Loading ...

Loading ...

Loading ...

• Make sure abrasive belt always tracks properly. Correct

tracking gives optimum performance.

• After turning switch on, always allow belt and disc to come

up to full speed before sanding or grinding.

• Be sure disc turns counterclockwise. Abrasive belt must

travel downward.

• Avoid kickback by sanding in accordance with the direction-

al arrows.

• Keep your hands clear of abrasive belt, disc and all moving

parts.

• For optimum performance, do not stall motor or reduce

speed. Do not force the work into the abrasive.

• Always support workpiece with table or work stop when

sanding with belt and with table when sanding with disc.

• Never push a sharp corner of the workpiece rapidly against

the belt or disc. Abrasive backing may tear.

• Replace abrasives when they become loaded (glazed) or

frayed.

ON/OFF SWITCH

Refer to Figure 7.

The ON/OFF switch is located on the upper front right of the

cabinet. To turn the sander ON, pull the switch to the up

position. To turn the sander OFF, push the switch to the down

position.

The sander can be locked from unauthorized use by locking

the switch. To lock the switch:

= Turn the switch to OFF position and disconnect sander

from power source.

= Pull the key out. The switch cannot be turned on with the

key removed.

NOTE: Should the key be removed from the switch at the ON

position, the switch can be turned off but cannot be turned on

again.

= To replace key, slide key into the slot on switch until it snaps.

Figure 7 - Locking Switch in OFF Position

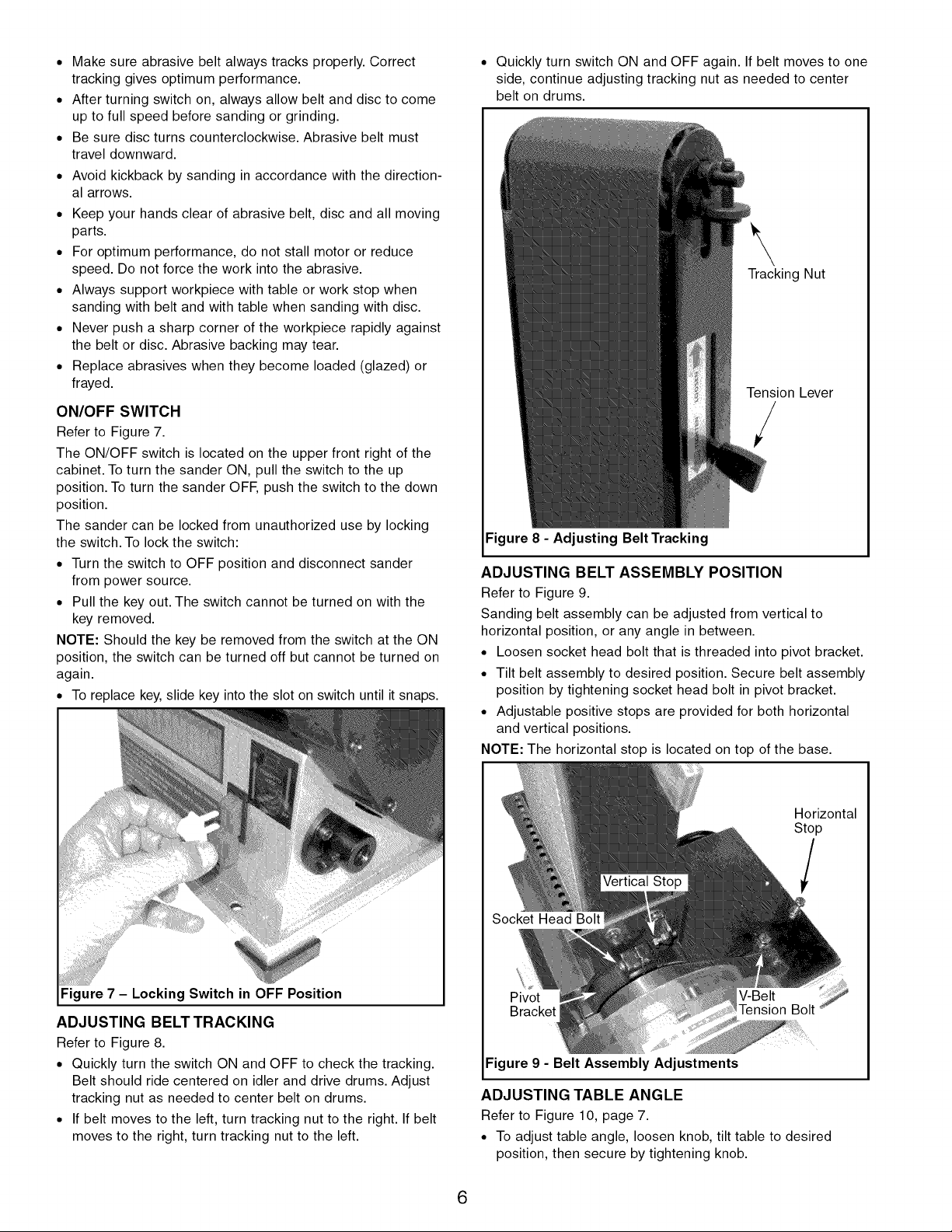

ADJUSTING BELT TRACKING

Refer to Figure 8.

° Quickly turn the switch ON and OFF to check the tracking.

Belt should ride centered on idler and drive drums. Adjust

tracking nut as needed to center belt on drums.

• If belt moves to the left, turn tracking nut to the right. If belt

moves to the right, turn tracking nut to the left.

• Quickly turn switch ON and OFF again. If belt moves to one

side, continue adjusting tracking nut as needed to center

belt on drums.

\

Tracking Nut

Tension Lever

/

Figure 8 - Adjusting Belt Tracking

ADJUSTING BELT ASSEMBLY POSITION

Refer to Figure 9.

Sanding belt assembly can be adjusted from vertical to

horizontal position, or any angle in between.

• Loosen socket head bolt that is threaded into pivot bracket.

• Tilt belt assembly to desired position. Secure belt assembly

position by tightening socket head bolt in pivot bracket.

• Adjustable positive stops are provided for both horizontal

and vertical positions.

NOTE: The horizontal stop is located on top of the base.

Horizontal

Stop

Pivot

Figure 9 - Belt Assembly Adjustments

ADJUSTING TABLE ANGLE

Refer to Figure 10, page 7.

• To adjust table angle, loosen knob, tilt table to desired

position, then secure by tightening knob.

6

Loading ...

Loading ...

Loading ...