Loading ...

Loading ...

Loading ...

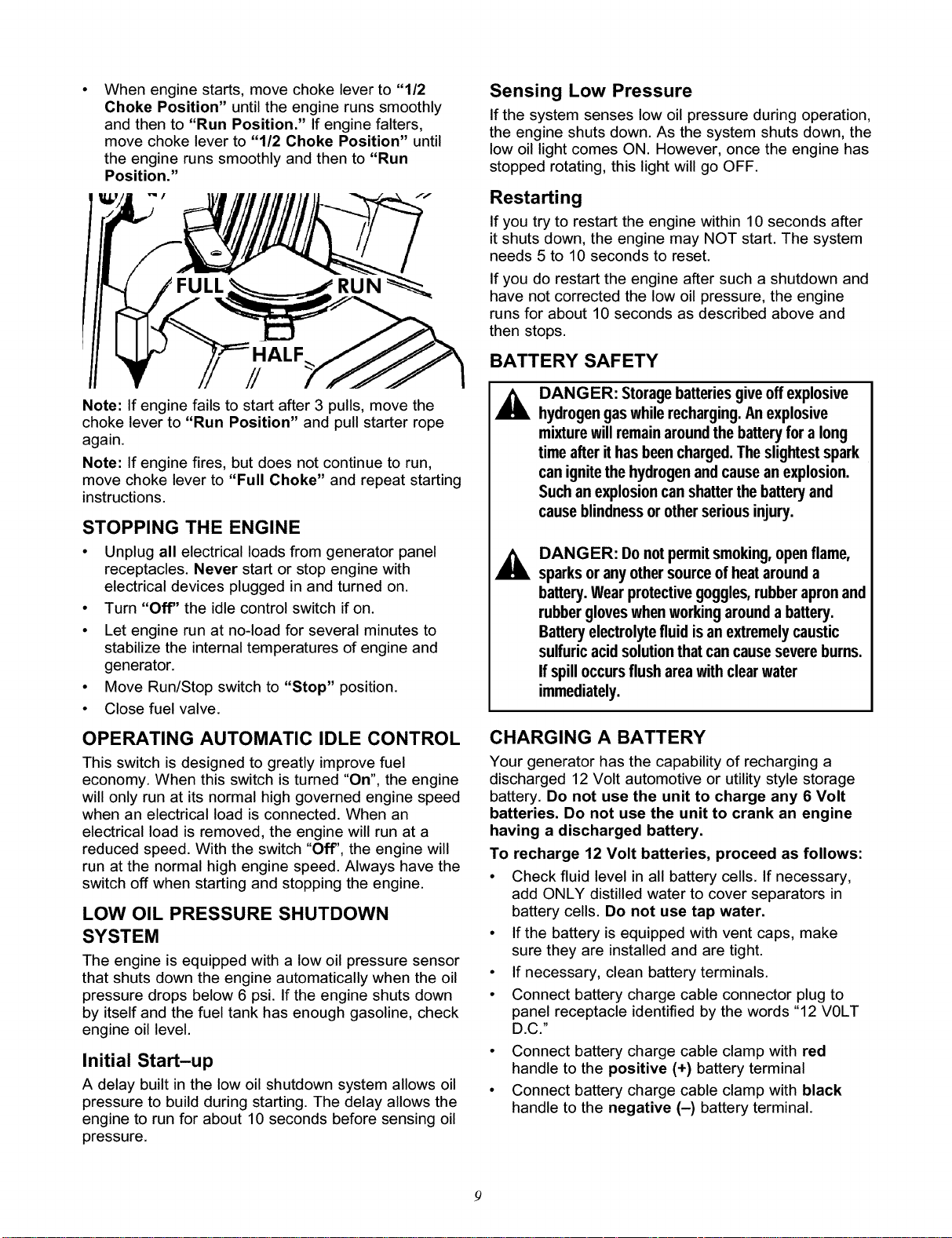

Whenenginestarts,movechokeleverto"1/2

ChokePosition"untiltheenginerunssmoothly

andthento"RunPosition."Ifenginefalters,

movechokeleverto"1/2ChokePosition"until

theenginerunssmoothlyandthento"Run

Position."

FULL RUN

HALF

//

Note: If engine fails to start after 3 pulls, move the

choke lever to "Run Position" and pull starter rope

again.

Note: If engine fires, but does not continue to run,

move choke lever to "Full Choke" and repeat starting

instructions.

STOPPING THE ENGINE

• Unplug all electrical loads from generator panel

receptacles. Never start or stop engine with

electrical devices plugged in and turned on.

• Turn "Off" the idle control switch if on.

• Let engine run at no-load for several minutes to

stabilize the internal temperatures of engine and

generator.

• Move Run/Stop switch to "Stop" position.

• Close fuel valve.

OPERATING AUTOMATIC IDLE CONTROL

This switch is designed to greatly improve fuel

economy. When this switch is turned "On", the engine

will only run at its normal high governed engine speed

when an electrical load is connected. When an

electrical load is removed, the engine will run at a

reduced speed. With the switch "Off", the engine will

run at the normal high engine speed. Always have the

switch off when starting and stopping the engine.

LOW OIL PRESSURE SHUTDOWN

SYSTEM

The engine is equipped with a low oil pressure sensor

that shuts down the engine automatically when the oil

pressure drops below 6 psi. If the engine shuts down

by itself and the fuel tank has enough gasoline, check

engine oil level.

Initial Start-up

A delay built in the low oil shutdown system allows oil

pressure to build during starting. The delay allows the

engine to run for about 10 seconds before sensing oil

pressure.

Sensing Low Pressure

If the system senses low oil pressure during operation,

the engine shuts down. As the system shuts down, the

low oil light comes ON. However, once the engine has

stopped rotating, this light will go OFF.

Restarting

If you try to restart the engine within 10 seconds after

it shuts down, the engine may NOT start. The system

needs 5 to 10 seconds to reset.

If you do restart the engine after such a shutdown and

have not corrected the low oil pressure, the engine

runs for about 10 seconds as described above and

then stops.

BATTERY SAFETY

DANGER: Storagebatteriesgive offexplosive

hydrogengas while recharging.Anexplosive

mixturewill remainaroundthe batteryfor a long

timeafterit hasbeencharged.The slightestspark

canignitethe hydrogenand causean explosion.

Suchan explosioncanshatterthe batteryand

causeblindnessor otherseriousinjury.

DANGER: Donotpermitsmoking,openflame,

sparksoranyothersourceofheatarounda

battery.Wearprotectivegoggles,rubberapronand

rubbergloveswhenworkingaroundabattery.

Batteryelectrolytefluid isanextremelycaustic

sulfuricacidsolutionthatcancausesevereburns.

Ifspilloccursflushareawithclearwater

immediately.

CHARGING A BATTERY

Your generator has the capability of recharging a

discharged 12 Volt automotive or utility style storage

battery. Do not use the unit to charge any 6 Volt

batteries. Do not use the unit to crank an engine

having a discharged battery.

To recharge 12 Volt batteries, proceed as follows:

• Check fluid level in all battery cells. If necessary,

add ONLY distilled water to cover separators in

battery cells. Do not use tap water.

• If the battery is equipped with vent caps, make

sure they are installed and are tight.

• If necessary, clean battery terminals.

• Connect battery charge cable connector plug to

panel receptacle identified by the words "12 VOLT

D.C."

• Connect battery charge cable clamp with red

handle to the positive (+) battery terminal

• Connect battery charge cable clamp with black

handle to the negative (-) battery terminal.

Loading ...

Loading ...

Loading ...