Loading ...

Loading ...

Loading ...

6

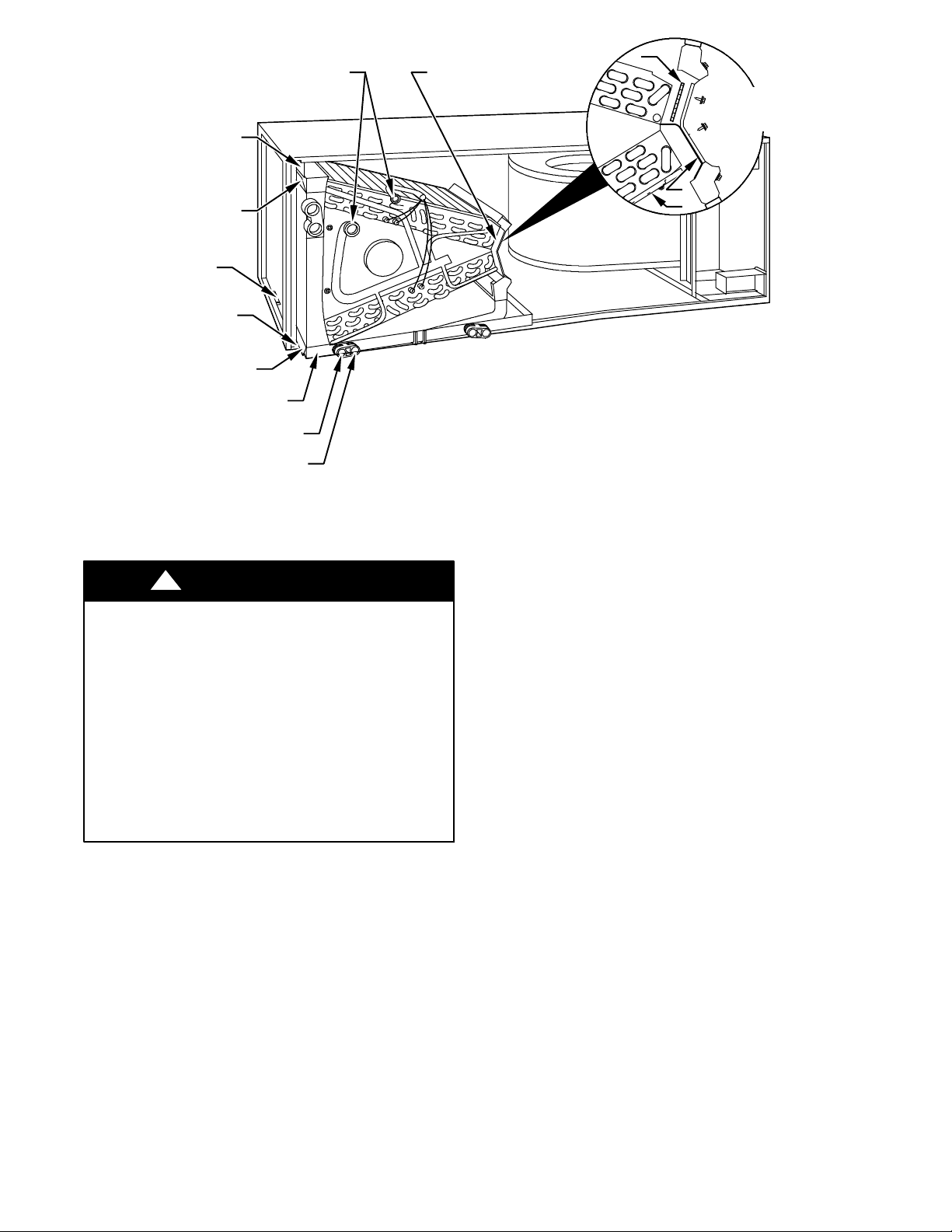

COIL

SUPPORT

RAIL

COIL

BRACKET

DRAIN PAN

SUPPORT

BRACKET

COIL

SUPPORT

RAIL

COIL

BRACKET

HORIZONTAL

DRAIN PAN

PRIMARY DRAIN

HORIZONTAL RIGHT

SECONDARY DRAIN

HORIZONTAL RIGHT

REFRIGERANT

CONNECTIONS

AIR SEAL

ASSEMBLY

A

B

C

HORIZONTAL

RIGHT

APPLICATION

A00071

Fig. 6 - A- Coil in Horizontal- Right Application (FE4A only)

F. Downflow Installations (FE4A and FE5A)

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product or

property damage.

The conversion of the fan coil to downflow requires special

procedures for the condensate drains on both A- coil and

Slope- units. The vertical drains have an overflow hole

between the primary and secondary drain holes. This hole is

plugged for all applications except downflow, but must be

used for downflow. During conversion process, remove

plastic cap covering vertical drains only and discard. Remove

plug from overflow hole and discard. At completion of

downflow installation, caulk around vertical pan fitting to

door joint to retain low air leak performance of the unit.

CAUTION

!

In this application, field conversion of the evaporator is required

using accessory downflow kit along with an accessory base kit.

NOTE: To convert units for downflow applications, refer to

Installation Instructions supplied with kit for proper installation.

For unit size 003, use k it Part No. KFADC0201SLP. For unit sizes

002, 004, 005, and 006, use kit Part No. KFADC0401ACL. Use

fireproof resilient gasket, 1/8- to 1/4- in. thick, between duct, unit,

and floor.

NOTE: Gasket kit number KFAHD0101SLP is also required for

all downflow applications to maintain low air leak/low sweat

performance.

G. Manufactured and Mobile Home Housing Applications

1. Fan coil unit must be secured to the structure using field-

supplied hardware.

2. Allow a minimum of 24- in. clearance from access panels.

3. Recommended method of securing for typical applications

a. If fan coil is away from wall, attach pipe strap to top of

fan coil using No. 10 self tapping screws. Angle strap

down and away from back of fan coil, remove all slack,

and fasten to wall stud of structure using 5/16- in. lag

screws. Typical both sides of fan coil.

b. If fan coil is against wall, secure fan coil to wall stud

using 1/8- in. thick right- angle brackets. Attach brackets

to fan coil using No. 10 self tapping screws and to wall

stud using 5/16- in. lag screws. (See Fig. 7.)

Procedure 3 — Air Ducts

Connect supply- air duct over outside of 3/4- in. flange provided

on supply- air opening. Secure duct to flange with proper fasteners

for type of duct used, and seal duct- to- unit joint.

Duct connection flanges are provided on unit air discharge

connection.

When using FE5A units with 20- kW or FE4A units with 20- ,

24- , and 30- kW electric heaters, maintain a 1- in. clearance from

combustible materials to discharge plenum and ductwork for a

distance of 36” / 914.4 mm from unit. Use accessory downflow

base to maintain proper clearance on downflow installations.

Use flexible connectors between ductwork and unit to prevent

transmission of vibration. When electric heater is installed, use heat

resistant material for flexible connector between ductwork and unit

at discharge connection. Ductwork passing through unconditioned

space must be insulated and covered with vapor barrier.

Loading ...

Loading ...

Loading ...