Loading ...

Loading ...

Loading ...

5

5

5 Transport

A lift truck is suited for transporting the unit on a level surface.

Carrying straps may be used if the heat pump needs to be trans-

ported on an uneven surface or carried up or down stairs. These

straps can be passed directly underneath the wooden pallet.

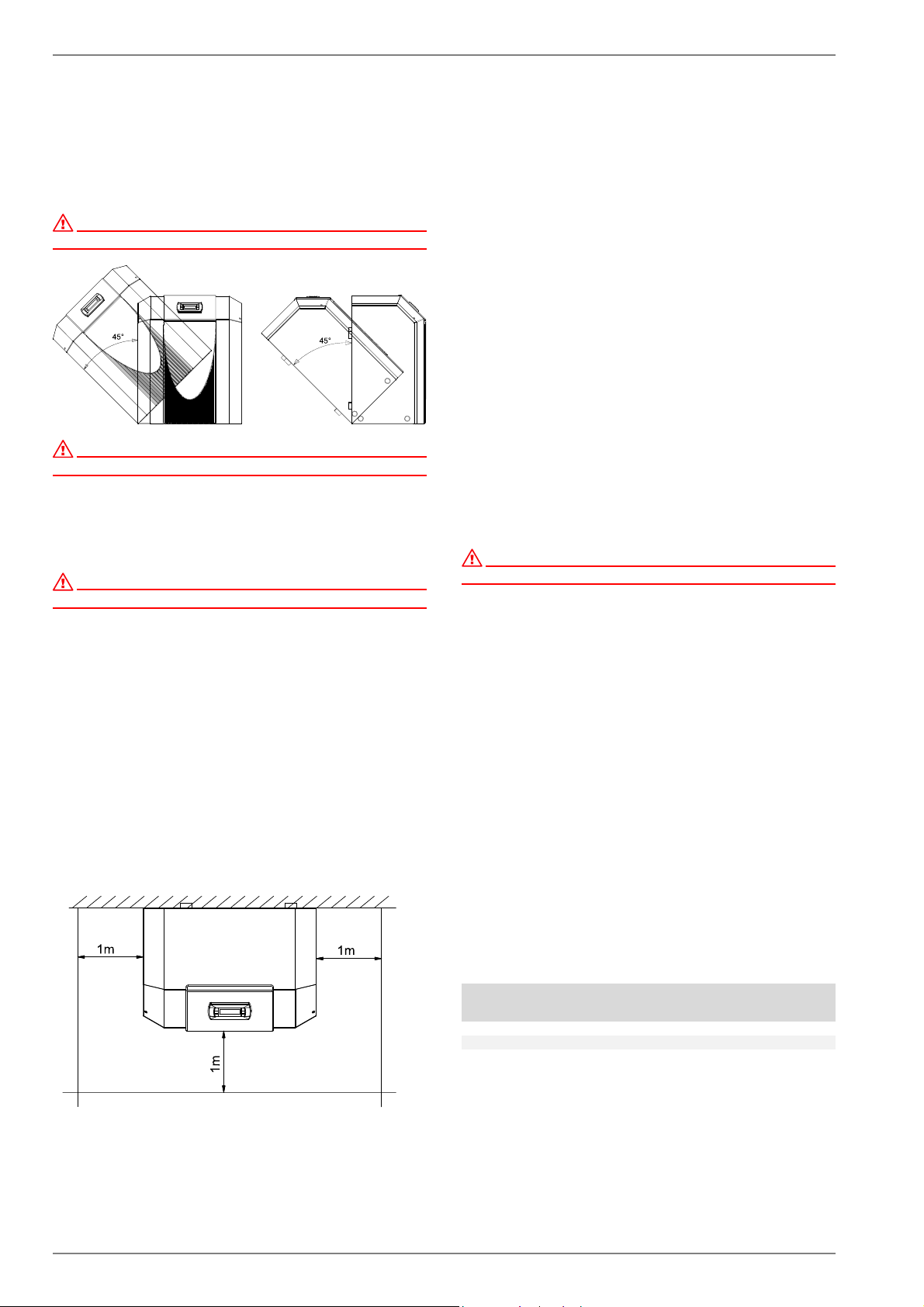

ATTENTION!

The heat pump is not secured to the wooden pallet.

ATTENTION!

The heat pump must not be tilted more than 45° (in any direction).

Use the holes provided in the sides of the frame to lift the unit

without the pallet. The side panel assemblies must be removed

for this purpose. Any commercially available length of pipe can

be used as a carrying aid.

ATTENTION!

Do not use the holes in the panel assemblies for lifting the device!

6Set-up

6.1 General Information

The unit may only be installed indoors in rooms with low humidity

on a level, smooth and horizontal surface. The entire base of the

frame should lie directly on the floor to ensure a good soundproof

seal. If this is not the case, additional sound insulation measures

may be necessary.

The heat pump must be installed so that maintenance work can

be carried out without hindrance. This can be ensured by main-

taining a clearance of approx. 1 m in front of and on each side of

the heat pump.

Neither frost nor temperatures higher than 35°C must occur in

the installation location at any time of the year.

6.2 Acoustic Emissions

The heat pump operates silently due to efficient sound insulation.

To prevent noise transmission to the foundation, a suitable,

sound dampening rubber mat should be placed underneath the

base frame of the heat pump.

To prevent any sound from being transmitted to the heating sys-

tem, we recommend connecting the heat pump to the heating

system by means of hose sections.

7 Installation

7.1 General Information

The following connections need to be established on the heat

pump:

Flow and return flow of the brine system

Flow and return flow of the heating system

Temperature sensor

Power supply

7.2 Heating System Connection

ATTENTION!

Flush the heating system prior to connecting the heat pump.

Before connecting the heating water system to the heat pump,

the heating system must be flushed to remove any impurities,

residue from sealants, etc. Any accumulation of deposits in the

liquifier could cause the heat pump to completely break down.

Once the heating system has been installed, it must be filled, de-

aerated and pressure-tested.

Consideration must be given to the following when filling the sys-

tem:

Untreated filling water and make-up water must be of drink-

ing water quality (colourless, clear, free from sediments)

Filling water and make-up water must be pre-filtered (pore

size max. 5µm).

Scale formation in hot water heating systems cannot be com-

pletely avoided, but in systems with flow temperatures below

60°C the problem can be disregarded.

With medium and high-temperature heat pumps, temperatures

above 60°C can be reached.

The following standard values should therefore be adhered to

concerning the filling water and make-up water (according to VDI

2035 Sheet 1):

The sensors which are delivered already connected and loosely

placed in the switch box must be mounted and insulated accord-

ing to the block diagram.

Total heat

output in [kW]

Total alkaline earths

in mol/m³ and/or

mmol/l

Total

hardness in dH

up to 200

2.0 11.2

200 to 600

1.5 8.4

> 600 < 0.02 < 0.11

Loading ...

Loading ...

Loading ...