Loading ...

Loading ...

Loading ...

To clean or replace foam pre-cleaner:

• Remove air cleaner cover, then foam pre-filter.

• Wash pre-cleaner in soapy water. Squeeze pre-

filter dry in clean cloth (DO NOT TWIST).

• Clean air cleaner cover before installing it.

To clean or replace paper air filter:

• Remove air cleaner cover; then remove foam pre-

filter (service if necessary) and remove paper filter.

• Clean paper filter by tapping it gently on a solid

surface. If the filter istoo dirty, replace it with a new

one. Dispose of the old filter properly.

• Clean air cleaner cover then insert pre-cleaner into

cover. Next insert new paper filter into cover to hold

pre-cleaner in place and assemble all of them to

the base of the air cleaner.

Note: If you need to order a new air filter, please call

1-800-366-PART.

CLEAN SPARK ARRESTOR SCREEN

The engine exhaust muffler has a spark arrestor

screen. Inspect and clean the screen every 100 hours

of operation or once each year, whichever comes first.

NOTE: If you use your generator on any forest-

covered, brush-covered or grass-covered unimproved

land, it must have a spark arrestor. The spark arrestor

must be maintained in good condition by the

owner/operator.

Clean and inspect the spark arrestor as follows:

• To remove the muffler guard from the muffler,

remove the four screws that connect the guard to

the muffler bracket.

SPARKARRESTER

SCREEN

MUFFLER

HEAT SHIELD

To adjusting valve clearance:

• Make sure the engine is at room temperature

• Make sure that the spark plug wire is removed from

the spark plug and out of the way.

Remove the breather tube from the valve cover.

Remove the four screws attaching the valve cover

with a #2 or 3 phillips screwdriver.

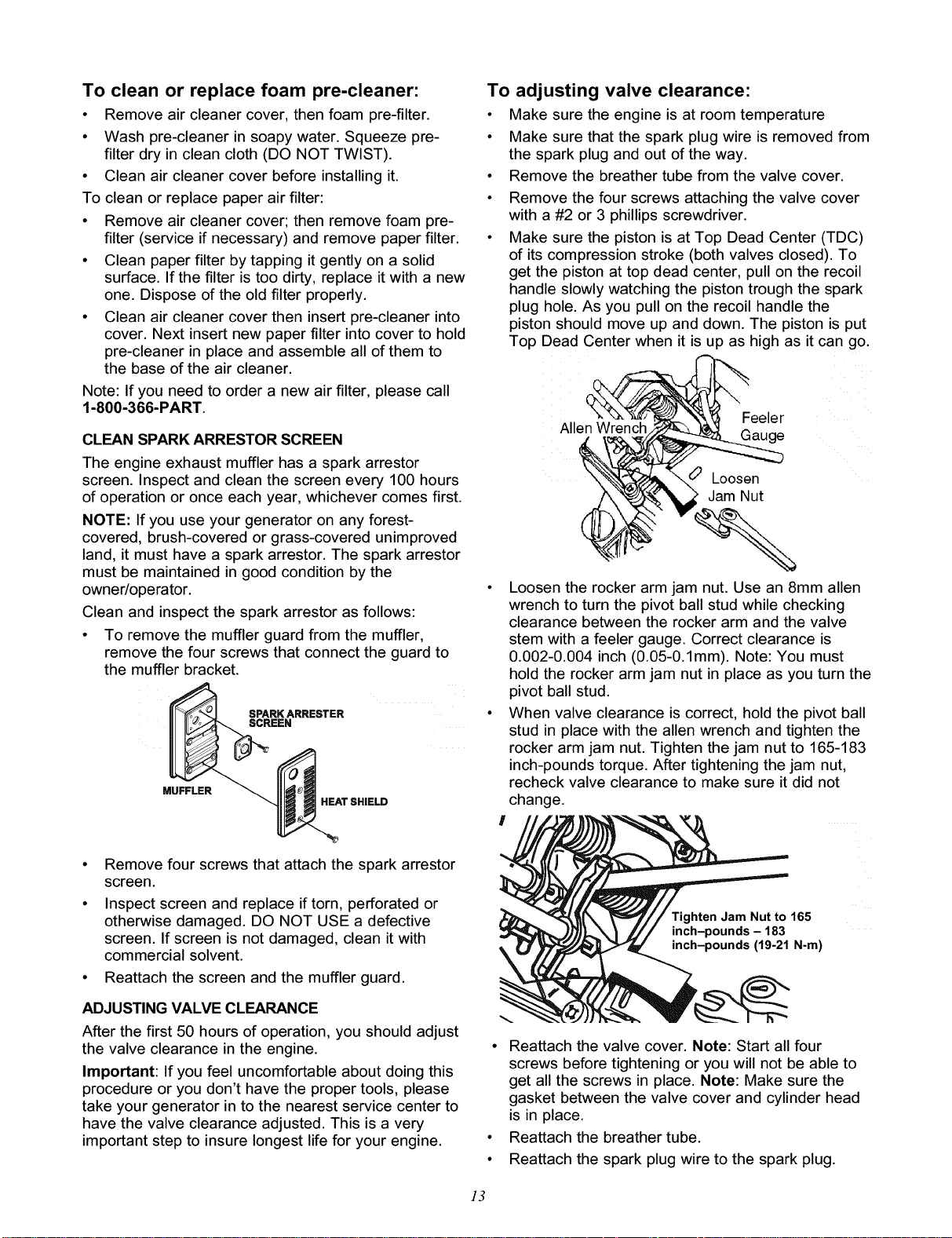

Make sure the piston is at Top Dead Center (TDC)

of its compression stroke (both valves closed). To

get the piston at top dead center, pull on the recoil

handle slowly watching the piston trough the spark

plug hole. As you pull on the recoil handle the

piston should move up and down. The piston is put

Top Dead Center when it is up as high as it can go.

Feeler

Allen Wrench Gauge

Loosen

Jam Nut

• Loosen the rocker arm jam nut. Use an 8mm allen

wrench to turn the pivot ball stud while checking

clearance between the rocker arm and the valve

stem with a feeler gauge. Correct clearance is

0.002-0.004 inch (0.05-0.1mm). Note: You must

hold the rocker arm jam nut in place as you turn the

pivot ball stud.

• When valve clearance is correct, hold the pivot ball

stud in place with the allen wrench and tighten the

rocker arm jam nut. Tighten the jam nut to 165-183

inch-pounds torque. After tightening the jam nut,

recheck valve clearance to make sure it did not

change.

Remove four screws that attach the spark arrestor

screen.

Inspect screen and replace if torn, perforated or

otherwise damaged. DO NOT USE a defective

screen. If screen is not damaged, clean it with

commercial solvent.

Reattach the screen and the muffler guard.

ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, you should adjust

the valve clearance in the engine.

Important: If you feel uncomfortable about doing this

procedure or you don't have the proper tools, please

take your generator in to the nearest service center to

have the valve clearance adjusted. This is a very

important step to insure longest life for your engine.

Tighten Jam Nut to 165

inch-pounds - 183

inch-pounds (19-21 N-m)

Reattach the valve cover. Note: Start all four

screws before tightening or you will not be able to

get all the screws in place. Note: Make sure the

gasket between the valve cover and cylinder head

is in place.

Reattach the breather tube.

Reattach the spark plug wire to the spark plug.

/3

Loading ...

Loading ...

Loading ...