Loading ...

Loading ...

Loading ...

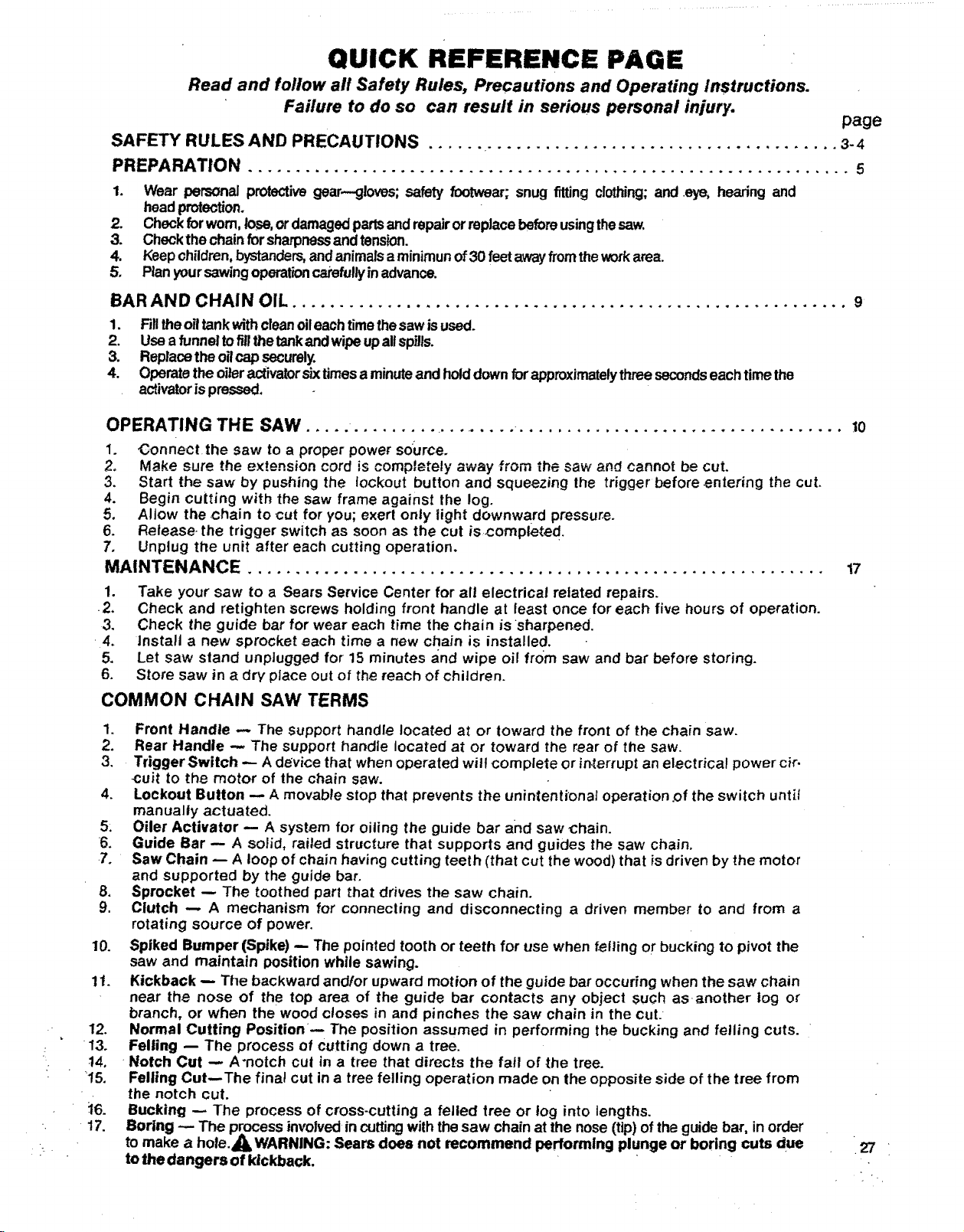

QUICK REFERENCE PAGE

Read and follow all Safety Rules, Precautions and Operating instructions.

Failure to do so can result in serious personal iniury.

page

SAFETY RULES AND PRECAUTIONS ....... . .................................... 3-4

PREPARATION ............................................................... 5

1. Wear persona] protectivegear-gloves; safety footwear;snug fitting clothing;and eye, hearing and

head protection.

2. Checkfor worn,lose, ordamagedpartsandrepairor repJacebeforeusingthesaw,

& Checkthe chainfor sharpnessand tension.

4, Keepchildren, bystanders,andanimalsa minimun of3Ofeet awayfrom theworkarea.

5. Ran your sawingoperationcarefullyinadvance.

BAR AND CHAIN OIL .......................................................... 9

1. Filltheoiltankwithcreanoileachtimethesaw isused.

2. Use afunnel tofittthetankand wipeupallspilts.

3. Replacethe oilcap securely.

4. Operate theoileractivatorsixtimesa minute and holddownfor approximatelythreesecondseachtimethe

activator is pressed,

OPERATING THE SAW ..... ................... .................................. 10

1. Connect the saw to a proper power source.

2. Make sure the extension cord is completely, away from the saw and cannot be cut.

3. Start the saw by pushing the lockout button and squeezing the trigger before entering the cut.

4. Begin cutting with the saw frame against the log.

5, Allow the chain to cut for you; exert only light downward pressure.

6. Release- the trigger switch as soon as the cut is,complete d.

7. Unplug the unit after each cutting operation.

MAINTENANCE ............................................................ !7

1. Take your saw to a Sears Service Center for all electrical related repairs.

2. Check and retighten screws holding front handle at least once for each five hours of operation.

3. Check the guide bar for wear each time the chain is sharpened.

r4. tnsta/l a new sprocket each time a new chain is installed.

5. Let saw stand unplugged for 15 minutes and wipe oil from saw and bar before storing.

6. Store saw in a dry pJace out of the reach of children.

COMMON CHAIN SAW TERMS

12.

: 13.

14.

1. Front Handle _ The Support handle located at or toward the front of the chain saw.

2. Rear Handle _ The support handle located at or toward the rear of the saw.

3. Trigger Switch _ A device that when operated will complete or ir_terruptan electrical power cir.

_uit to the motor of the chain saw.

4. Lockout Button m A movable stop that prevents the unintentiona/operation.of the switch until

manually actuated.

5: Oiler Activator -- A system for oiting the guide bar and saw _chain.

6. Guide Bar -- A solid, railed structure that supports and guides the saw chain.

7. Saw Chain -- A loop of chain having cutting teeth (that cut the wood) that isdriven by the motor

and supported by the guide bar.

8. Sprocket -- The toothed part that drives the saw chain.

9. Clutch _ A mechanism for connecting and disconnecting a driven member to and from a

rotating source of power.

10. Spiked Bumper (Spike) -- The pointed tooth or teeth for use when felling or bucking to pivot the

saw and maintain position while sawing.

1t. Kickback _ The backward and!or upward motion of the guide bar occuring when the saw chain

near the nose of the top ares of the guide bar contacts any object such as another log or

branch, or when the wood closes in and pinches the saw chain in the cut.

Normal Cutting Position m The position assumed in performing the bucking and felling cuts.

Felling -- The process of cutting down a tree.

•Notch Cut _ A-notch cul in a tree that directs the fail of the tree.

Felling Cut--The final cut in a tree felling operation made on the opposite side of the tree from

the notch cut.

_6. Bucking -- The process of cross-cutting a felled tree or log into lengths.

• 17. Boring _ The process involved incuttingwith the saw chain at the nose (tip) of theguide bar, in order

to make a hole.41]I,WARNING: Sears does not recommend performing plunge or boring cuts due

to the dangers of kickback.

Loading ...