Loading ...

Loading ...

Loading ...

Maintenance

Beforeinspecting,cleaningor servicingthe machine, shut off engine, discon-

nectsparkplugwire, and make surethatall movingpartshavecometo a com-

plete stop. Removeignitionkeyonelectricstartmodels.

Failure to follow these instructionscan result in personal injury or property

damage.

NOTE: LEFTand RIGHTsides of unit areas viewed

from operator's position behind the handlebars.

REQUIREDMAINTENANCESCHEDULE

BEFOREEVERY EVERY EVERY AS

REQUIREDMAINTENANCE EACH 5 25 100 NOTED

USE HOURSHOURSHOURS

CHECKENGINEOIL LEVEL

CHECKTRIMMERLINES 1

CHECKTRIMMERHEADENGAGEMENT

MACHINECLEANING 3

CHECKNUTSANDBOLTS

CHANGEENGINEOIL 2, 5

SERVICEAIR FILTERSYSTEM 5

CLEANUNDERDECK

GENERALLUBRICATION

INSPECTDRIVEBELT

CLEANENGINE 4

CHECKWEARCUP 6

Chart5-1

ADJUSTING TRIMMER

HEADENGAGEMENT

Thetension on the drive belt must be

correct for proper operation of the

trimmer head. If the tension is correct,

the trimmer headwill rotate whenthe

Trimmer HeadControl Bail is pulled back

againstthe handlebar.

A looseor worn drive beltwill causethe

trimmer headto move slowly, or not at

all,when the control bail is engaged(belt

squealingmay also be noticeable).

If thebelt tension is too tight, the

trimmer headmay rotate beforethecon-

trol bail is engaged,or whenthere is no

freeplay in the control bail. Toadjust

belttension:

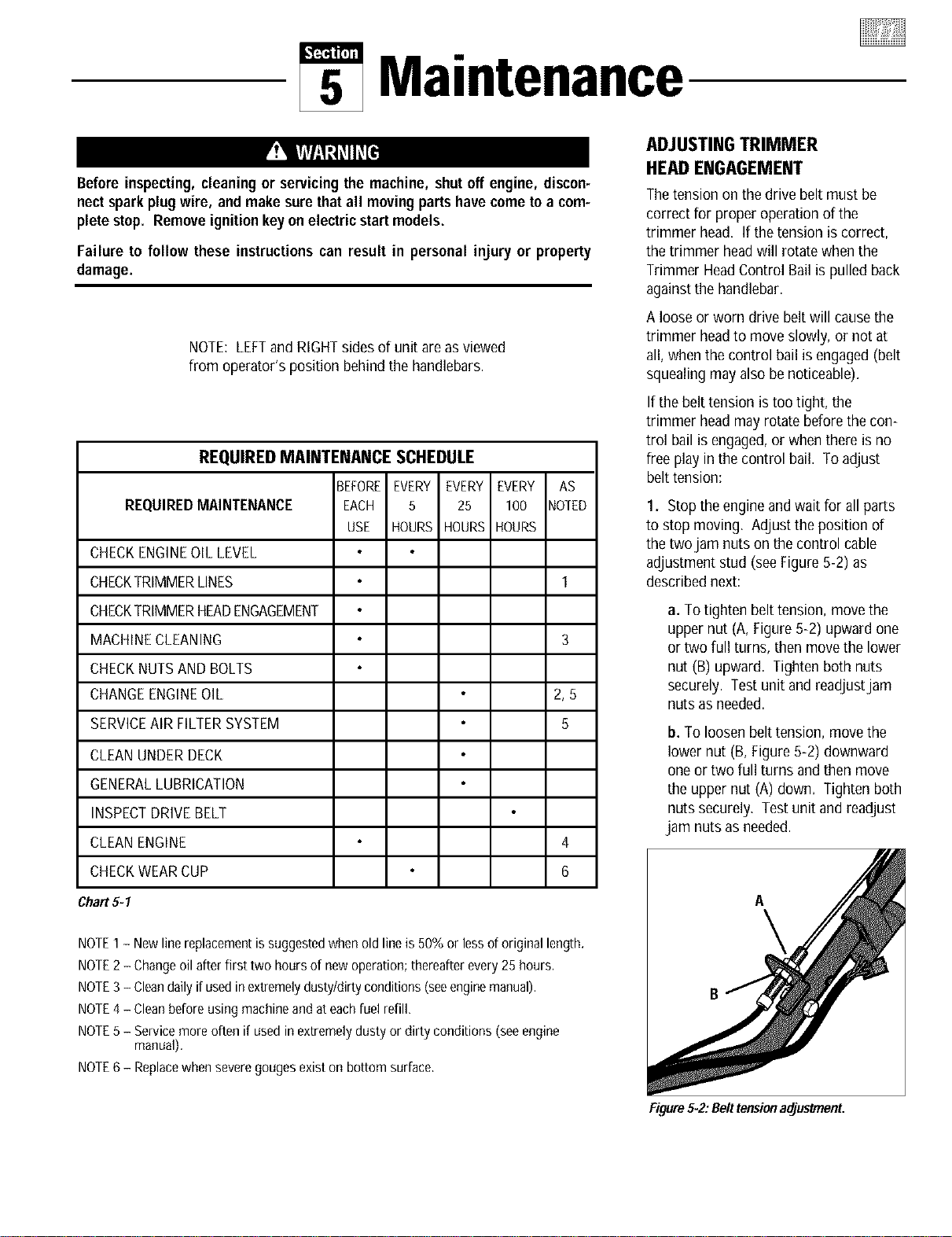

1. Stopthe engine and wait for all parts

to stop moving. Adjust the position of

the two jam nuts on the control cable

adjustment stud (seeFigure5-2) as

describednext:

a. Totighten belt tension, movethe

upper nut (A, Figure5-2) upwardone

or two full turns, then move the lower

nut (B) upward. Tighten both nuts

securely. Test unit and readjustjam

nuts asneeded.

b. To loosenbelt tension, move the

lower nut (B, Figure5-2) downward

one or two full turns and then move

the upper nut (A) down. Tightenboth

nuts securely. Testunit and readjust

jam nuts asneeded.

NOTE1- Newline replacementis suggestedwhen old lineis 50% or lessof original length.

NOTE2- Changeoil after first two hours of newoperation; thereafter every25 hours.

NOTE3- Cleandailyif usedinextremelydusty/dirtyconditions (seeenginemanual).

NOTE4- Cleanbefore using machine and ateachfuel refill,

NOTE5- Servicemore often if used inextremely dusty or dirty conditions (seeengine

manual).

NOTE6- Replacewhen severe gougesexist on bottom surface.

A

B

Figure5-2".Belttensionadjustment.

Loading ...

Loading ...

Loading ...