Loading ...

Loading ...

Loading ...

CARE AND MAINTENANCE

Model. 358-350842 (Craftsman 2.1) Model 358.350870 (Craftsman 2.1 PS) Model 358.350880(Craftsman 2.3 PS/VL)

Follow these helpful hints on care and maintenance to

get the best possible service from your saw, to prevent

major breakdown and costly repair bills. Careful servicing

of your saw is one of the most important steps in preven-

AIR Fi LTER AND CARBURETOR

To clean the air filter or adjust the carburetor, loosen the

filter cover screw (ahead of choke knob) and remove it

and the air filter cover. The air filter element should be

removed after evew 10 hours use and rinsed out in gaso-

line or fue! and oil mix. Squeeze it out well and be sure

the filter element fits into the cavity neatly without folds,

and flush with the top surface. See figure 6. Allow filter

element to dry before restarting engine or mixture will be

too rich;

CARBURETOR ADJUSTMENTS

General:

Carburetor adjustments are made at our factory and wil|

be correct for most app ications. Further adjustments may

be required due to altitudes above 4000 ft., brands!age of

fuel used, and atmospheric conditions.

Caution:

The needles and associated parts will be damaged if Over-

tightened.

Adjustments:

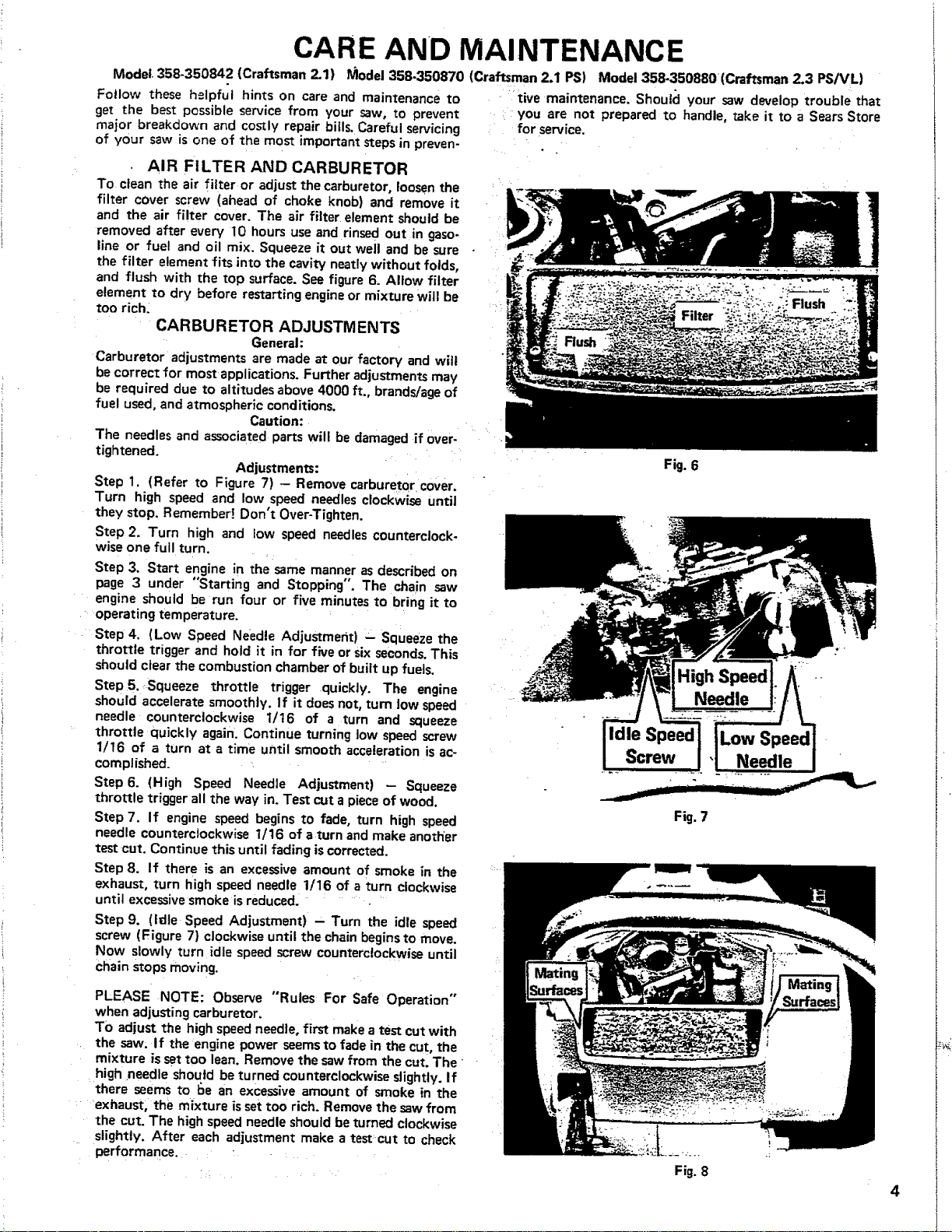

Step 1. (Refer to Figure 7) -- Remove carburetor cover,

Turn high speed and low speed needles clockwise until

they stop, Remember! Don't Over-Tighten.

Step 2. Turn high and low speed needles counterclock-

wise one full turn.

Step 3. Start engine in the same manner asdescribed on

page 3 under "Starting and Stopping". The chain saw

engine should be run four or five minutes to bring it to

operating temperature.

Step 4. (Low Speed Needle Adjustmeht) " Squeeze the

throttle trigger and hold it in for five or six seconds.This

should clear the combustion chamber of built up fuels.

StepS. Squeeze throttle trigger .quickly. The engine

should accelerate smoothly. If it does not, turn low speed

needle counterclockwise 1/16 of a turn and squeeze

throttle quickly again. Continue turning tow speed screw

1/16 of a turn at a time until smooth acceleration isac-

complished.

Step6. (High Speed Needle Adjustment) -Squeeze

throttle trigger all the way in. Test cut a piece of wood.

Step 7. If engine speed begins to fade, turn high speed

needle counterclockwise 1/16 of aturn and make anoth'er

test cut. Continue this until fading is corrected.

Step 8. If there is an excessive amount of smoke in the

exhaust, turn high speed needle 1/16 of a turn clockwise

until excessivesmoke is reduced. .........

Step 9. (Idle Speed Adjustment) -- Turn the idle speed

screw (Figure 7) clockwise until the chain beginsto move.

Now slowly turn idle speed screw counterclockwise until

chain stops moving.

"live maintenance. Shoutct your saw develop trouble that

_, you are not prepared to handle, take it to a Sears Store

for service.

Fig. 6

Needle

Idle Speed Low Speed

Screw Needle

Fig. 7

PLEASE NOTE: Observe "Rules For Safe Operation"

when adjusting carburetor.

TO adiust the high speedneedle, first make a test cut with

the saw; If the engine power seemsto fade in the cut, the

mixture issettoo lean. Remove the saw from the cut. The"

high needle should be tu rned counterclockwise slightly. If

there seems to !_ean excessive amount of smoke in the

exhaust, the mixture is set too rich. Remove the saw from

the cut. The high speed needle should be turned clockwise

slightly. After each adjustment make a testcut to check

performance. :....

Fig. 8

4

Loading ...

Loading ...

Loading ...