Loading ...

Loading ...

Loading ...

Part number 550-100-325/0419

119

AquaBalance

®

Series 2 Wall Mount Gas-fired Water Boiler – Boiler Manual

38 Maintenance (continued)

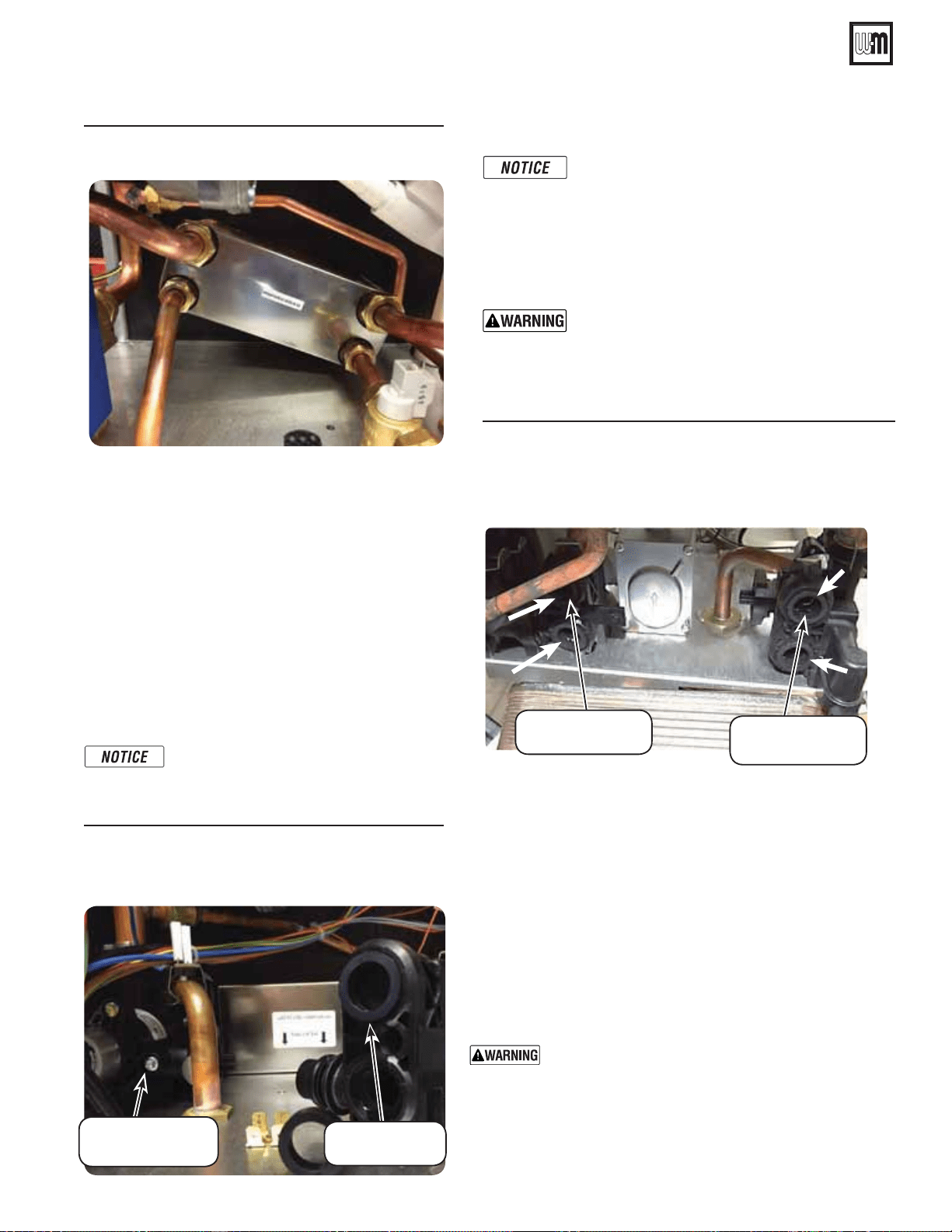

DHW Outlet

(diverter valve)

DHW Inlet

5. The treatment time must be chosen according to the

amount of scale deposits present in the exchanger and

however such time must always be less than the maxi-

mum treatment time specified by the manufacturer on

the product data sheet.

6. At the end of the cleaning cycle recover the chemical

product in appropriate containers for disposal.

7. Perform a washing bath with potable water in order

to remove the chemical product still present within

the coils of the heat exchanger, recovering the liquid in

suitable containers for disposal.

8. Repeat the washing with water more than once if neces-

sary.

9. The cleaned brazed plate heat exchanger can now be

installed.

e brazed plate heat exchanger must be

reinstalled in the same orientation.

e direction of arrows on heat exchanger.

Figure 160

Figure 161

Figure 162

Combi 80/120 flat plate heat exchanger

reinstalled

e four (4) new gaskets must be placed in the

DHW inlet and DHW return plate connections to

seal brazed plate heat exchanger.

1. Slide the brazed plate heat exchanger into rear of enclosure

(orientation arrows pointing down).

2. Lift brazed plate heat exchanger slightly up and align with DHW

connections, reinstall the two (2) Phillips head screws, tighten

securely. (Torque to 3.3 lb-ft. +/- 0.37 lb-ft.)

When re-installing components, make sure gas-

kets are in good condition and properly aligned

before tightening screws.

3. Be sure the pressure relief (plastic) screw has been made tight,

Location(6), see Figure 156.

Combi 155 flat plate heat exchanger reinstalled

1. For the Combi-155, slide the cleaned brazed plate heat exchanger

into rear of enclosure (orientation as shown in Figure160).

2. Lift brazed plate heat exchanger slightly up and align with DHW

connections, reinstall the fittings. e four (4) gaskets must be

placed in the DHW inlet and DHW return plate connections to

seal brazed plate heat exchanger.

1. Reassemble boiler components check seals for any leaks.

2. Open the valve of cold water inlet placed before the boiler inlet.

Run water until all air is purged from both the brazed plate heat

exchanger and the primary heat exchanger.

3. At initial fill and during boiler startup and testing, check system

thoroughly for any leaks. Repair all leaks before proceeding further.

Eliminate all system leaks. Continual fresh make up

water will reduce boiler life. Minerals can build up in the

heat exchanger, reducing heat transfer, overheating heat

exchanger, and causing heat exchanger failure.

4. Reconnect the unit to the electrical power supply using the switch

and/or the special cut-off devices and turn it ON.

5. Check the correct operation of the boiler and functionality of

production of domestic hot water.

DHW returns

(diverter valve)

DHW inlet

Loading ...

Loading ...

Loading ...