Loading ...

Loading ...

Loading ...

11

Appliance Controls

HOW YOUR STOVE WORKS

Your pellet stove utilizes

a inclined auger fuel feed

system that is operated by

a microprocessor controlled

digital circuit board. The

digital circuit board allows

the inclined auger fuel feed

system to run in a timer-based,

non-continuous cycle; this

cycling allows the auger to run

for a predetermined period

of seconds. The auger pushes

pellets up a chute located at

the front/bottom of the hopper

which in turn falls through

another chute into the burnpot.

Your stove is equipped with an

automatic ignition system that should ignite the fuel within 5-10 minutes from pressing the ON button. As pellets

enter the burn pot and ignite, outside air is drawn across the fuel and heated during the combustion process

which is then pulled through the heat exchanger by the exhaust motor or draft fan. As the stove heats up, room

air is circulated around the heat exchanger by means of a room air blower, distributing warm air into the room.

The amount of heat produced by the stove is proportional to the rate of the fuel that is burned, and this rate

is controlled by the “HEAT RANGE” setting. In order to maintain combustion of the fuel at a desired rate, the air

provided to the burn chamber by the exhaust or draft fan must be maintained precisely. Too little air will result in a

ame that is non-energetic or lazy. If the fuel continues to ow with too little air for long enough, the burn pot will

ll with too much fuel and the re will smother out. To much air will result in a ame that is overactive or aggressive.

The ame in this situation is typically very blue at the bottom and resembles a blow torch. If this situation continues,

the fuel in the burn pot will be consumed and the re will go out. Matching the amount of air required for proper

combustion to the fuel rate is the primary objective in effectively burning pellets of various brands and qualities

in your stove. The air to fuel ratio can be adjusted to allow almost any fuel quality to burn effectively by following

the procedures detailed in the remainder of this manual. Because a forced draft pressure is required for the

combustion process inside your stove, it is extremely important that the exhaust system be properly installed and

maintained. And, that when operating your stove, you make sure that the viewing door is properly sealed.

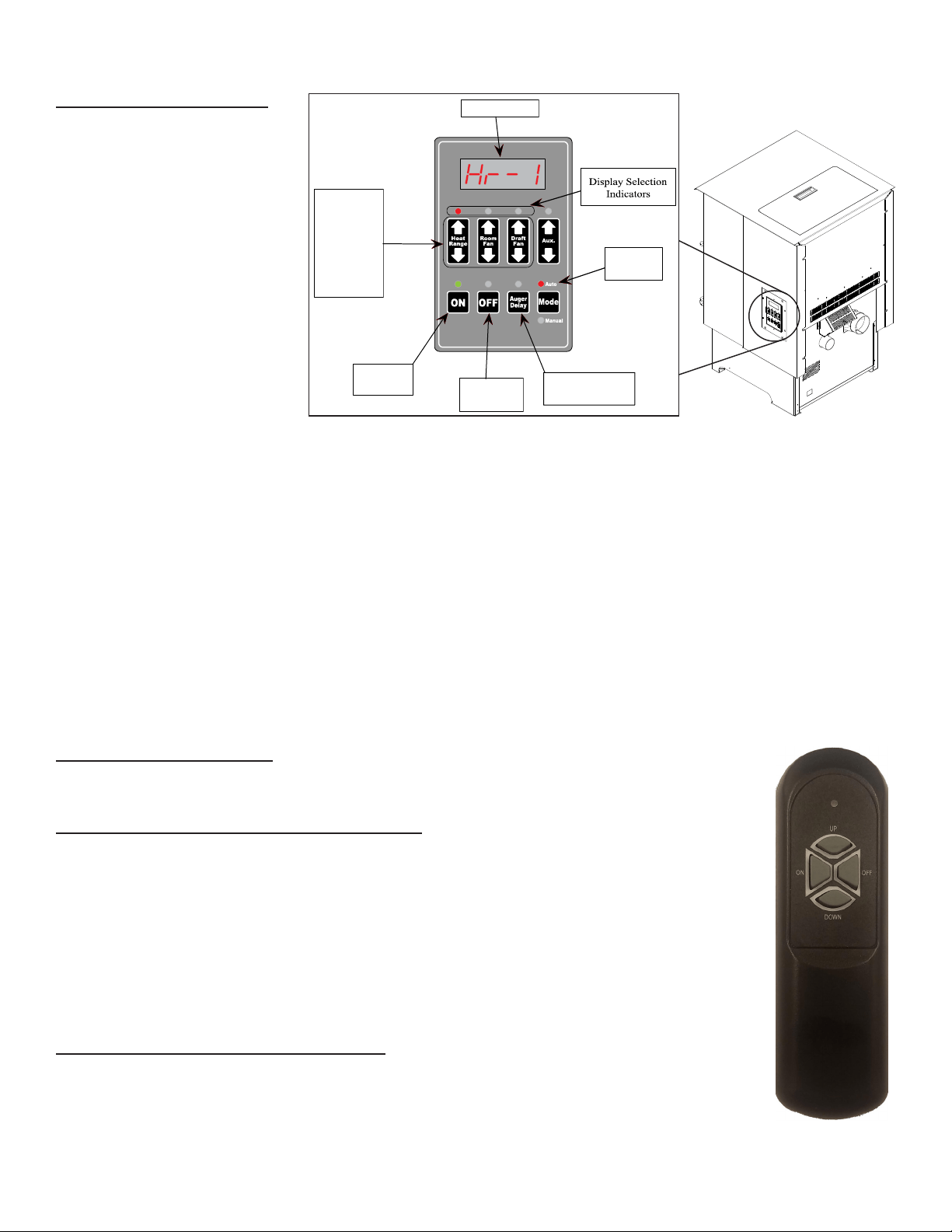

PANEL/REMOTE CONTROLS

The blowers and automatic fuel supply are controlled from a panel on the top of the stove.

The control panel functions are a follows.

A. ON/OFF SWITCH (“POWER” BUTTON)

• When pushed, the stove will automatically ignite. No other re starter is necessary. The

igniter will stay on for at least 10 and up to 12 minutes, depending on when Proof of Fire is

reached. The re should start in approximately 5 minutes.

• After pushing “POWER”, the auger motor is on for 3.5 minutes, off for 1 minute. During the

remainder of the start-up period, the auger motor operates on the heat range “1” setting.

• During start up the heat level advance (Up and Down keys) will change the heat range

indicator level accordingly, but there is no change in the stoves operating conditions until

start-up is completed.

• During start-up ignition must occur within 12 minutes or the stove will error out and show E3.

• During the start-up phase, the Mode key does not function.

B. LEVEL / TEMP ARROW BUTTONS

• These buttons when pushed will set the pellet feed rate, hence the heat output or heat

range of your stove.

• The levels of heat output will incrementally change on the bar graph starting from heat

range “1” to heat range “5”.

4 Digit Display

Up / Down

Buttons :

Heat Range

Room Fan

Draft Fan

Auto Mode

Indicator

Auger Delay

Indicator & Button

Off Indicator

& Button

On Indicator

& Button

Digital Control Panel

Loading ...

Loading ...

Loading ...