Loading ...

Loading ...

Loading ...

12

installation manual

•Refrigerant containers must be opened slowly.

Always use protective gear when charging the system.

•DO NOT mix refrigerants types.

The outdoor unit is factory charged with refrigerant. Calculate

the added refrigerant according to the diameter and the

length of the liquid side pipe of the outdoor unit/indoor unit

connection.(suitable for throttle outdoor unit)

Table 9-1

Liquid tube(mm) R410A R22

Ø6.35

Ø9.52

Ø12.7

Ø15.9

Ø19

0.022kg/m×(L-5)

0.011kg/m×(L-5)

0.060kg/m×(L-5)

0.030kg/m×(L-5)

0.110kg/m×(L-5)

0.060kg/m×(L-5)

0.170kg/m×(L-5)

0.085kg/m×(L-5)

0.250kg/m×(L-5)

0.125kg/m×(L-5)

0.030kg/m×(L-5)

0.015kg/m×L

0.065kg/m×(L-5)

0.030kg/m×L

0.115kg/m×(L-5)

0.060kg/m×L

0.190kg/m×(L-5)

0.095kg/m×L

0.290kg/m×(L-5)

0.145kg/m×L

orifice in the indoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the outdoorunit

orifice in the indoorunit

orifice in the indoorunit

orifice in the indoorunit

orifice in the indoorunit

9.

AIR EVAC

TION

Safety P recautions

CAUTION

•Use a vacuum pump with a gauge reading lower

than -0.1MPa and an air discharge capacity above

40L/min.

•The outdoor unit does not need vacuuming. DO

NOT open the outdoor unit ’s gas and liquid stop

valves.

•Ensure that the Compound Meter reads -0.1MPa

or below after 2 hours. If after th ree hours of

operation and the gauge reading is still above

-0.1MPa, check if the re is a gas leak or water inside

the pipe. If the re is no leakage, perform another

evacuation for 1 or 2 hours.

•DO NOT use refrigerant gas to evacuate the system.

Evacuation Instructions

Before using manifold gauge and vacuum pump, read their

operation manuals to familiarize yourself with how to use

them properly.

Manifold Gauge

Compound gauge

--76cmH

Low pressure valve

High pressure valve

Charge hose

Charge hose

Vacuum pump

Pressure gauge

Low pressure valve

Fig. 9.1

1. Connect the charge hose of the manifold gauge to

service port on the outdoor unit’s low pressure valve.

2. Connect another charge hose from the manifold gauge

to the vacuum pump.

3. Open the Low Pressure side of the manifold gauge.

Keep the High Pressure side closed.

4. Turn on the vacuum pump to evacuate the system.

5. Run the vacuum for at least 15 minutes, or until the

Compound Meter reads -76cmHG (-1x105Pa).

6. Close the Low Pressure side of the manifold gauge, and

turn o the vacuum pump.

7. Wait for 5 minutes, then check that there has been no

change in system pressure.

NOTE:

the table above refer to the liquid tube.

The number of bends is up to the length of the max height drop.

Usually for each 10m need a bend.

If a negative result is gotten for R from Table 9-1, no refrigerant

needs to be added nor removed.

Additional refrigerant will be twice of R from Table 9-1 if the indoor

unit installed throttle assembly.

NOTE: If the re is no change in system p ressure, unsc rew

the cap f rom the packed valve (high p ressure valve). If

there is a change in system p ressure, the re may be a gas

leak.

Note On Adding Refrigerant

8. Insert hexagonal wrench into the packed valve (high

pressure valve) and open the valve by turning the

wrench in a 1/4 counterclockwise turn. Listen for gas to

exit the system, then close the valve after 5 seconds.

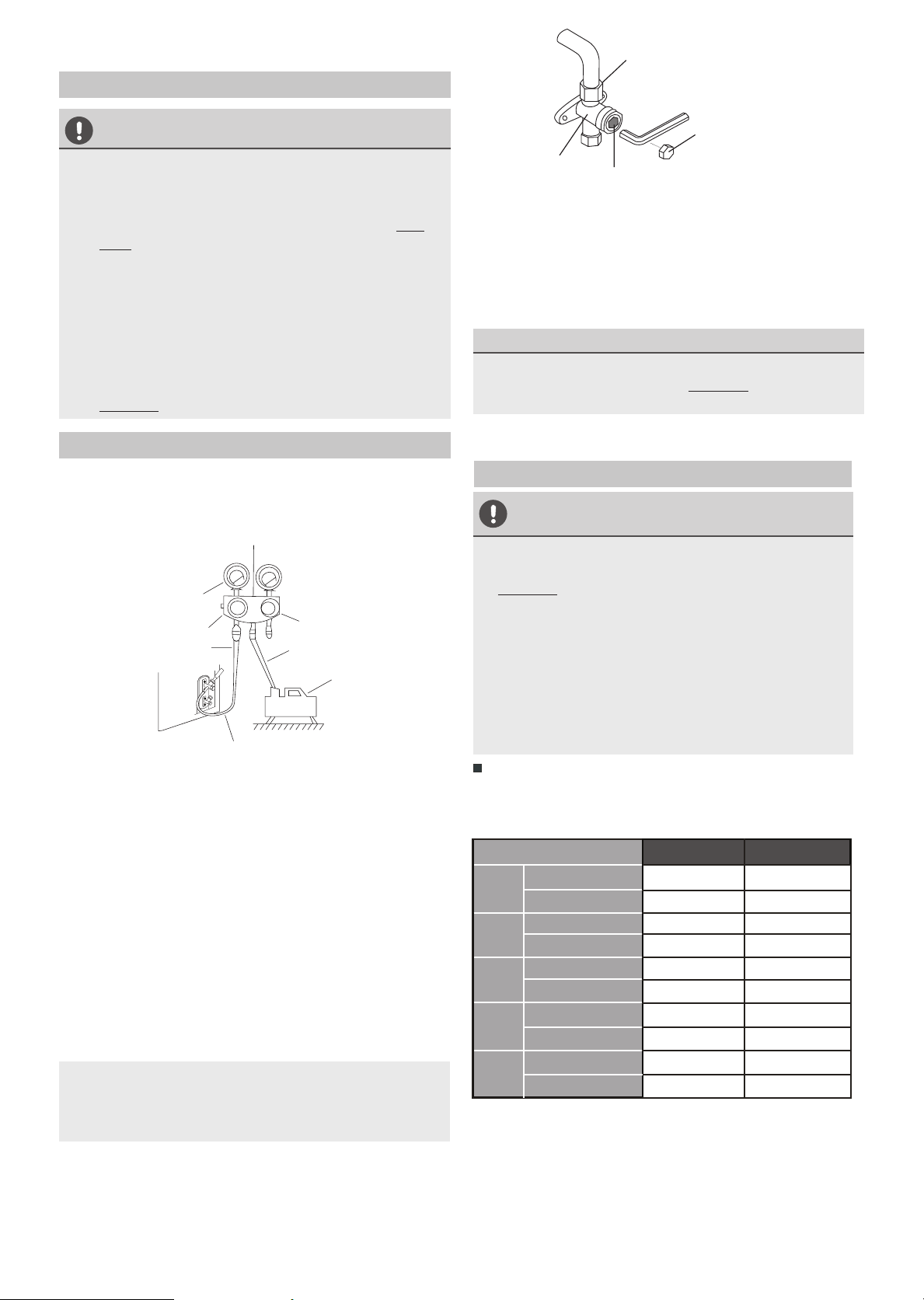

Flare nut

Cap

V alve body

V alve stem

Fig. 9.2

9. Watch the P ressure Gauge for one minute to make su re

that there is no change in p ressure. The P ressure Gauge

should read slightly higher than atmospheric p ressure.

10. Remove the charge hose f rom the service port.

11. Using hexagonal w rench, fully open both the high

pressure and low p ressure valves.

OPEN VALVE STEMS GENT LY

When opening valve stems, tu rn the hexagonal w rench

until it hits against the stoppe r. DO NOT try to fo rce the

valve to open furthe r.

12. Tighten valve caps by hand, then tighten it using the

proper tool.

CAUTION

•Refrigerant charging must be performed after

wiring, vacuuming and the leak test.

•DO NOT exceed the maximum allowable quantity

•

of refrigerant or ove rcharge the system. Doing so

can damage or impact the unit ’s function.

Charging with unsuitable substances may cause

explosions or accidents. Ensure that the appropriate

refrigerant is used.

Loading ...

Loading ...

Loading ...