Loading ...

Loading ...

Loading ...

Part number 550-100-214/1220

– 22 –

CONDENSING GAS BOILER — 110/155 Advanced Manual

Blr 1

Blr 2

Blr 3

Blr 4

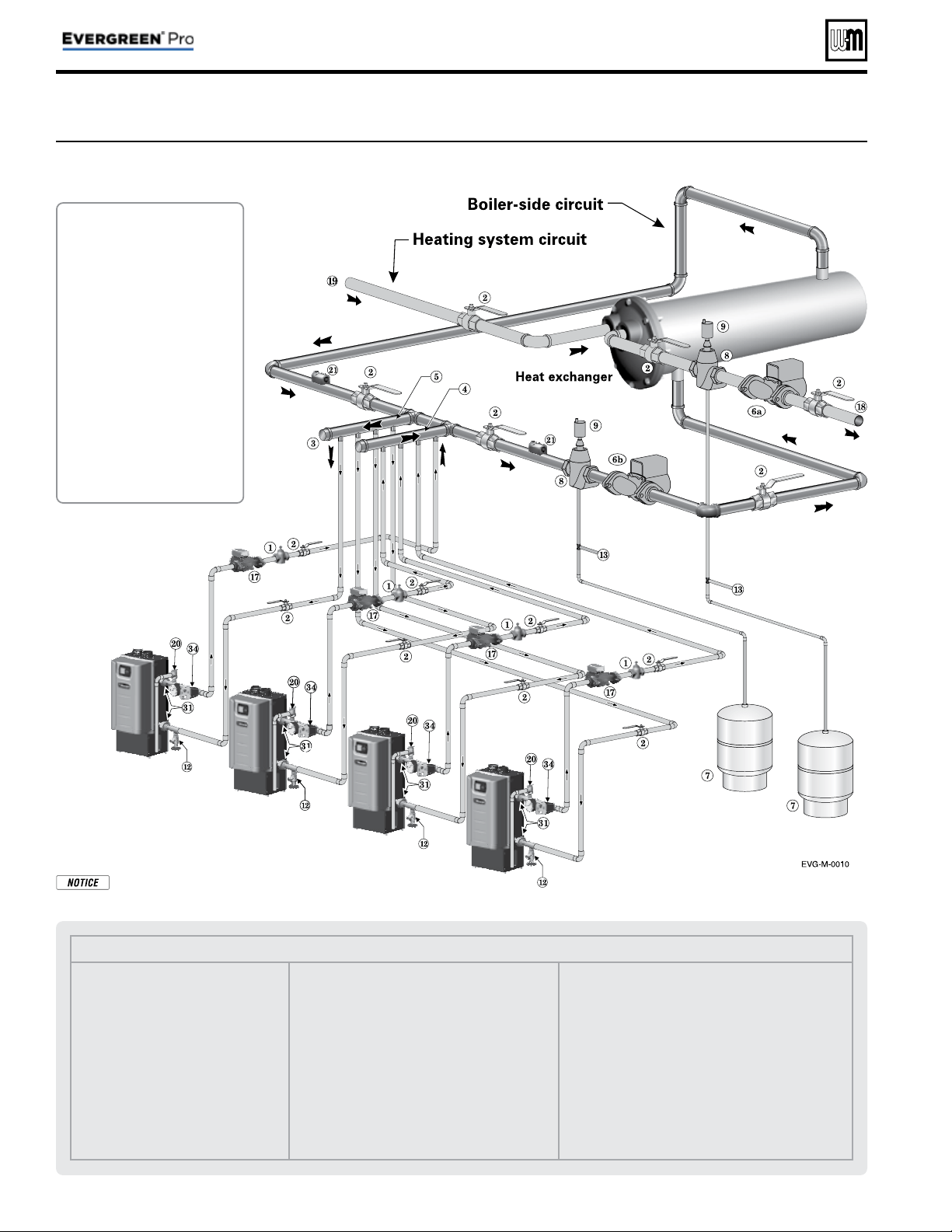

Fast-Track Setup — Typical Application C

Figure 12

Typical Application C —

Piping layout — typical piping for multiple

Evergreen

®

boilers, using isolation

exchanger (adjust boiler connections as required for other boiler models)

Legend — Figure 12

1 Flow/check or spring check valve.

2 Isolation valves (when used).

3 Cap.

4 Easy-Fit® Manifold (supply) — layout

and size per page 7 .

5 Easy-Fit® Manifold (return) — layout

and size per page 7 .

6a Heating system circulator

(exchanger tube-side).

6b Heat exchanger shell-side circulator

7 Expansion tanks (diaphragm type).

8 System air eliminator.

9 System automatic air vent.

12 Boiler drain valves.

13 Cold water supply connections (per applicable

codes).

17 Boiler circulator — circulates water between

boiler and Easy-Fit® Manifolds.

18 Heating system supply.

19 Heating system return.

20 Boiler relief valve and discharge piping,

installed per Evergreen

®

boiler manual.

21 Strap system supply and return sensors to lines

as shown, at least 6 pipe diameters (but no more

than 3 feet) from boiler connection tees. For

redundancy, you can install multiple sensors, each

connected to a different boiler.

31 Unions.

34 Low water cutoff.

Notes:

1. Contact heat exchanger manufacturer for heat ex-

changer shell-side and tube-side piping and circulator

requirements. Tube-side fl ow and temperatures must

meet heating system requirements.

2. Contact heat exchanger manufacturer for sizing heat

exchanger.

3. Heat exchanger shell-side circuit requires its own

expansion tank as shown.

4. Heating system circuit requires its own expansion

tank, as shown, plus its own relief valve set to protect

heating system and heat exchanger piping and com-

ponents.

5. When individual isolation valves are used, individual

boiler and level controls may be required.

Use isolation heat

exchanger for:

1. Large volume systems with high

mineral content in water.

2. Systems exposed to untreated

quantities of makeup water.

3. Old systems severely contami-

nated with scale and rust buildup

inside piping and heat distribu-

tion units.

4. Process applications.

5. Commercial service water ap-

plications.

6. High water pressure applications,

requiring pressure relief setting

in heating system more than 80

PSIG (tall buildings). See notes

below.

Heat exchanger type — This illustration shows a shell

and tube exchanger. Other exchanger types may be used if

suitable for the system water conditions.

Loading ...

Loading ...

Loading ...