the

water leve! raises the float above the burner cut off switch

level, the burners should ignite. The water feeder remains

powered until the water level raises the float to the water

feeder switch level, satisfying the water feeder,

2. For Model PS-802 probe type tow water cut offs - the

water level wil! rise until water in the boiler makes contact

with the probe, satisfying the water feeder, and igniting

the burners

In either case, there should be between one and two inches

of water visible in the gauge glass when both the water feeder

is satisfied, and the burners are allowed to ignite.

The time delays in the feed cycles are designed to prevent

the boiler from flooding due to slow return lines.

To check the pressure limit, run the boiler until the pressure

reaches system demand. Then turn the pressure screw and

3 _21A

Loading ...

Loading ...

Loading ...