Loading ...

Loading ...

Loading ...

.... i ............t '.....................'" , ,,i' "I"'_I_,' '_"':"""'"'i................... , ....,,,,i...........

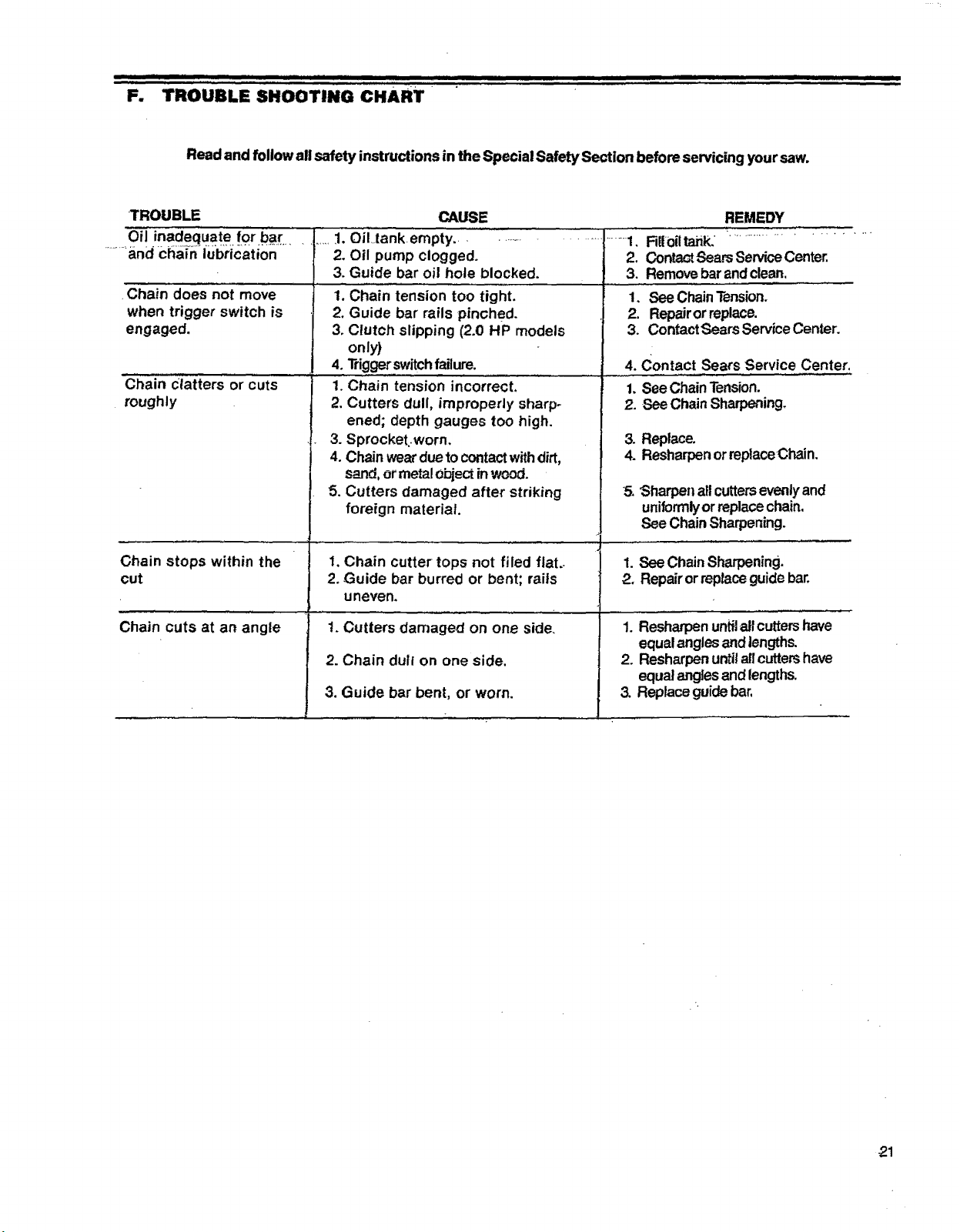

F. I"ROUBI.E SHOOTING CHART

Read and follow all safety instructions in the Special Safety Section before servicing yoursaw.

TROUBLE

Oil inadequate for bar,,

..........and cfla_rt_lu_brication

CAUSE

Chain does not move

when trigger switch is

engaged.

Chain Clatters or cuts

roughly

Chain stops within the

cut

Chain cuts at an angle

.....1. Ofllank empty ...........

2. Oil pump clogged.

3. Guide bar oil hole blocked.

1. Chain tension too tight.

2. Guide bar rails pinched.

3. Clutch slipping (2.0 HP models

only)

4. Triggerswitchfailure.

1.Chain tension incorrect.

2. Cutters dull, improperly sharp*

ened; depth gauges too high.

3. Sprocket..worn.

4. Chain wearduetocontactwithdirt,

sand,ormetalobjectinwDod.

5. Cutters damaged after striking

foreign material.

REMEDY

........1. Rlloiltank. *..........................

2. ContactSearsServiceCenter.

3. Remove bar and clean,

1. See Chain Tension.

2. Repairor replace.

3. ContactSears Service Center.

4. Contact Sears Service Center,

1.see Chain Tension.

2. SeeChain Sharpening.

3. Replace.

4. Resharpen orreplaceChain.

5. Sharpenall cuttersevenlyand

uniformlyor replacechain.

See ChainSharpening.

1. Chain cutter tops not filed flat.. 1.

2. Guide bar burred or bent; rails 2.

uneven.

1.Cutters damaged on one side.

2. Chain dull on one side.

3. Guide bar bent, or worn.

See ChainSharpening.

Repairor replaceguidebar.

1. Resharpenun_ all cuttershave

equalanglesand lengths.

2. Resharpen untilall cuttershave

equal anglesand lengths.

3. Replace guidebar,

21

Loading ...

Loading ...

Loading ...