Loading ...

Loading ...

Loading ...

TO ADJUST A'n'ACHMENT CLUTCH

The electric clutch should provide years

of service. The clutch has a built-in brake

that stops the pulley within 5 seconds.

Eventually, the internal brake will wear

which may cause the mower blades to

not engage, or, to not stop as required.

Adjustments should be made by your

nearest Sears or other qualified service

center.

1. Make sure attachment clutch and

ignition switches are in "OFF'

position.

2. Adjust the three nylon Iocknuts until

space between clutch plate and rotor

measures .012" at all three slot

locations cut in the side of brake

plate.

NOTE: After installing a new electric

clutch, run tractor at full throttle and

engage and disengage electric clutch 10

cycles to wear in clutch plate.

Rotor Clutch Plate

Slot

Nylon Locknut (3)

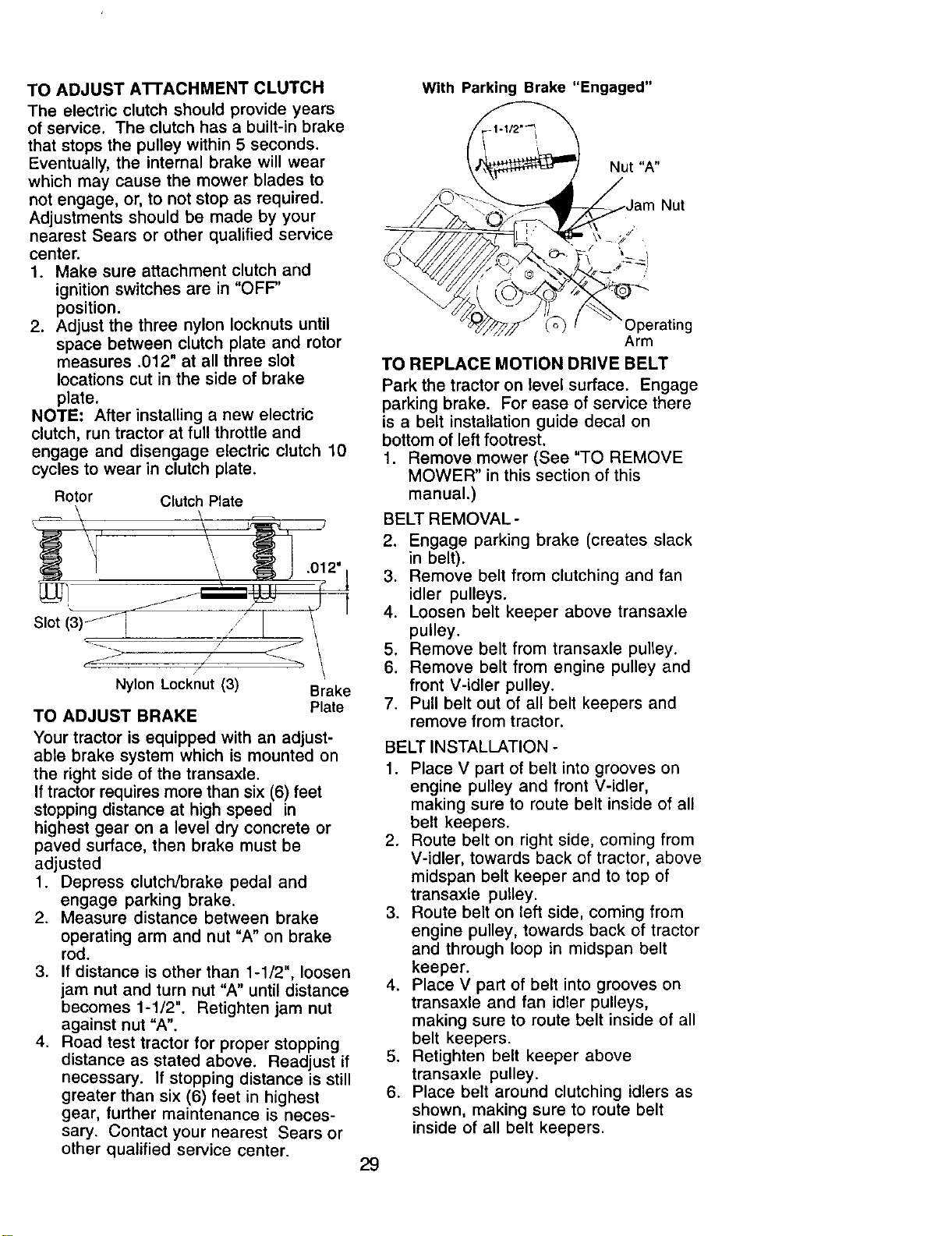

TO ADJUST BRAKE

Brake

Plate

Your tractor is equipped with an adjust-

able brake system which is mounted on

the right side of the transaxle.

If tractor requires more than six (6) feet

stopping distance at high speed in

highest gear on a level dry concrete or

paved surface, then brake must be

adjusted

1. Depress clutch/brake pedal and

engage parking brake.

2. Measure distance between brake

operating arm and nut "A" on brake

rod.

3. If distance is other than 1-1/2", loosen

jam nut and turn nut "A" until distance

becomes 1-1/2". Retighten jam nut

against nut "A".

4. Road test tractor for proper stopping

distance as stated above. Readjust if

necessary. If stopping distance is still

greater than six (6) feet in highest

gear, further maintenance is neces-

sary. Contact your nearest Sears or

other qualified service center.

With Parking Brake "Engaged"

Nut

:)perating

Arm

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface. Engage

parking brake. For ease of service there

is a belt installation guide decal on

bottom of left footrest.

1. Remove mower (See "TO REMOVE

MOWER" in this section of this

manual.)

BELT REMOVAL -

2. Engage parking brake (creates slack

in belt).

3. Remove belt from clutching and fan

idler pulleys.

4. Loosen belt keeper above transaxle

pulley.

5. Remove belt from transaxle pulley.

6. Remove belt from engine pulley and

front V-idler pulley.

7. Pull belt out of all belt keepers and

remove from tractor.

BELT INSTALLATION -

1. Place V part of belt into grooves on

engine pulley and front V-idler,

making sure to route belt inside of all

belt keepers.

2. Route belt on right side, coming from

V-idler, towards back of tractor, above

midspan belt keeper and to top of

transaxle pulley.

3. Route belt on left side, coming from

engine pulley, towards back of tractor

and through loop in midspan belt

keeper.

4. Place V part of belt into grooves on

transaxle and fan idler pulleys,

making sure to route belt inside of all

belt keepers.

5. Retighten belt keeper above

transaxle pulley.

6. Place belt around clutching idlers as

shown, making sure to route belt

inside of all belt keepers.

29

Loading ...

Loading ...

Loading ...