Loading ...

Loading ...

Loading ...

CATALYTIC COMBUSTORS

Here is how your catalytic combustor works.

The catalytic combustor is a stainless steel foil with hundreds of cells. Precious metals,

such as platinum, are sprayed on the inside of these cells to coat the steel foil. This

creates the surface area which interacts with the wood smoke. The catalytic combustor in

your stove is very similar to the one in the exhaust system of your automobile and works

to achieve the same results - high efficiency and clean air!

When you first start a fire, you should bypass your catalytic combustor and let the smoke go directly up the chimney.

Once wood smoke reaches 500º F internally (about 10-15 minutes after re-establishing a strong fire), it is hot enough to

ignite the catalytic combustor. As the wood smoke passes through the cells in the combustor, the smoke reacts with the

precious metals which line the inside of the honeycomb and both combustible gases and particles in the smoke ignite

and burn. This “catalytic burn” reduces emissions and also increases heat output from the stove.

Without a catalytic combustor, between 5% - 40% of the chemical energy contained in wood simply escapes up the

chimney when wood is burned. Energy laden gases are exhausted up the chimney where they pollute the air or may

condense on the inside of the chimney flue as creosote. The slower the burn, without a catalytic combustor, the greater

the amount of energy that is lost. A long smoldering fire is the least efficient use of energy in wood, yet it produces lots

of smoke, which is the fuel supply for the catalytic combustor.

Most of the chemical compounds in wood smoke are combustible. The catalyst produces

high temperatures, which loosen the bonds of these chemical compounds and “burns” wood

smoke. A stove that “burns” these compounds and uses smoke as additional fuel will burn

more efficiently and produce more heat, while reducing creosote and air pollution at the same

time. However, most stoves cannot consistently produce temperatures high enough to burn

cleanly, particularly during long burning times - hence the need for a catalytic combustor.

Your catalytic combustor can get the most efficiency out of every piece of wood if it has

three things: temperature, turbulence, and time.

1. Temperature. The catalytic combustor can only start burning the gases in the wood smoke

after the smoke has reached at least 500 degrees F. Before the smoke reaches that

temperature, it simply is not hot enough to start the reaction at the combustor. This will

result in an inefficient smoldering fire.

2. Turbulence. The wood smoke can interact best with the precious metals inside the foil

cells if there is some variation in the air flow. Increased turbulence enables more of the

wood smoke to come into contact with more cells. The exhaust path as well as the irregular surface of the combustor

cells adds needed turbulence.

3. Time. Once the temperature and turbulence are achieved, the catalytic combustor just

needs to have enough time to burn all the gases in the wood smoke. For this reason, it is

best to minimize the amount of air you allow into the firebox once the combustor is

ignited. Allowing too much air into the firebox speeds up the rate at which the fire burns.

The ideal air setting for a long catalytic burn allows enough air to keep the wood burning

and producing smoke.

With proper care, a new catalytic combustor will give years of fuel savings and lowered

emissions. By following some simple guidelines you can ensure maximum combustor performance and longevity. Your

catalytic combustor is designed to last for 12,000 -14,000 hours of use. You can ensure yourself of getting the maximum

life from your combustor by following these simple guidelines:

1) Burn only natural, well-seasoned wood.

2) Wait until the exhaust gases reach about 500 degrees F (internally), equals 250° externally, before engaging the

catalytic combustor (about 10-15 minutes after re-establishing a strong fire).

3) Bypass the combustor before reloading and leave the bypass open for a few minutes after reloading to raise

the temperature in the stove.

4) Don’t overfire the stove.

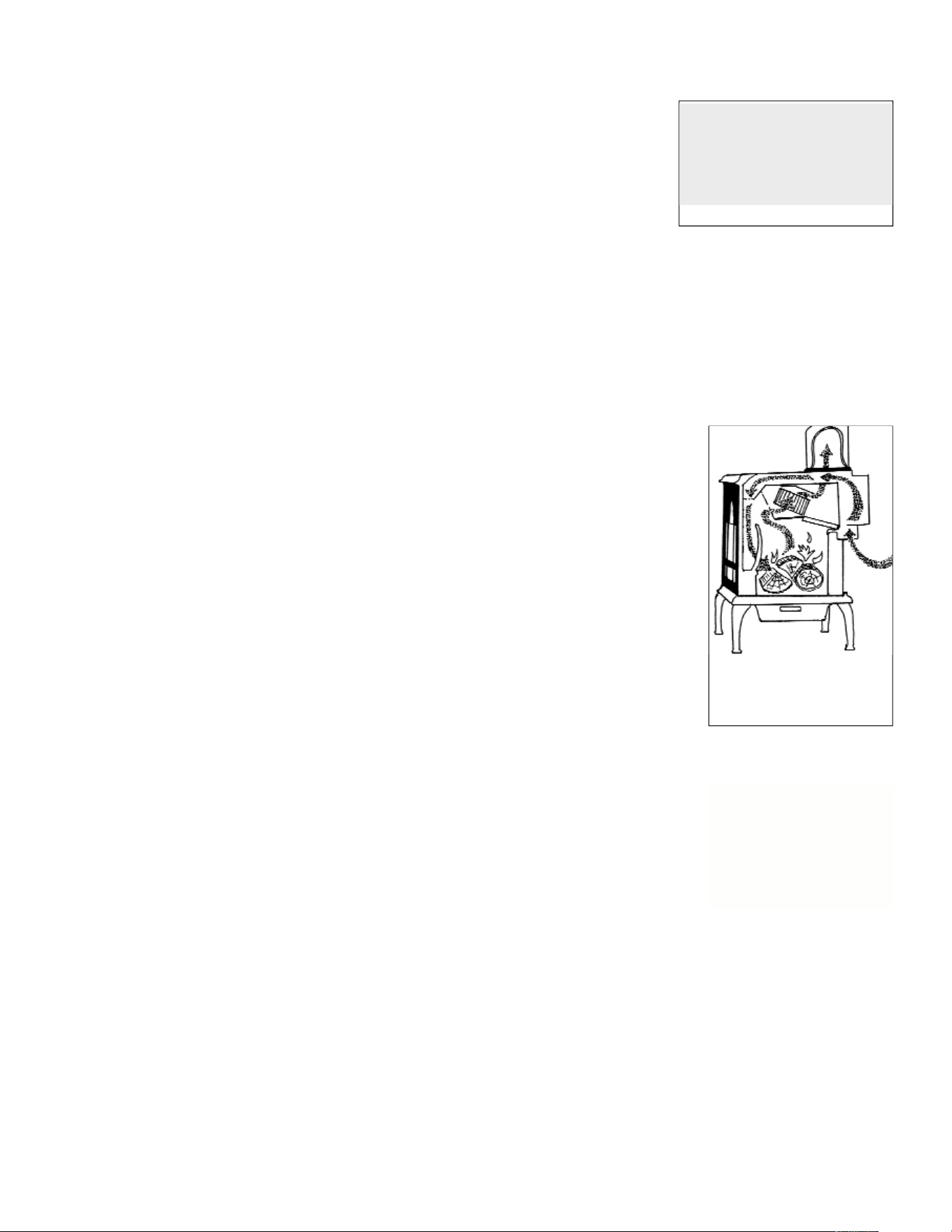

Cut-away drawing of the airflow

pattern. Air enters the firebox by

washing down over the window

and exits after going through the

combustor.

Stainless Steel Foil Catalytic Combustor

within a steel frame.

17

Loading ...

Loading ...

Loading ...