Loading ...

Loading ...

Loading ...

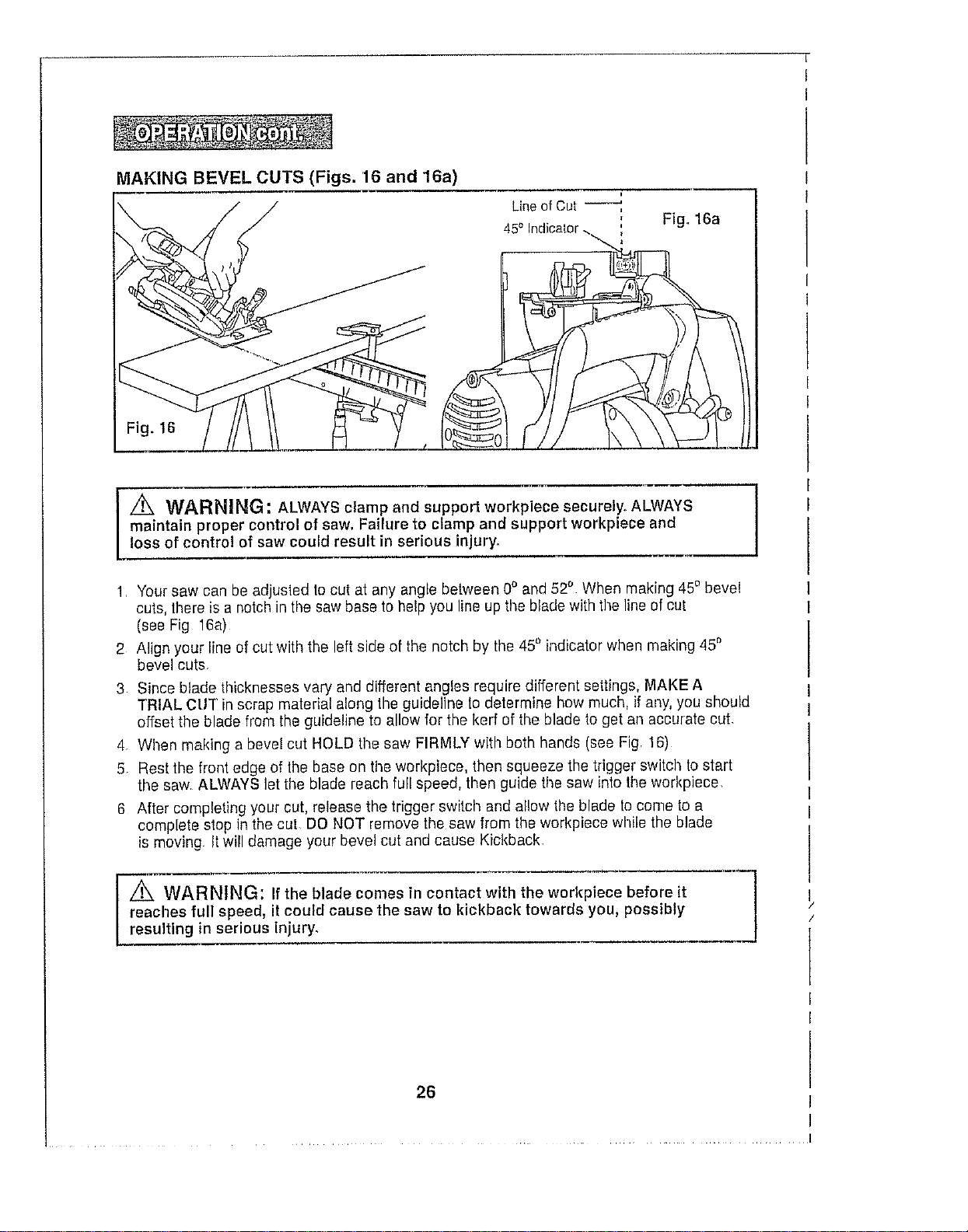

MAKING BEVEL CUTS (Figs. 16 and 16a)

t

Lineof Cut

45oIndicator Fig. 16a

Fig. 16

WARNING: ALWAYS clamp and support workpiece securely.. ALWAYS

maintain proper control of saw. Failure to clamp and support workpiece and

loss of control of saw could result in serious injury.

1, Your saw can be adjusled to cut at any angle between 0° and 520 When making 450 bevel

cuts, there is a notch in tile saw base to help you line up timeblade with timeline of cut

(see Fig 16a)

2 Align your line of cut with the left side of the notch by the 450 indicator when making 450

bevel cuts

3 Since blade thicknesses vary and different angles require different settings, MAKE A

TRIAL CUT in scrap material along the guideline to determine how much, if any, you should

offset the blade from the guideline to allow for the kerf of the blade to get an accurate cut.

4. When making a bevel cut HOLD the saw FIRMLY with both hands (see Fig, 16)

5 Rest the front edge of the base on timeworkpiece, then squeeze the trigger switch to start

the saw. ALWAYS let the blade reach full speed, then guide timesaw into the workpiece.

6 After completing your cut, release the trigger switch and allow the blade to come to a

complete stop in the cut. DO NOT remove the saw from the werkpiece while the blade

is moving Itwill damage your bevel cut and cause Kickback.

WARNING: If the blade comes in contact with the workpiece before it

reaches full speed, it could cause the saw to kickback towards you, possibly

resulting in serious injury.

26

Loading ...

Loading ...

Loading ...