Loading ...

Loading ...

Loading ...

10

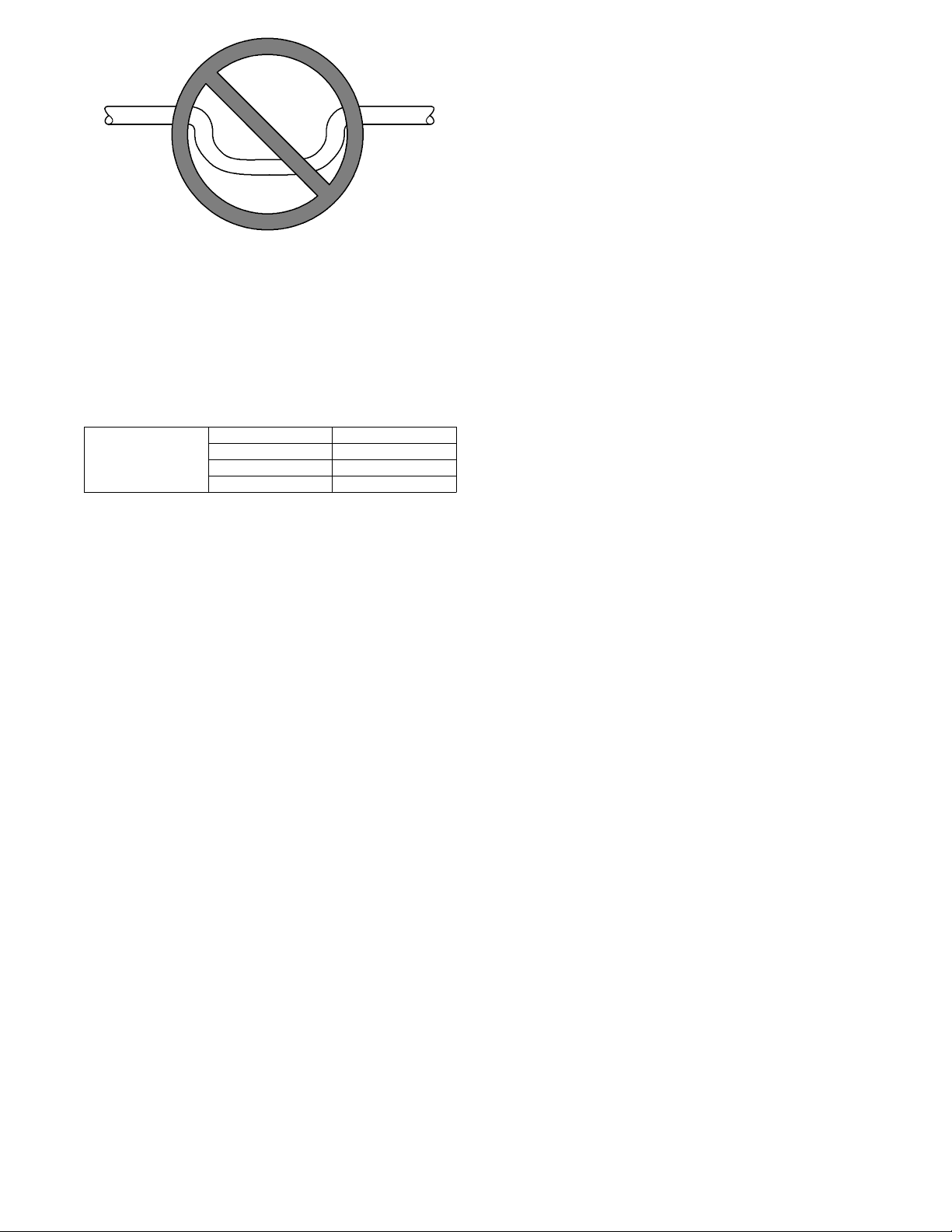

DO NOT USE SHALLOW RUNNING TRAPS!

A03013

Fig. 13 - Insufficient Condensate Trap

IMPORTANT: Factory authorized filters must be used when

locating the filter inside the unit. (See Table 1.) For those

applications where access to an internal filter is impractical, a

field- supplied filter must be installed in return duct system.

Table1–FilterKits

FILT ER KIT

(12 PACK)

PART NUMBER SIZE USED WITH

KFAFK0212MED 002

KFAFK0312LRG 003, 005

KFAFK0412XXL 004, 006

Procedure 7 — Unit Start- Up

Refer to outdoor unit Installation Instructions for system start - up

instructions and refrigerant charging method details.

A. Low - Vo ltage Circuit Fusing and Reference

The low- voltage circuit is fused by a board- mounted 3- amp.

automotive fuse placed in series with transformer SEC1 and R

circuit. The C circuit of transformer circuit is referenced to chassis

ground through a printed circuit run at SEC2 and metal PC board

mounting eyelets. Check to be sure PC Board is mounted securely

using both factory installed screws.

NOTE: Mis- wiring or shorting any of the low voltage

connections may cause the low voltage fuse to open but will not

damage the User Interface or fan coil control. Simply rewire and

replace fuse to correct fault.

Procedure 8 — Accessory Installation

A. Accessory Electric Heaters

Electric heaters may be installed with FE4A, FE5A fan coil per

instructions supplied with electric heater package. See unit rating

plate for factory- approved electric heater kits.

B. Hydronic Heat Applications

The FE fan coil supports 2 types of Hydronic Heat applications:

1. Hot water coil in combination with a heat pump, or hot wa-

ter coil as sole heat source.

2. FE fan coil combined with radiant hot water heat.

In either application, Relay Interface Kit, KFAIF0101HWC, must

be installed in place of an electric heater. The system will identify

that Hydonic Heat has been installed during the initial

commissioning process. The system will treat the hot water coil as

either auxiliary heat in a heat pump application, or as the sole heat

source. Setup options for Hydronic Heat applications are described

in the User Interface Installation Instructions. Options include: Hot

Water Only Operation, Heat Pump Only Operation, Hot Water

Operation during Defrost, Airflow Level Selection, and Blower

ON/OFF Delays.

C. Outdoor Air Thermistor (OAT)

A 2- screw terminal strip is provided for connection of an outdoor

temperature thermistor. This strip is marked OAT. The installation

of an outdoor temperature sensor using the fan coil OAT terminals

is optional. If the outdoor unit is not equipped for communications,

fan coil OAT input can be used to supply outdoor temperature data

for system level functions and for temperature display on User

Interface. Outdoor units with a communicating control are shipped

with a factory installed OAT. This factory installed OAT is used for

all outdoor unit specific and system level functions requiring

outdoor temperature if an OAT is not added to fan coil. If an OAT

is added in the fan coil, the fan coil connected OAT will be used for

system level functions and the factory supplied outdoor unit OAT

will be used for outdoor unit control functions.

Using two wires of field- supplied thermostat wire cable, wire one

lead of thermistor to one screw terminal and the other lead to

remaining screw terminal; there is no polarity to be observed. It is

strongly recommended that two wires be used to connect the

thermistor to eliminate noise interference in temperature reading. If

there are not two spare wires available in cable, one wire may be

used to connect thermistor to OAT screw terminal 1 and the other

lead of the thermistor can be wired to 24VAC COM (C) wire. OAT

screw terminal 1 is terminal located closest to the ABCD system

communications and is marked with a small number 1 next to the

terminal strip.

NOTE: Mis - wiring OAT inputs will not cause damage to either

fan coil control or thermistor. If the thermistor is wired incorrectly,

no reading will appear at User Interface. Re- wire thermistor

correctly for normal operation.

D. Electronic Air Cleaner Connections

When using an electronic air cleaner with FE4A, FE5A fan coil,

use airflow sensor part no. KEAAC0101AAA. The airflow sensor

turns on electronic air cleaner when fan coil blower is operating.

E. Humidifier Connections

The fan coil control terminal marked “HUM” is provided for low

voltage (24VAC) control of a humidifier. No humidistat is required

as User Interface monitors indoor humidity. When commanded to

operate humidifier, the fan coil control will energize the “HUM”

output to turn humidifier on and de- energize HUM output to turn

humidifier off. Wire “HUM” and “C” terminals directly to

humidifier as shown in Fig. 9 or 10.

F. System Shutdown Accessories

The FE fan coil G thermostat terminal input can be configured

through the User Interface to recognize accessories that will shut

the system down in response to a malfunction. Types of devices

may include a Condensate Overflow Switch that is designed for

this purpose. The fan coil can be configured to recognize either

Normally Open or Normally Closed (default) contact devices

through the User Interface Set- Up screens. Wire the accessory

device contacts in series with the R and G thermostat connections

at the fan coil control board. The User Interface will respond to the

accessory device signal by ordering a shutdown of the indoor and

Loading ...

Loading ...

Loading ...