Loading ...

Loading ...

Loading ...

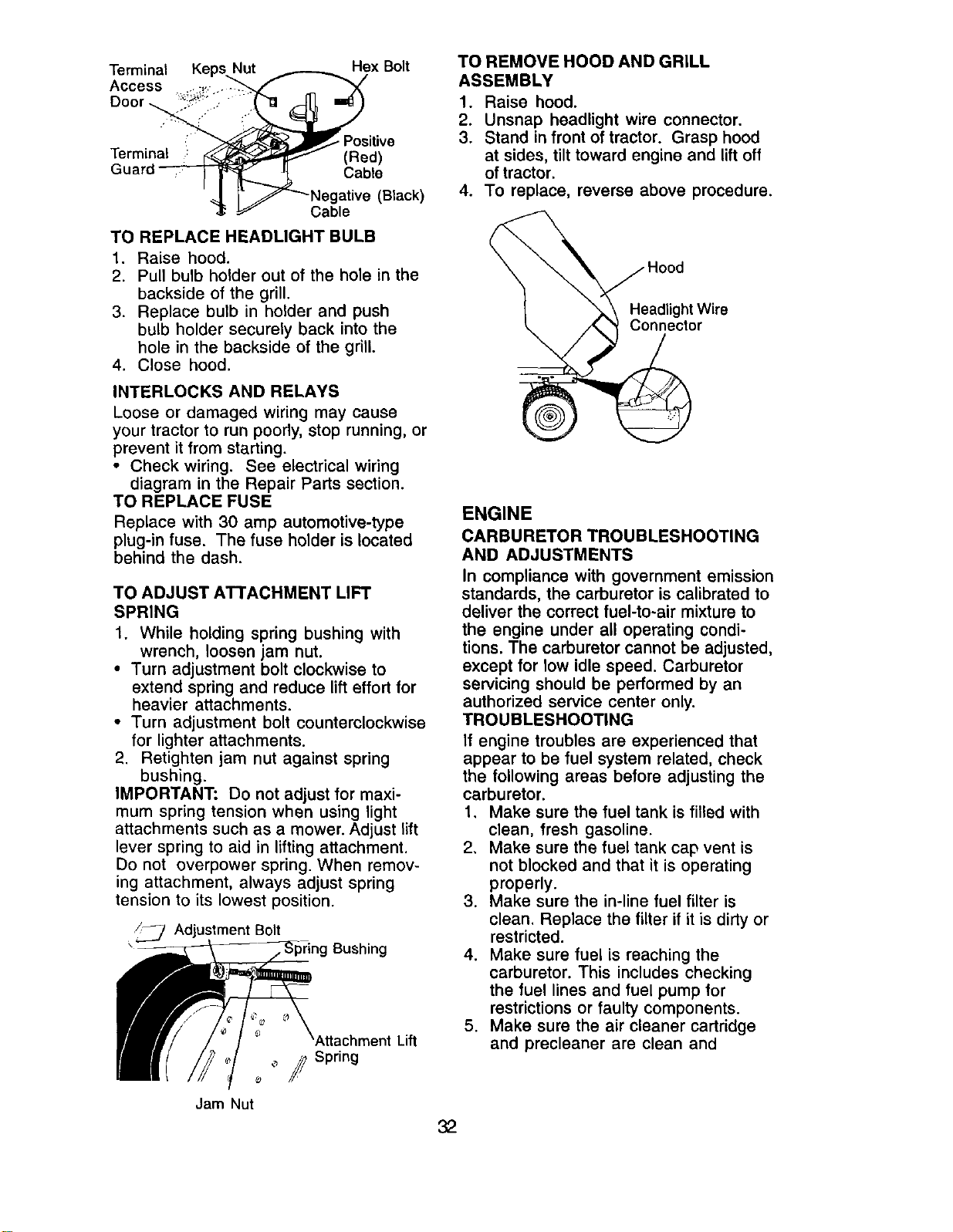

Terminal KepsNut /,....__._ Hex Bolt

Access .:i_.-.. -"'-_ _ _._

Ooor_ _

__'_'_ Positive

Terminal ; _ (Red)

Guard _ Cable

-_ l- JJ_-"-Negarlve (Black)

,!_ _ Cable

TO REPLACE HEADLIGHT BULB

1. Raise hood.

2. Pull bulb holder out of the hole in the

backside of the grill.

3. Replace bulb in holder and push

bulb holder securely back into the

hole in the backside of the grill.

4. Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause

your tractor to run poorly, stop running, or

prevent it from starting.

• Check wiring. See electrical wiring

diagram in the Repair Parts section.

TO REPLACE FUSE

Replace with 30 amp automotive-type

plug-in fuse. The fuse holder is located

behind the dash.

TO ADJUST ATTACHMENT LIFT

SPRING

1. While holding spring bushing with

wrench, loosen jam nut.

• Turn adjustment bolt clockwise to

extend spring and reduce lift effort for

heavier attachments.

• Turn adjustment bolt counterclockwise

for lighter attachments.

2. Retighten jam nut against spring

bushing.

IMPORTANT: Do not adjust for maxi-

mum spring tension when using light

attachments such as a mower. Adjust lift

lever spring to aid in lifting attachment.

Do not overpower spring. When remov-

ing attachment, always adjust spring

tension to its lowest position.

/_ Adjustment Bolt

Bushing

Jam Nut

Lift

TO REMOVE HOOD AND GRILL

ASSEMBLY

1. Raise hood.

2. Unsnap headlight wire connector.

3. Stand in front of tractor. Grasp hood

at sides, tilt toward engine and lift off

of tractor.

4. To replace, reverse above procedure.

Headlight Wire

Connector

ENGINE

CARBURETOR TROUBLESHOOTING

AND ADJUSTMENTS

In compliance with government emission

standards, the carburetor is calibrated to

deliver the correct fuel-to-air mixture to

the engine under all operating condi-

tions. The carburetor cannot be adjusted,

except for low idle speed. Carburetor

servicing should be performed by an

authorized service center only.

TROUBLESHOOTING

If engine troubles are experienced that

appear to be fuel system related, check

the following areas before adjusting the

carburetor.

1. Make sure the fuel tank is filled with

clean, fresh gasoline.

2. Make sure the fuel tank cap vent is

not blocked and that it is operating

properly.

3. Make sure the in-line fuel filter is

clean. Replace the filter if it is dirty or

restricted.

4. Make sure fuel is reaching the

carburetor. This includes checking

the fuel lines and fuel pump for

restrictions or faulty components.

5. Make sure the air cleaner cartridge

and precleaner are clean and

32

Loading ...

Loading ...

Loading ...