Loading ...

Loading ...

Loading ...

6

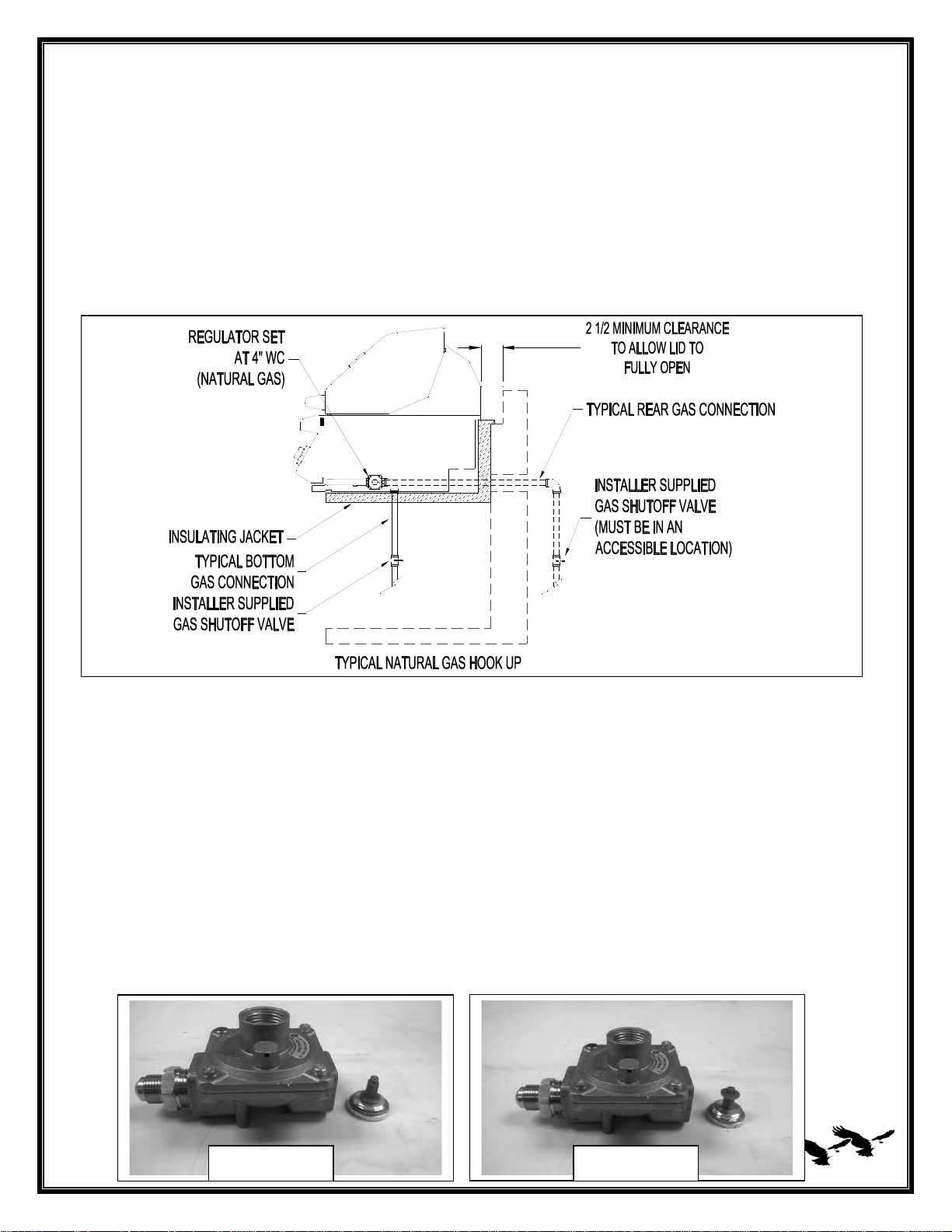

NATURAL GAS INSTALLATION

A typical natural gas installation is shown below. Make sure that the factory-supplied regulator is used

and installed with the arrow mark on the regulator pointing towards the gas grill. Use only pipe sealants that are

approved for use with natural and LP gases. An installer-supplied gas shutoff valve must be installed in an

accessible location.

Please note, when pressure testing, the following statements must be adhered to:

• This gas appliance and its individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of that system at the test pressures in excess of 1/2 psi (3.5 kPa).

• This appliance must be isolated from the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psi (3.5 kPa).

GAS REGULATOR CHECK / CONVERSION

If the gas grill is factory built for natural gas, the regulator supplied is set for 4” water column. The

regulator is convertible to 10 in wc (2.48 kPa) for system LP application. Do not use with a 20-lb LP cylinder.

Make sure that the regulator is set for the correct gas type. To check, remove the brass hex cap. You will find

the conversion plastic pin attached to the cap to the underside of the cap. If the disc (1/2 in. diameter) of the pin

is close to the cap, then the regulator is set for natural gas. If the disc is at the tip of the pin, away from the brass

cap, the regulator is set for system LP application. To convert to natural gas, remove the plastic conversion pin

and invert and replace it back in a manner such that the disc is close to the brass cap. For both natural and LP,

the maximum inlet pressure is 14 in wc (3.5 kPa).

CAUTION: Provide adequate ventilation holes in the enclosure for safety purposes in

the event of a gas leak.

SET TO NG

SET TO LP

Loading ...

Loading ...

Loading ...