Loading ...

Loading ...

Loading ...

11

outdoor equipment and will display SYSTEM MALFUNCTION

on its screen. Refer to the User Interface Installation Instructions

for more detail. See Fig. 14.

G. Generator

The FE fan coil G thermostat terminal input can be configured

through the User Interface to recognize a Generator Normally

Open dry- contact output to signal the system that a generator

malfunction condition exists. Wire the generator output in series

with the R and G thermostat connections at the fan coil control

board. The User Interface will display GENERATOR

MALFUNCTION when the G thermostat input is energized. This

function requires the addition of a Generator Self Test Verifier (Part

No. GSV200) which must be purchased separately. Visit

www.GeneratorVerifier.com for details and ordering information.

Refer to the User Interface Installation Instructions for more detail.

See Fig. 14.

H. Ventilation Accessory

The FE fan coil G thermostat terminal input can be configured

through the User Interface to recognize a Normally Open

dry- contact output to signal the system that a Ventilation

Accessory requires fan coil blower operation. Blower operation can

be configured for Low, Med or High speed when the G terminal is

energized. Wire the Accessory output in series with the R and G

thermostat connections at the fan coil control board. Refer to the

User Interface Installation Instructions for more detail. See Fig. 14.

COMM

OAT

HUM C O Y W G R

CLS

OPN

COM

System

Shutdown

Device

System

Shutdown

Device

or

Generator

or

VentilationAccessor

y

A07121

Fig. 14 - “G” Terminal Accessory Wiring

Procedure 9 — Start- Up and Troubleshooting

NOTE: Always check high and low voltage supply to the fan coil

components. Check the integrity of the plug receptacle connections

and fan coil wiring harness prior to assuming a component failure.

A. LED Description:

LEDs built into fan coil control provide installer or service person

information concerning operation and/or fault condition of the fan

coil control and ECM motor. This information is also available at

system user interface in text with basic troubleshooting

instructions. Careful use of information displayed will reduce the

need for extensive manual troubleshooting.

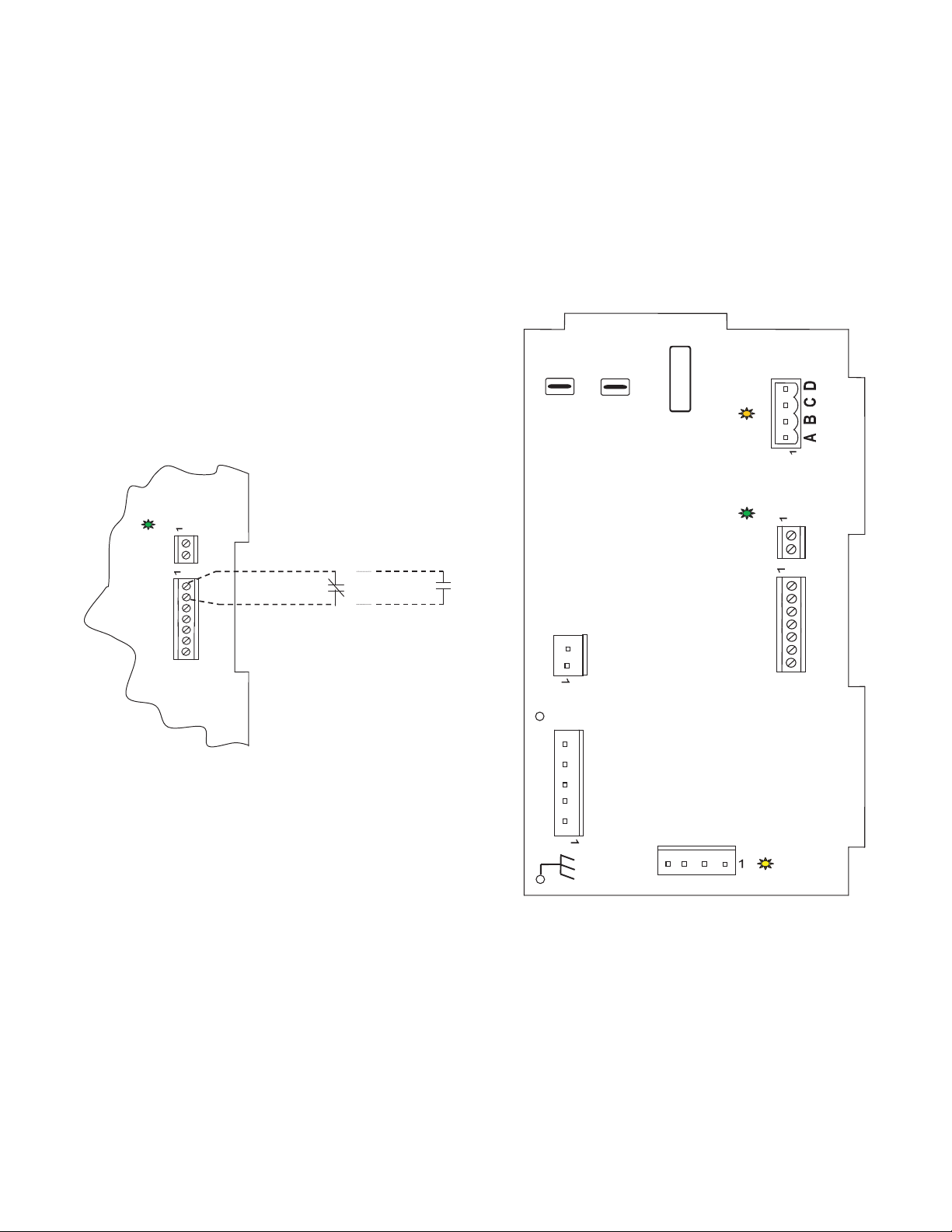

The amber LED located at bottom center of control adjacent to

motor harness plug is motor status LED and it is labeled MOTOR.

A second amber LED located in upper right center of control

adjacent to System Communications connector (A,B,C,D) is the

System Status LED and it is labeled STATUS. The green LED

labeled COMM is also located adjacent to System

Communications connector, below STATUS LED, and is used as

an indicator of system communications status. Status Codes will be

displayed on the STATUS LED using the following protocol:

1. The number of short flashes indicates first digit of code.

2. The number of long flashes indicates second digit of code.

3. A short flash is 0.25 seconds on. A long flash is 1 second

on.

4. The time between flashes is 0.25 seconds.

5. The time between last short flash and first long flash is 1

second.

6. The LED will be off for 2.5 seconds before repeating code.

SEC-1

SEC-2

FUSE 3AMP

HEATER

STATUS

COMM

OAT

MOTOR

HPT

HUM C O Y W G R

OPN

COM

CLS

A07122

Fig. 15 - Detail of FE4A, FE5A Printed Circuit

Board Connections

B. Fan Coil Control Start- Up and System Communications

Troubleshooting:

On power up, green COMM LED will be turned off until

successful system communications are established (this should

happen within 10 seconds). Once communications with user

interface are successful, COMM LED will be lit and held on. At

the same time, amber STATUS LED will be lit and held

continuously on until a request for operating mode is received. The

STATUS LED will be on any time fan coil is in idle mode. If, at

any time, communications are not successful for a period

exceeding 2 minutes, fan coil control will only allow emergency

heating or cooling operation using a common thermostat, a

Loading ...

Loading ...

Loading ...