Loading ...

Loading ...

Loading ...

Page 33

Installation and Operation Manual - Cape Town 1800

ENGLISH

8.2.1 R Factor

There are two ways to calculate the R-value of the floor protection. First, by adding the R-values of

materials used, or by the conversion if the K factor and thickness of the floor protection are given.

To calculate the total R value from R values of the materials used, simply add the R-values of materials.

If the result is equal to or greater than the R-value requirements, the combination is acceptable.

R-values of some selected materials are shown below :

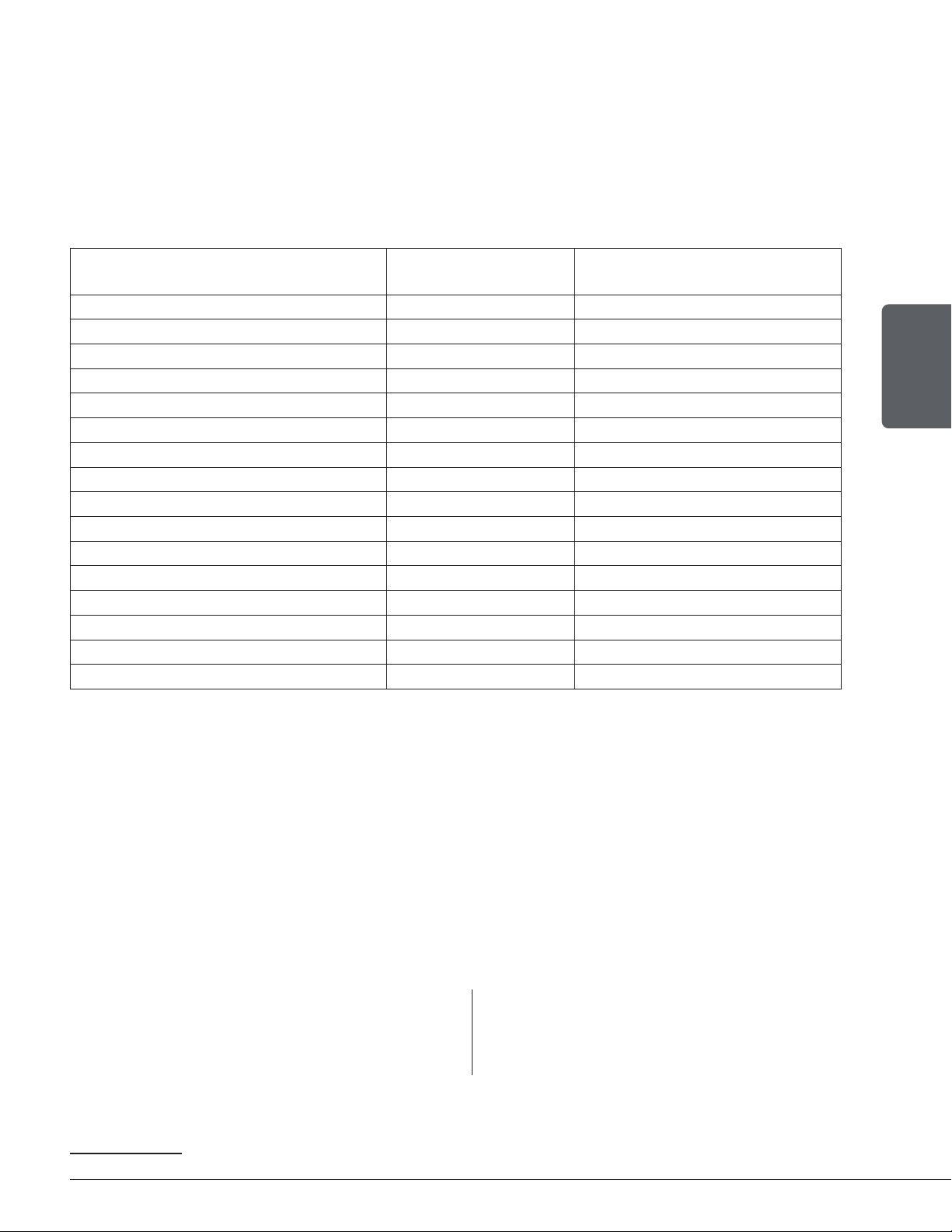

Table 2 : Thermal Characteristics of Common Floor Protection Materials

22

MATERIAL

CONDUCTIVITY (K)

PER INCH

RESISTANCE (R) PER INCH

THICKNESS

Micore® 160 0.39 2.54

Micore® 300 0.49 2.06

Durock® 1.92 0.52

Promafour

Hardibacker® 1.95 0.51

Hardibacker® 500 2.3 0.44

Wonderboard® 3.23 0.31

Cement mortar 5.00 0.2

Common brick 5.00 0.2

Face brick 9.00 0.11

Marble 14.3 – 20.00 0.07 – 0.05

Ceramic tile 12.5 0.008

Concrete 1.050 0.950

Mineral wool insulation 0.320 3.120

Limestone 6.5 0.153

Ceramic board (Fibremax) 0.450 2.2

Example:

Required floor protection R of 1.00. Proposed materials: four inches of brick and one inch of

Durock® board.

Four inches of brick (R = 4 x 0,2 = 0,8) plus 1 inch of Durock® (R = 1 x 0.52 = 0.52).

0.8 + 0.52 = 1.32.

This R value is larger than the required 1.00 and is therefore acceptable.

In the case of a known K and thickness of alternative materials to be used in combination,

convert all K values to R by dividing the thickness of each material by its K value. Add R values

of the proposed materials as shown in the previous example.

Common brick K value = 5

Thickness = 4"

R value = Thickness/K = 4/5 = 0.8

Durock K value =1.92

Thickness = 1"

R value = Thickness/K = 1/1.92 = 0.52

Total R value = .8 + 0.52 = 1.32

22

Information as reported by manufacturers and other resources

Loading ...

Loading ...

Loading ...