Loading ...

Loading ...

Loading ...

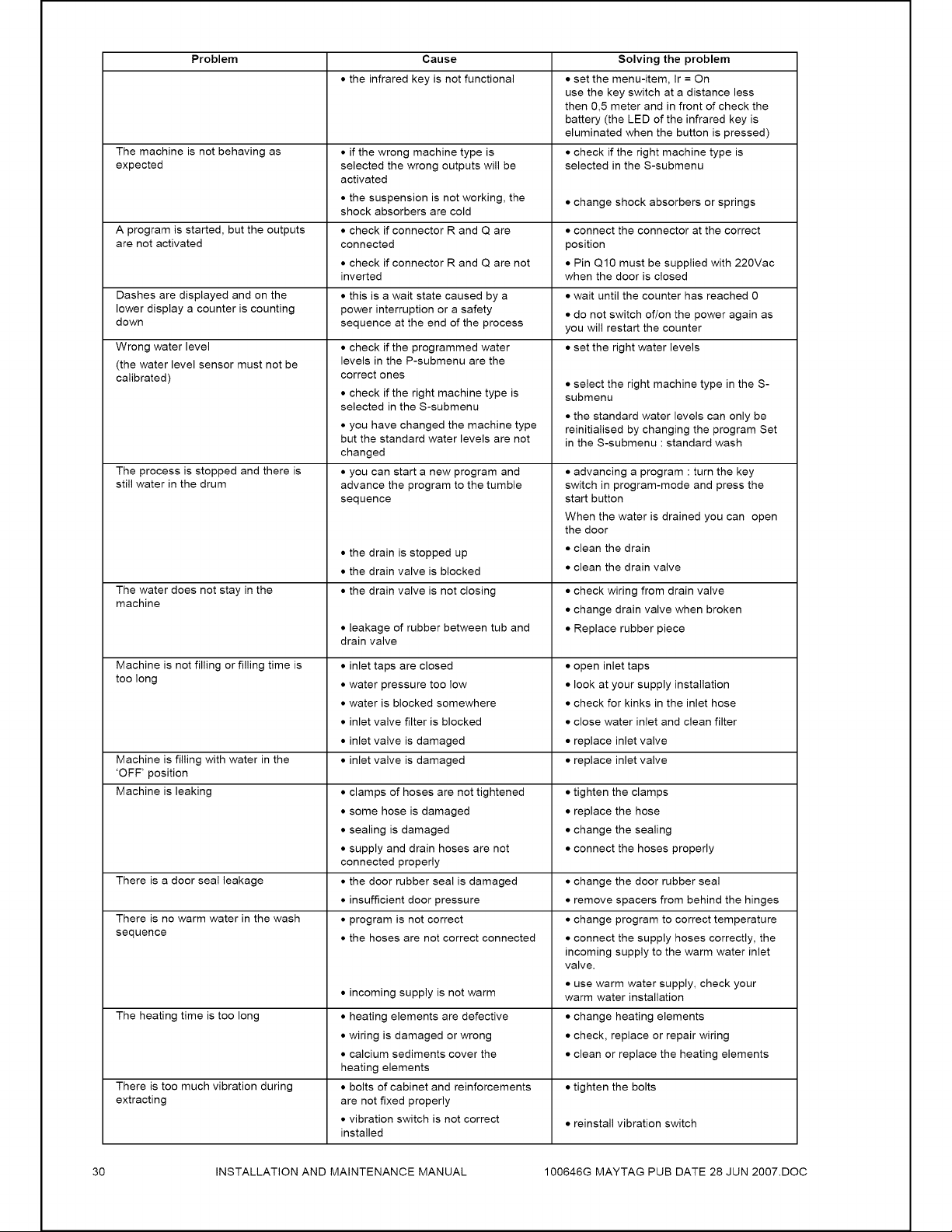

Problem

Cause

Solving

the

problem

«

the

infrared

key

is

not

functional

eset

the

menu-item,

Ir

=

On

use

the

key

switch

at

a

distance

less

then

0,5

meter

and

in

front

of

check

the

battery

(the

LED

of

the

infrared

key

is

eluminated

when

the

button

is

pressed)

The

machine

is

not

behaving

as

expected

if

the

wrong

machine

type

is

selected

the

wrong

outputs

will

be

activated

«

the

suspension

is

not

working,

the

shock

absorbers

are

cold

«

check

if

the

right

machine

type

is

selected

in

the

S-submenu

«

change

shock

absorbers

or

springs

A

program

is

started,

but the

outputs

are

not

activated

«

check

if

connector

R

and

Q

are

connected

«

check

if

connector

R

and

Q

are

not

inverted

«

connect

the

connector

at

the

correct

position

¢

Pin

Q10

must

be

supplied

with

220Vac

when

the

door

is

closed

Dashes

are

displayed

and

on

the

lower

display

a

counter

is

counting

down

«

this

is

a

wait

state

caused

by

a

power

interruption

or

a

safety

sequence

at

the

end

of

the

process

¢

wait

until

the

counter

has

reached

0

¢

do

not

switch

of/on

the

power

again

as

you

will

restart

the

counter

Wrong

water

level

(the

water

level

sensor

must

not

be

calibrated)

«

check

if

the

programmed

water

levels

in

the

P-submenu

are

the

correct

ones

«

check

if

the

right

machine

type

is

selected

in

the

S-submenu

*

you

have

changed

the

machine

type

but

the

standard

water

levels

are

not

changed

¢

set

the

right

water

levels

«

select

the

right

machine

type

in

the

S-

submenu

¢

the

standard

water

levels

can

only

be

reinitialised

by

changing

the

program

Set

in

the

S-submenu

:

standard

wash

The

process

is

stopped

and

there

is

still

water

in

the

drum

*

you

can

start

a

new program

and

advance

the

program

to

the

tumble

sequence

«

the

drain

is

stopped

up

«

the

drain

valve

is

blocked

¢

advancing

a

program

:

turn

the

key

switch

in

program-mode

and

press

the

start

button

When

the

water

is

drained

you can

open

the

door

e

clean

the

drain

e

clean

the

drain

valve

The

water

does

not

stay

in

the

machine

«

the

drain

valve

is

not

closing

«

leakage

of

rubber

between

tub

and

drain

valve

«

check

wiring

from

drain

valve

¢

change

drain

valve

when

broken

«

Replace

rubber

piece

Machine

is

not

filling

or

filling

time

is

too

long

«

inlet

taps

are

closed

«

water

pressure

too

low

¢

water

is

blocked

somewhere

e

inlet

valve

filter

is

blocked

e

inlet

valve

is

damaged

¢

open

inlet

taps

¢

look

at

your

supply

installation

¢

check

for

kinks

in

the

inlet

hose

¢

close

water

inlet

and

clean

filter

¢

replace

inlet

valve

Machine

is

filling

with

water

in

the

‘OFF’

position

e

inlet

valve

is

damaged

¢

replace

inlet

valve

Machine

is

leaking

«

clamps

of

hoses

are

not

tightened

«some

hose

is

damaged

«

sealing

is

damaged

«

supply

and

drain

hoses

are

not

connected

properly

¢

tighten

the

clamps

«

replace

the

hose

«

change

the

sealing

«

connect

the

hoses

properly

There

is

a

door

seal

leakage

«

the

door

rubber

seal

is

damaged

«

insufficient

door

pressure

«

change

the

coor

rubber

seal

*

remove

spacers

from

behind

the

hinges

There

is

no

warm

water

in

the

wash

sequence

*

program

is

not

correct

«

the

hoses

are

not

correct

connected

*

incoming

supply

is

not

warm

«

change

program

to

correct

temperature

«

connect

the

supply

hoses

correctly,

the

incoming

supply

to

the

warm

water

inlet

valve.

«use

warm

water

supply,

check

your

warm

water

installation

The

heating

time

is

too

long

«

heating

elements

are

defective

«

wiring

is

damaged

or

wrong

«

calcium

sediments

cover

the

heating

elements

«

change

heating

elements

e

check,

replace

or

repair

wiring

¢

clean

or

replace

the

heating

elements

There

is

too

much

vibration

during

extracting

¢

bolts

of

cabinet

and

reinforcements

are

not

fixed

properly

¢

vibration

switch

is

not

correct

installed

¢

tighten

the

bolts

¢

reinstall

vibration

switch

30

INSTALLATION

AND

MAINTENANCE

MANUAL

100646G

MAYTAG

PUB

DATE

28

JUN

2007.D0C

Loading ...

Loading ...

Loading ...