Loading ...

Loading ...

Loading ...

Model 358-350880 (Craftsman 2.3 PS/VL)

The rubber,vibration" mounts are designed so that a failure

of one of the mounts will not affect the safety of the saw.

Operation of the saw With a broken rubber mount may

cause excessive wear to other components, resulting in a

hazardous situation. Should a rubber mount break, take it

to a Sears Store immediately and have it replaced.

Check a|l vibration mount screws and nuts for tightness

every two to three hours of operating time.

Craftsman 2.1 PS and Craftsman 2.3 PS/VL are equipped

with a sprocket nose bar. The sprocket nose does not re-

quire grease. Bearings have been greased and sealed at the

factor/, Remember, keep the saw chain well oited. A well

oiled saw chain witl greatly increase the life of saw chain,

bar and saw chain drive sprocket.

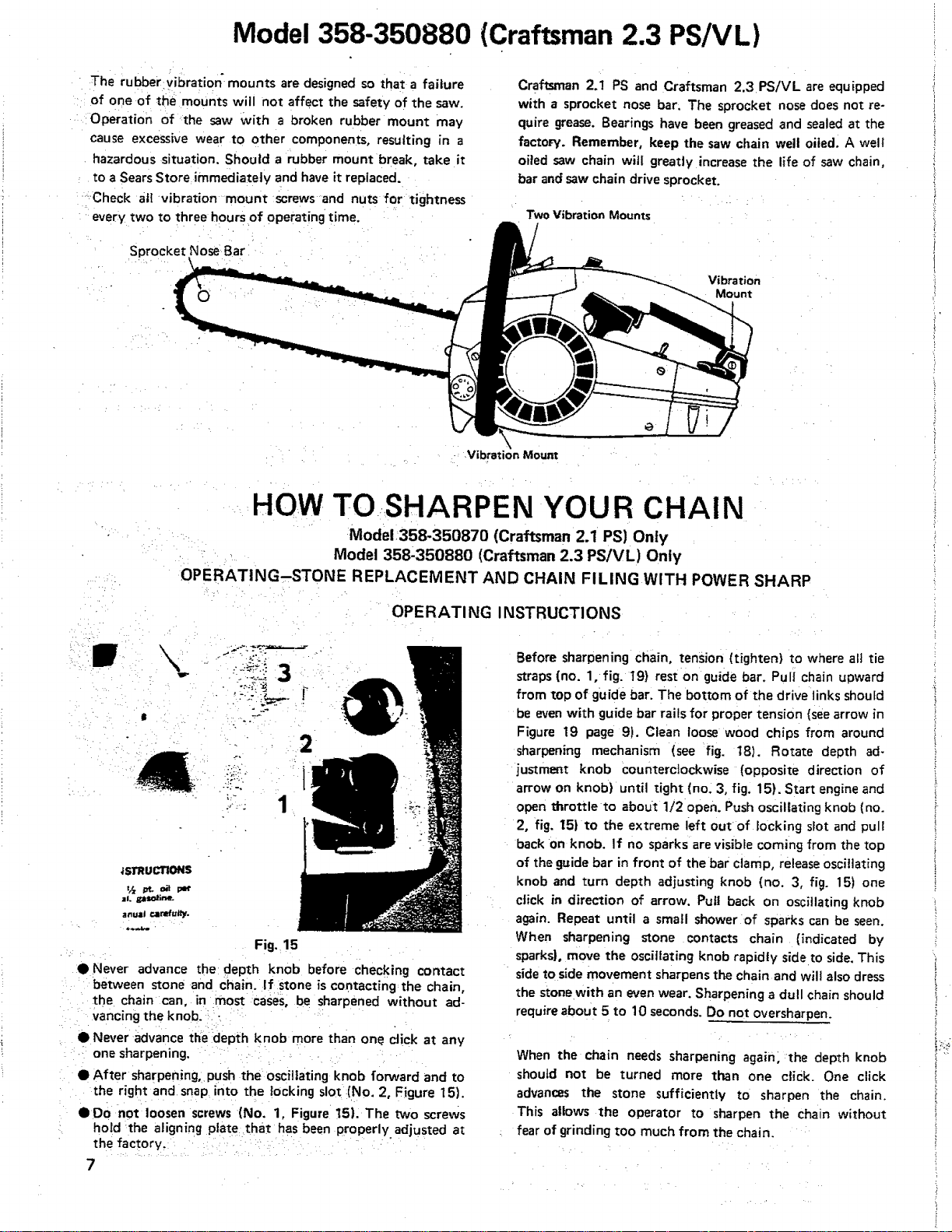

Two Vibration Mounts

Sprocket Nose Bar

Vibration

Mount

Vibration Mount

O

HOW TO SHARPEN YOUR CHAIN

Model 358-350870 (Craftsman 2.1 PS) Only

Model 358-350880 (Craftsman 2.3 PS!VL) Only

OPERATING-STONE REPLACEMENT AND CHAIN FILING WITH POWER SHARP

OP ERATI NG INSTRUCT! ONS

_SI"RUCI30NS

½ ;o_.._ per

aL _lt, oline.

anua! camfu_l,/.

Fig. 15

• Never advance the depth knob before checking contact

: between stone and Chain. If stone is contacting:the chain,

the chain can. inmost cases, be sharpened without ad-

Vancing the knob.- : _::

• Never advance the depth knob more than one. click at any

• one sharpening. : ,

• After sharpening, push the oscillating knob forward and to

the right and snap into the locking slot :(No. 2, Figure 15).

• Do not loosen screws (No. 1, Figure 15). The two screws

hoJdthe aligning plate that has been properly adjusted at

the factory,_ _ :, _ i i i "

7

Before sharpening chain, tension (tighten) to where alt tie

straps (no. 1, fig. 19) rest on guide bar. Pull chain upward

. .

from top of guide bar. The bottom of the drive links should

be evenwith guide bar rails for proper tension (seearrow in

Figure 19 page 9). Clean loose wood chips from around

sharpening mechanism (see fig. lB). Rotate depth ad-

justment knob counterclockwise (opposite direction of

arrow on knob) until tight (no. 3, fig. 15). Start engineand

open throttle to about 1/2 open. Pushoscillating knob (no.

2, fig. 15) to the extreme left outof locking slot and pull

back on knob. If no sparks are visible coming from the top

of the guide bar in front of the bar clamp, release oscillating

knob and turn depth adjusting knob (no. 3, fi_]. 15) one

click in direction of arrow. Pull back on osci!lating knob

again. Repeat until a small shower of sparks can be seen.

When sharpening stone contacts chain (indicated by

sparks), move the oscillating knob rapidly side to side. This

sideto side movement sharpensthe chain and will also dress

the stone with an even wear. Sharpening a dull chain should

require about 5 to 10 seconds.Do not oversharpen.

When the chain needs sharpening again_ the depth knob

should not be turned more than one click. One click

advances the stone sufficiently to sharpen the chain.

This allows the operator to sharpen the chain without

fear of grinding too much from the chain.

Loading ...

Loading ...

Loading ...