Loading ...

Loading ...

Loading ...

—~

5

y

a

o

—

3

ee

|

fala

Ce

|

Oo

Ce

|

oun

|

Wee

+ + + + + +

+ + + + + +

SOOO

SSO,

100

437

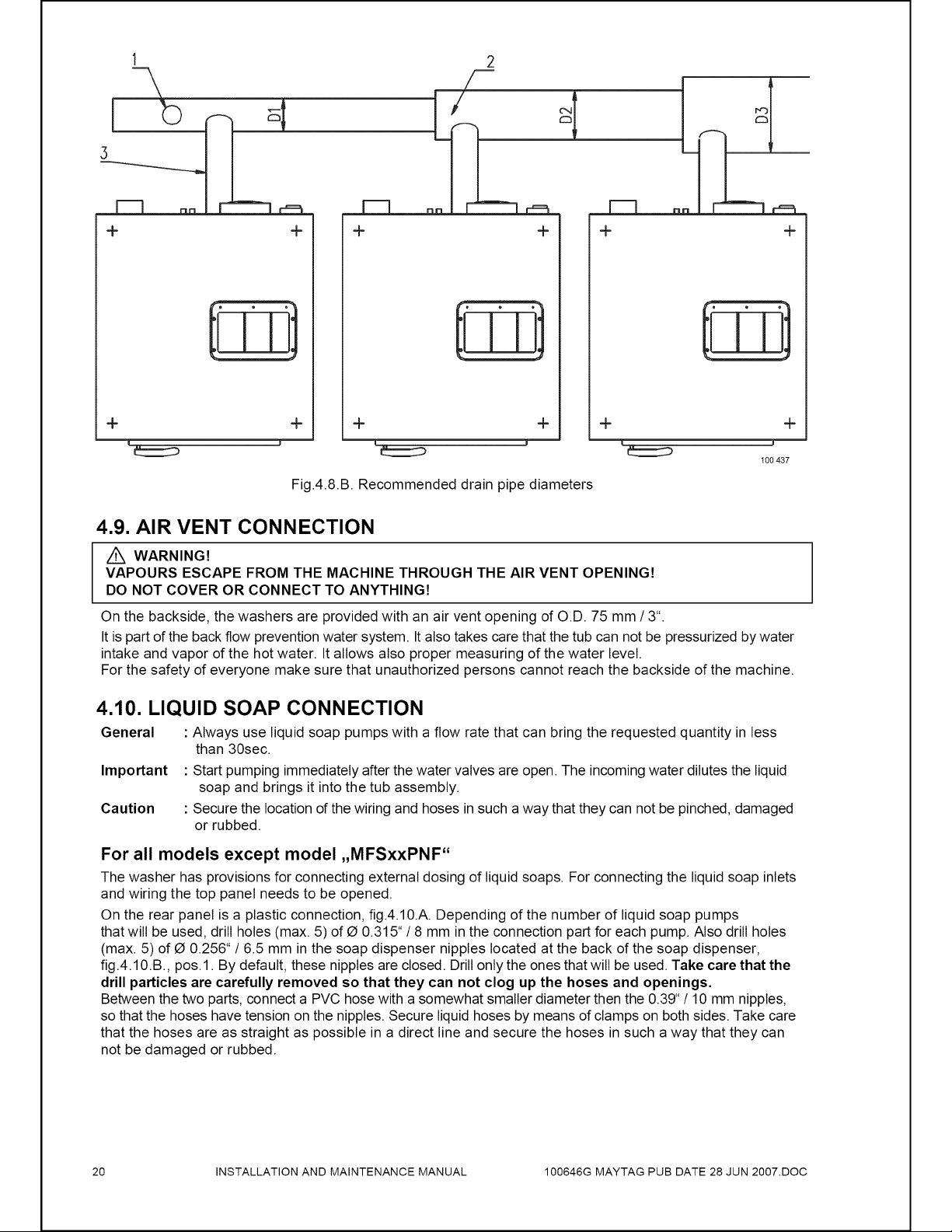

Fig.4.8.B.

Recommended

drain

pipe

diameters

4.9.

AIR

VENT

CONNECTION

Z\

WARNING!

VAPOURS

ESCAPE

FROM

THE

MACHINE

THROUGH

THE

AIR

VENT

OPENING!

DO

NOT

COVER

OR

CONNECT

TO

ANYTHING!

On

the

backside,

the

washers

are

provided

with

an

air

vent

opening

of

O.D.

75

mm

/

3°.

It

is

part

of

the

back

flow

prevention

water

system.

It

also

takes

care

that

the tub

can

not

be

pressurized

by

water

intake

and

vapor

of

the

hot

water.

It

allows

also

proper

measuring

of

the

water

level.

For

the

safety

of

everyone

make

sure

that

unauthorized persons

cannot

reach

the

backside

of

the

machine.

4.10.

LIQUID

SOAP

CONNECTION

General

:

Always

use

liquid

soap

pumps

with

a

flow

rate

that

can

bring

the

requested

quantity

in

less

than

30sec.

Important

:

Start

pumping

immediately

after

the

water

valves

are

open.

The

incoming

water

dilutes

the

liquid

soap

and

brings

it

into

the

tub

assembly.

Caution

:

Secure

the

location

of

the

wiring

and

hoses

in

such

a

way

that

they

can

not

be

pinched,

damaged

or

rubbed.

For

all

models

except

model

,,

MFSxxPNF“

The

washer

has

provisions

for

connecting

external

dosing

of

liquid

soaps.

For

connecting

the

liquid

soap

inlets

and

wiring

the top

panel

needs

to

be

opened.

On

the

rear

panel

is

a

plastic

connection,

fig.4.10.A.

Depending

of

the

number

of

liquid

soap

pumps

that

will

be

used,

drill

holes

(max.

5)

of

@

0.315"

/

8

mm

in

the

connection

part

for

each

pump.

Also

drill

holes

(max.

5)

of

@

0.256"

/

6.5

mm

in

the

soap

dispenser

nipples

located

at

the

back

of

the

soap

dispenser,

fig.4.10.B.,

pos.1.

By

default,

these

nipples

are

closed.

Drill

only

the

ones

that

will

be

used.

Take

care

that

the

drill

particles

are

carefully

removed

so

that

they

can

not

clog

up

the

hoses

and

openings.

Between

the

two

parts,

connect

a

PVC

hose

with

a

somewhat

smaller

diameter

then

the

0.39*

/

10

mm

nipples,

so

that

the

hoses

have

tension

on

the

nipples.

Secure

liquid

hoses

by

means

of

clamps

on

both

sides.

Take

care

that

the

hoses

are

as

straight

as

possible

in

a

direct

line

and

secure

the

hoses

in

such

a

way

that

they

can

not

be

damaged

or

rubbed.

20

INSTALLATION

AND

MAINTENANCE

MANUAL

100646G

MAYTAG

PUB

DATE

28

JUN

2007.D0C

Loading ...

Loading ...

Loading ...