Loading ...

Loading ...

Loading ...

MAKING RIP CUTS

ALWAYS use a guide when making long or wide rip cuts with your saw, You can use

either a straight edge or use the edge guide that was included with your saw,

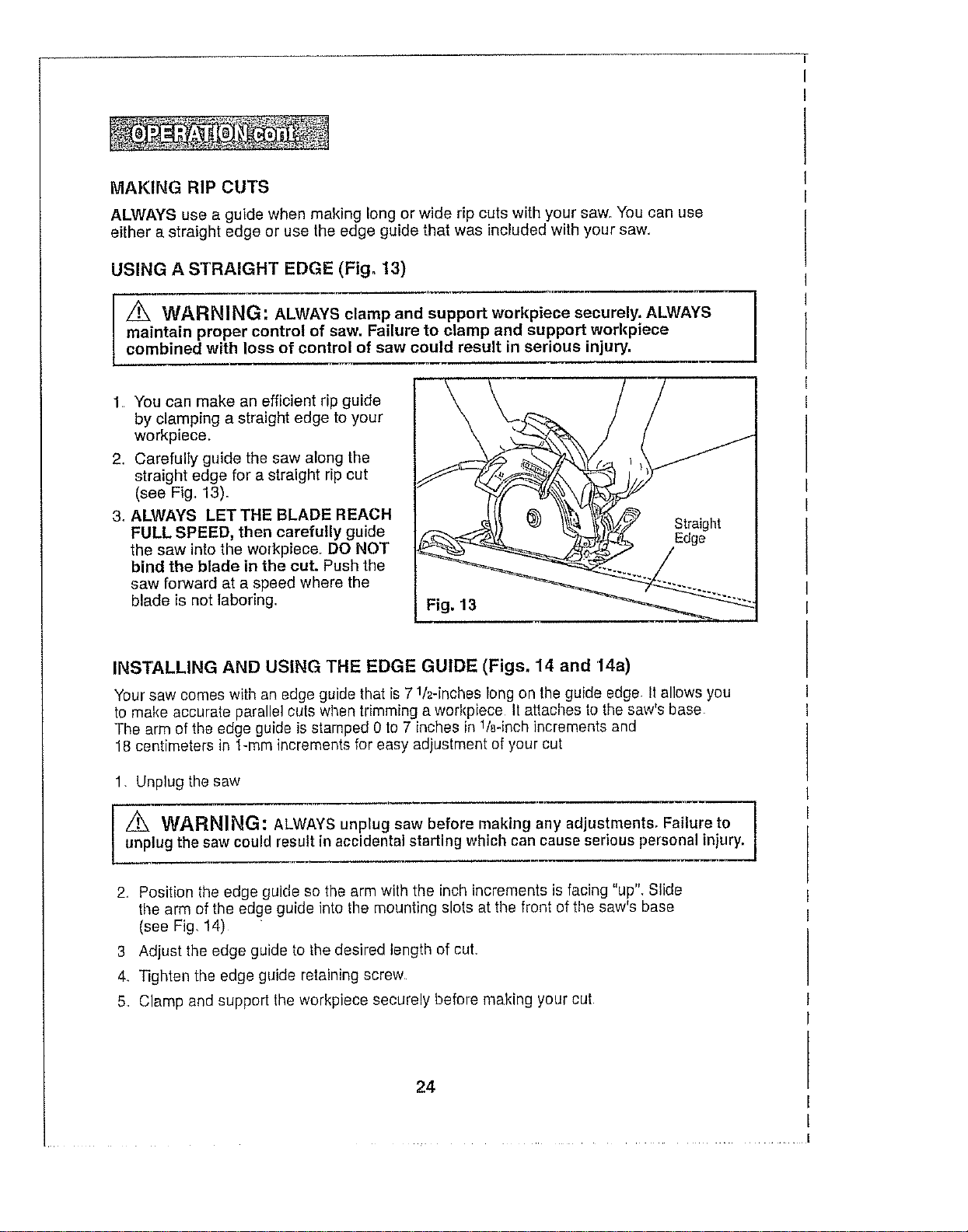

USING A STRAIGHT EDGE (Fig. 13)

/_ WARNI NG: ALWAYS clamp and support workpiece securely. ALWAYS

maintain proper control of saw. Failure to clamp and su.pport workpiece

combined with loss of control of saw could result in serious injury.

1.. You can make an efficient rip guide

by clamping a straight edge to your

workpiece.

2.. Carefully guide the saw along the

straight edge for a straight rip cut

(see Fig. 13).

3. ALWAYS LET THE BLADE REACH

FULL SPEED, then carefully guide

the saw into the workpiece. DO NOT

bind the blade in the cut. Push the

saw forward at a speed where the

blade is not laboring.

Fig. 13

Straight

Edge

INSTALLING AND USING THE EDGE GUIDE (Figs. 14 and 14a)

Your saw comes with an edge guide that is 7 1/2-inches long on the guide edge !t allows you

to make accurate parallel cuts when trimming a workpiece It attaches to the saw's base

The arm of the edge guide is stamped 0 to 7 inches in l/B-inch increments and

18 centimeters in l-ram increments for easy adjustment of your cut

1. Unplug the saw

Z_ WARNING: ALWAYS unplug saw before making any adjustments. Failure to

unplug the saw could result in accidental starting which can cause serious personal injury.

2_

3

4_

Position the edge guide so the arm with the inch increments is facing "up". Slide

the arm of the edge guide into the mounting slots at the front of the saw's base

(see Fig. 14)

Adjust the edge guide to tile desired length of cut

Tighten the edge guide retaining screw

Clamp and support the workpiece securely before making your cut

24

Loading ...

Loading ...

Loading ...