Loading ...

Loading ...

Motor is supplied with a copper ground wire.

Splice this ground wire to a copper conductor

that matches motor wire size specified in

Table III. See Page 5 for wire splicing

instructions.

Permanently ground pump, motor and control

box before connecting power cable to power

supply. Connect ground wire to approved

ground first and then connect to equipment

being installed.

Do not ground to a gas supply line.

Fire and electrical shock hazard.

If using a drop wire larger than No. 10

(5.5mm

2

) (for example, No. 8 (8.4mm

2

)

wire) between pump and control box, run

wire to a separate junction box. Connect

junction box to control box with a No. 10

(5.5mm

2

) or smaller wire (depending on amp

rating of pump – see Table III).

For more information, contact your local code

officials.

WIRING CONNECTIONS:

All wiring must meet National Electrical Code or

Canadian Electrical Code and local code

requirements.

Use only copper wire when making connections

to pump and control box.

To avoid over-heating wire and excessive voltage

drop at motor, be sure that wire size is at least

as large as size listed in Table III for your

horsepower pump and length of wire run.

NOTICE: When built-in overheating protection is

not provided, use with an approved overload

equipped motor control that matches motor

input in full load amps. Select or adjust over-

load element(s) in accordance with control

instructions. When built-in overheating pro-

tection is provided, use with an approved

motor control that matches motor input in full

load amperes.

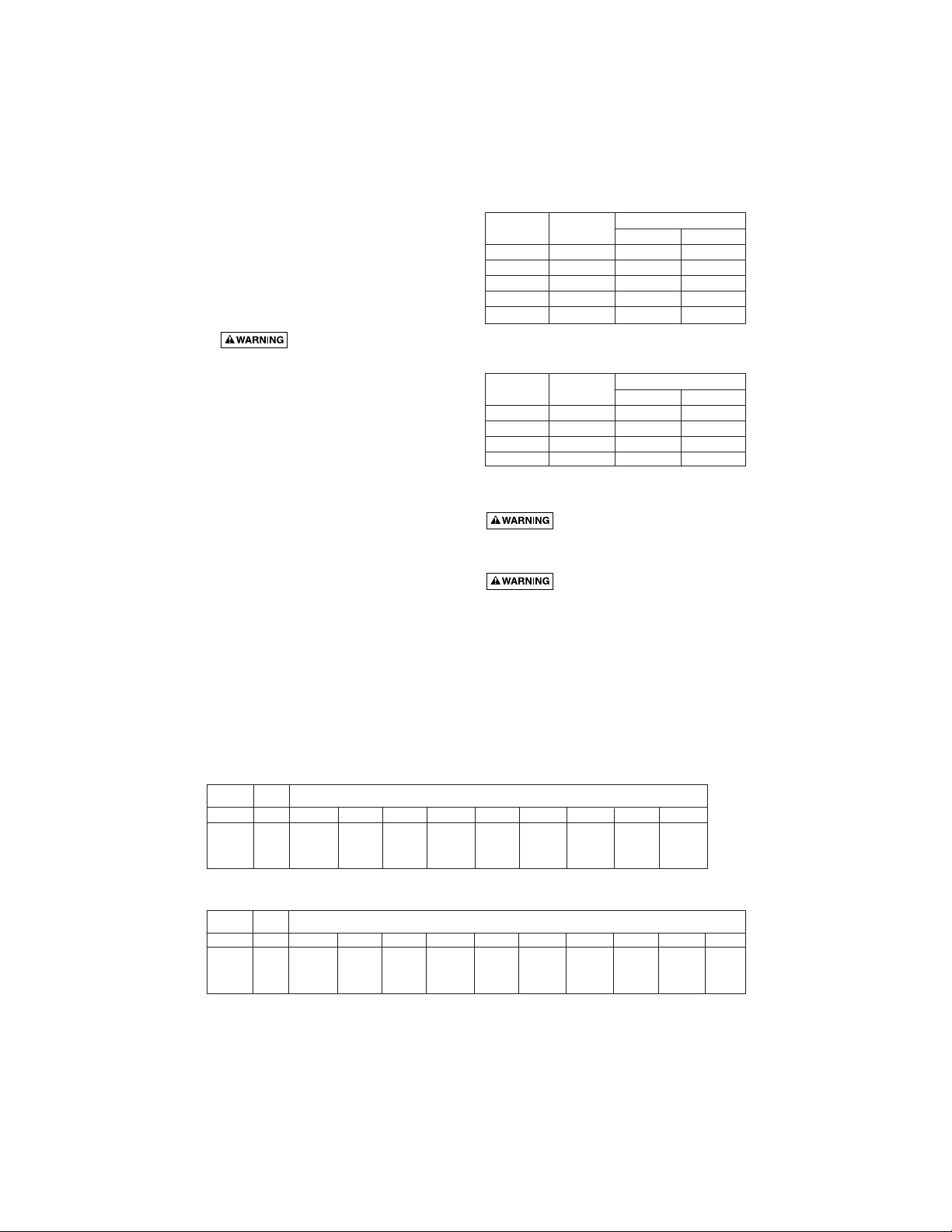

TABLE I: Recommended Fusing Data - 60 Hz.,

Single Phase, 3 Wire Submersible Pump Motors

TABLE II:

Recommended Fusing Data - 60 Hz.,

Single Phase 2 Wire Submersible Pump Motors

INSTALLATION WIRING DIAGRAMS -

SINGLE PHASE, 3 WIRE

For motors of 1

1

⁄2 HP and above, use

magnetic starter to avoid damage to pressure

switch. Consult factory for wiring information.

See Page 4 for 2 Wire Hookup.

Hazardous voltage. Can shock,

burn, or kill.

Ground control box, all metal plumbing, and motor

frame with copper wire in compliance with local

codes. Use a ground wire at least as large as the

wires supplying power to motor.

Permanently close all unused openings in this and

other equipment.

Disconnect power to control box before working on

or around control box, pipes, cable, pump, or

motor.

3

Fuse Size

HP Volts Stand Dual Elem.

1/2 115 35 20

1/2 230 20 10

3/4 230 25 15

1 230 30 20

1.5 230 35 20

Fuse Size

HP Volts Stand Dual Elem.

1/2 115 35 20

1/2 230 20 10

3/4 230 25 15

1 230 30 20

Volts HP KW 2.5 4 6 10 16 25 35 50 70

115V 1/2 .37 30m 49m 76m 119m 189m 292m 362m 445m 542m

1/2 .37 126 200 319 507 806 1282 1617 2038 2571

230V

3/4 .55 93 149 237 377 599 953 1202 1515 1911

1 .75 78 124 197 313 498 792 999 1260 1589

1-1/2 1.1 54 86 138 219 349 555 700 883 1115

1 Phase, 3- or 2- Wire Cable, 60 Hz. Wire Size in mm

2

All cable lengths meet NEC for jacketed 60°C copper cable. Based on 3-Wire Induction Run requirements; Capacitor Run requirements may vary. Local

code requirements may vary. For aluminum cable, go up two sizes from chart (for example, if the chart calls for No. 10 AWG (6mm

2

) for copper, go to

No. 8 AWG (10mm

2

) for aluminum; the smaller the number, the larger the cable). Use oxidation inhibitors on the connections.

Volts HP 14AWG 12AWG 10AWG 8AWG 6AWG 4AWG 3AWG 2AWG 1AWG

115V 1/2 100' 160' 250' 390' 620' 960' 1190' 1460' 1780'

1/2 414 658 1047 1664 2646 4207 5307 6689 8438

230V

3/4 308 489 778 1237 1967 3127 3944 4971 6271

1 256 407 647 1028 1635 2600 3280 4134 5214

1-1/2 179 285 453 721 1146 1822 2298 2897 3654

1 Phase, 3- or 2-Wire Cable, 60 Hz. Wire Size

TABLE IIIB: Copper Cable Length in Meters (Service to Motor)

TABLE IIIA: Copper Cable Length in Feet (Service to Motor)

Loading ...

Loading ...

Loading ...