Loading ...

Loading ...

Loading ...

Read these points before connecting to the gas supply:

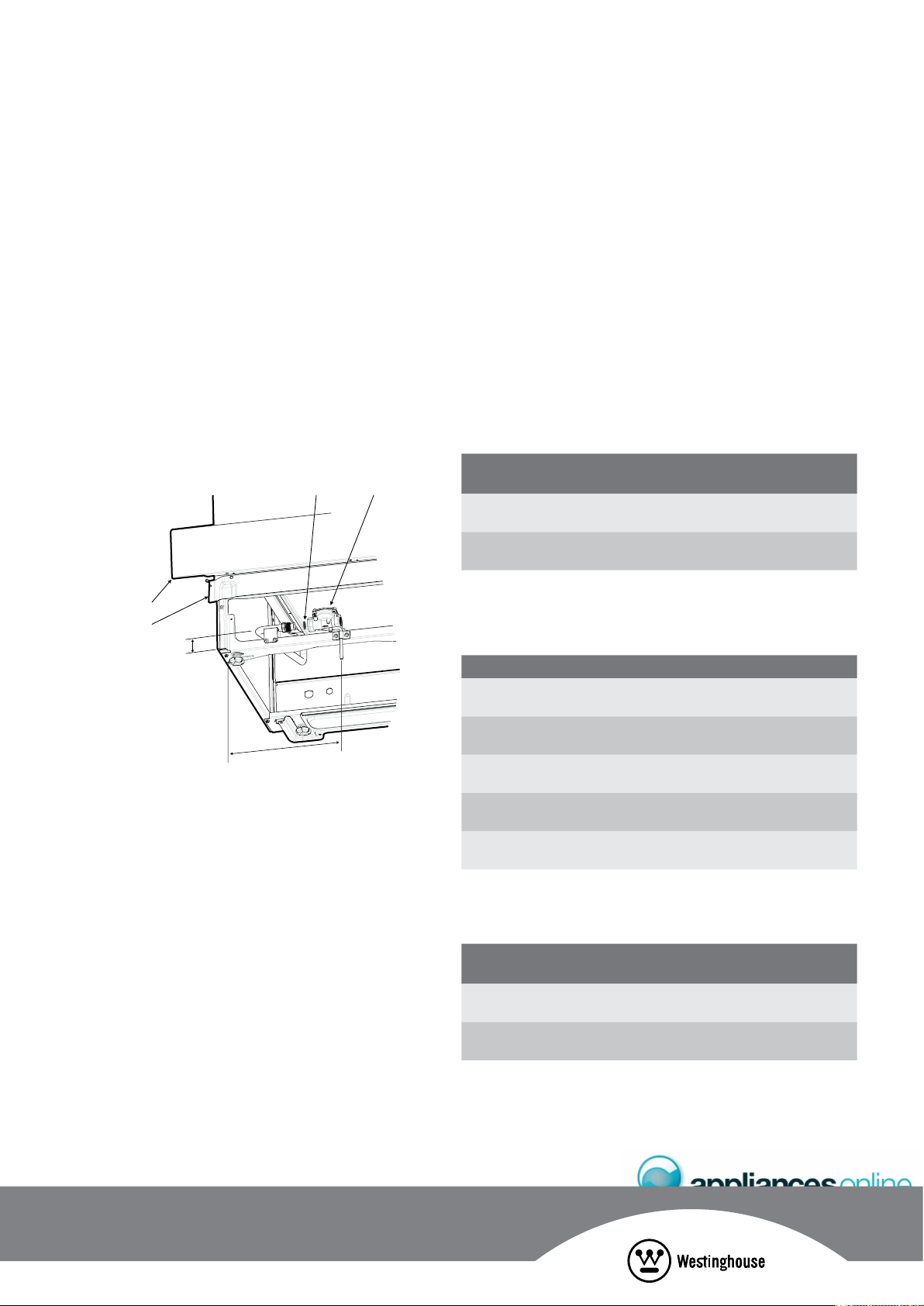

• Slide cooker into nal position checking that anti-tilt bracket

is engaged and that wiring loops and gas supply are free

from jamming and obstacles.

• Fit the supplied pressure regulator for Natural Gas or

supplied test point union for LPG appliances using the

supplied sealing washer. Ensure the arrow is pointing

towards appliance and that the pressure test point is

accessible.

• Make the gas connection to the inlet of the regulator or

test point adaptor using a tting to suit ½” BSP parallel

internal thread found on these ttings. Flexible connections

are not permitted with this appliance.

Kick-panel bracket

70mm

225mm to end

of regulator

Kick-panel

Sealing washer NG regulator

The cooker MUST be installed in compliance with:

• the Australian Standard AS5601 (particular reference to

clause 5.12.1).

• local gas tting regulations, municipal building codes and

other statutory regulations.

The cookers come in two gas types: Natural gas and

Universal LPG. Before installation check that the cooker is

suitable for the gas supply. To do this check the gas type on

the carton sticker or on the data plate behind the bottom of

the oven door.

The following table shows the supply and operating pressures

for various gas supplies.

SUPPLY PRESSURE

at inlet to appliance regulator (if tted)

1.13 (kPa)

Minimum

2.75*

(kPa)

OPERATING PRESSURE

at appliance test point

1.00 (kPa) 2.75 (kPa)

*If the regulator is placed upstream of the cooker inlet, as is normal for

cookers operating on LPG, then the supply pressure and operating pressure

are the same.

The following table shows the injector sizes for each burner.

LOW HEAT

BURNER

1.00 mm 0.55 mm

MEDIUM HEAT

BURNER

1.35 mm 0.70 mm

HIGH HEAT

BURNER

1.60 mm 0.90 mm

INTENSE HEAT WOK

BURNER

1.75 mm 1.00 mm

OVEN

– main injector

1.50 mm 0.82 mm

To work out a suitable pipe size for connection use:

• the information in this table.

Hourly gas consumption for

GSP625/627

51.1MJ/h 44.4MJ/h

Hourly gas consumption for

DSP635

40.6MJ/h 35.4MJ/h

• information about the length of the run, number of elbows,

tees and bends, the available service pressure and the

supply requirements.

AS5601 will help you with this matter.

Gas connection front view

Loading ...

Loading ...

Loading ...