IMPORTANT MANUAL DO NOT THROW A WAY

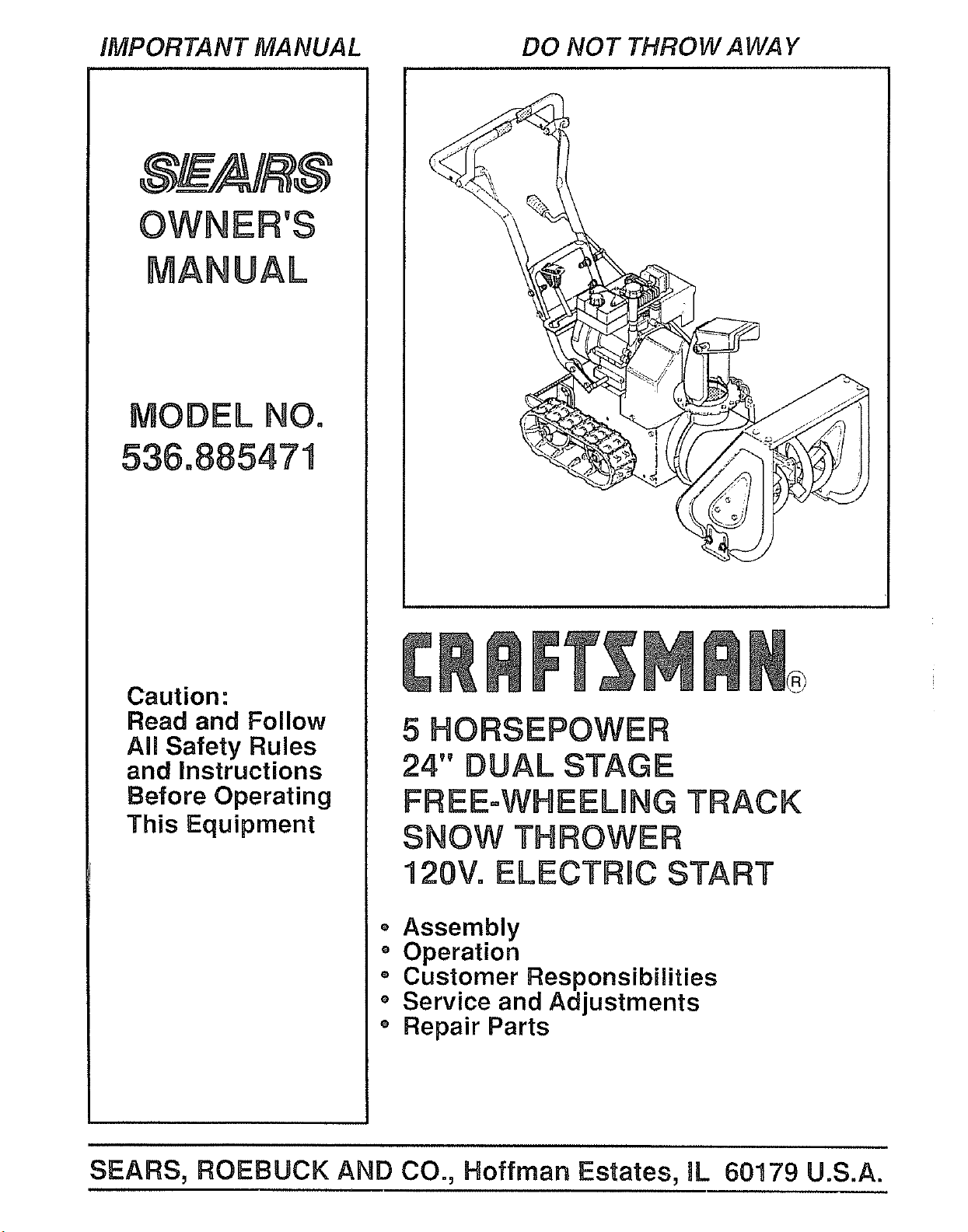

MODEL NO.

536°885471

Caution:

Read and Follow

All Safety Rules

and instructions

Before Operating

This Equipment

5 HORSEPOWER

24" DUAL STAGE

FREE=WHEELING ]'RACK

SNOW THROWER

120V. ELECTRIC START

• Assembly

o Operation

o Customer Responsibilities

o Service and Adjustments

o Repair Parts

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

Loading ...

Loading ...

Loading ...