Loading ...

Loading ...

Loading ...

page 8

OPERATION

Soft Rubber Gear Case Cover (Fig. 1)

The soft rubber gear case cover (J) is designed to eliminate metal gear case scuffs on painted or

polished surfaces.

The soft rubber gear case cover can be removed if required. To take off the cover, remove the

three mounting screws and lift the cover over the gear case.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing

attachments or accessories. Before reconnecting the tool, depress and release the

trigger switch to ensure that the tool is off.

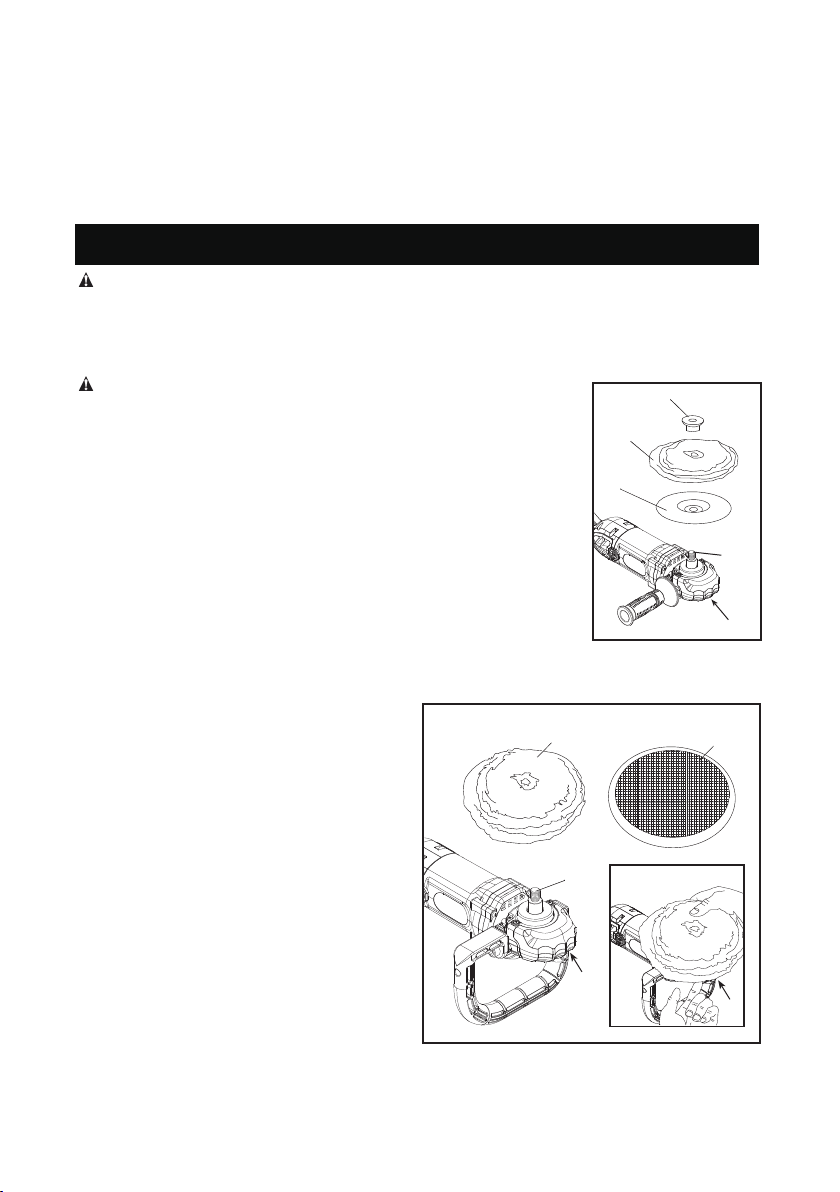

FIG. 3A

M

N

O

E

I

I

Q

FIG. 3B

E

E

Attaching and Removing Polishing Pads (Fig. 3A&3B)

WARNING: To reduce the risk of serious personal injury, do not allow

1. Attach hook and loop foam or wool pad (P)

to hook and loop backing pad (Q), being

careful to center the backing pad (Q) with

the foam or wool pad.

2. Screw backing pad (Q) onto spindle (I),

while depressing spindle lock button (E).

any loose portion of the polishing bonnet or its attachment strings to spin

freely. Tuck away or trim any loose attachment strings. Loose and spinning

attachment strings can entangle your ngers or snag on the workpiece.

NOTE: This tool may use either type of polishing pad assembly described

below.

TO ATTACH POLISHING PAD WITH RUBBER BACKING PAD (FIG. 3A)

1. To attach polishing pad (N), push the hub of the clamp washer (M) through

the hole in the center of the polishing pad as far as it will go.

2. Engage the hexagonal hole in the backing pad (O). Holding the three pieces

rmly together, place the assembly on the tool spindle (I).

3. Depress the spindle lock button (E) while turning the pads clockwise to thread

them

completely on the spindle.

TO ATTACH POLISHING PAD WITH HOOK AND LOOP BACKING PAD (FIG. 3B)

TO REMOVE PADS

Depress the lock button (E) and turn the pad

by hand in the opposite direction until the pad

snaps into the lock position.

Once the pad is snapped into the lock position

ensure the pad is locked well by once again

turning the pad in the left and right direction

while still depressing the lock button (E).

If the pad is locked well it should not be possible

to turn the pad.

Then unscrew pads in normal direction for right

handed thread.

P

Loading ...

Loading ...

Loading ...