Loading ...

Loading ...

Loading ...

13

GB

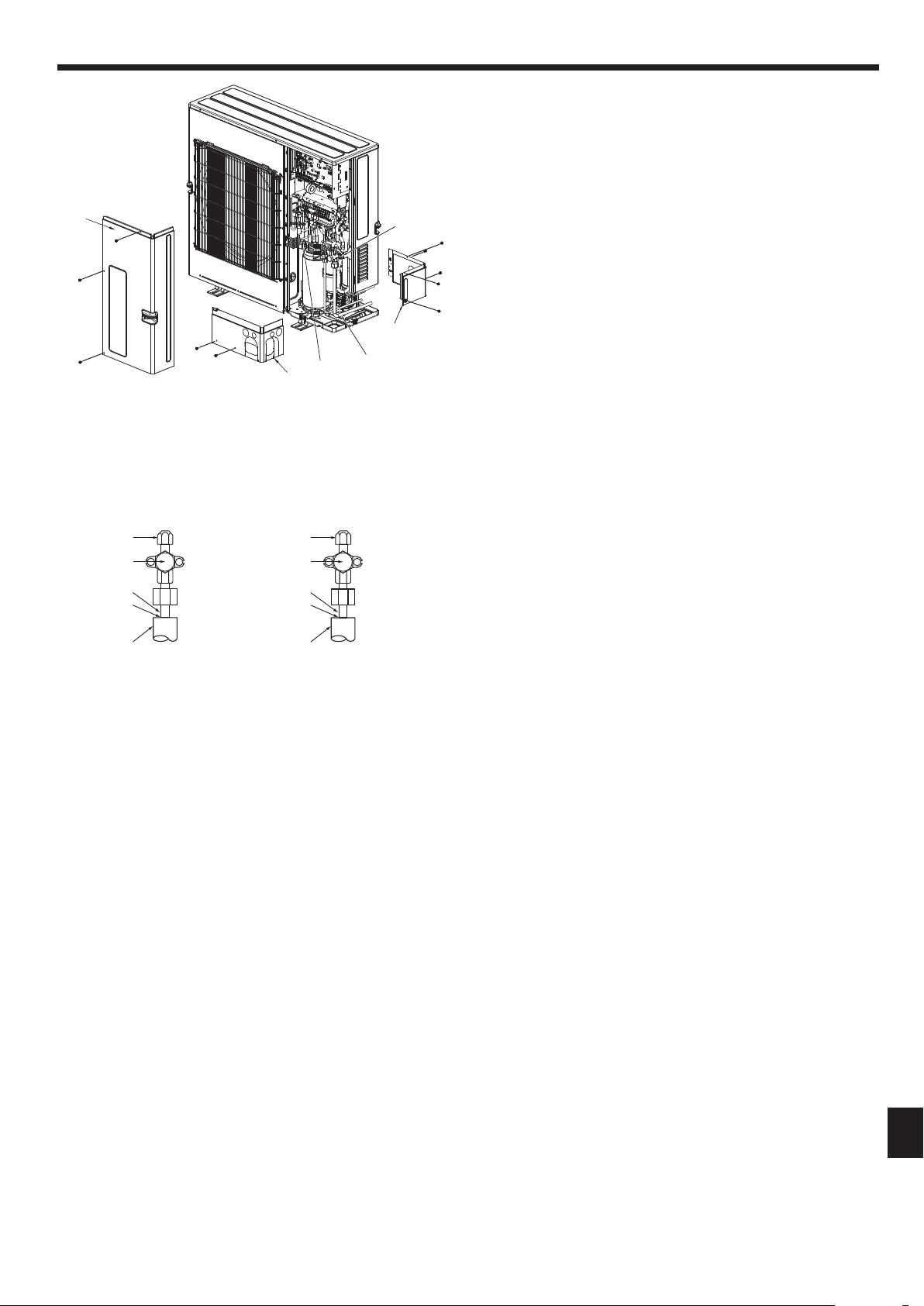

4.3. Refrigerantpiping(Fig.4-10)

Remove the service panel D (three screws) and the front piping cover A (two screws)

and rear piping cover B(vescrews).

1 Performrefrigerantpipingconnectionsfortheindoor/outdoorunitwhentheoutdoor

unit’s stop valve is completely closed.

2 Vacuum-purge air from the indoor unit and the connection piping.

3 After connecting the refrigerant pipes, check the connected pipes and the indoor

unit for gas leaks. (Refer to 4.4. Refrigerant pipe airtight testing method)

4 Vacuumize the refrigerant lines through the service port of the liquid and gas stop

valves. And then open the stop valves completely (for both the liquid and gas stop

valves). This will completely connect the refrigerant lines of the indoor and outdoor

units.

• Ifthestopvalvesareleftclosedandtheunitisoperated,thecompressorand

control valves will be damaged.

• Usealeakdetectororsoapywatertocheckforgasleaksatthepipeconnec-

tion sections of the outdoor unit.

• Donotusetherefrigerantfromtheunittopurgeairfromtherefrigerantlines.

• Afterthevalveworkiscompleted,tightenthevalvecapstothecorrecttorque:

20to25N·m(200to250kgf·cm).

Failure to replace and tighten the caps may result in refrigerant leakage. In

addition, do not damage the insides of the valve caps as they act as a seal to

prevent refrigerant leakage.

5Usesealanttosealtheendsofthethermalinsulationaroundthepipeconnection

sections to prevent water from entering the thermal insulation.

4.4. Refrigerantpipeairtighttestingmethod

(1) Connect the testing tools.

• MakesurethestopvalvesA B are closed and do not open them.

• AddpressuretotherefrigerantlinesthroughtheserviceportC of the liquid

stop valve A and the gas stop valve B.

(2)Donotaddpressuretothespeciedpressureallatonce;addpressurelittlebylittle.

1 Pressurize to 0.5 MPa (5kgf/cm

2

G),waitveminutes, and make sure the

pressure does not decrease.

2 Pressurizeto1.5MPa(15kgf/cm

2

G),waitveminutes,andmakesurethe

pressure does not decrease.

3 Pressurizeto4.15MPa(41.5kgf/cm

2

G) and measure the surrounding tem-

perature and refrigerant pressure.

(3)Ifthespeciedpressureholdsforaboutonedayanddoesnotdecrease,thepipes

have passed the test and there are no leaks.

• Ifthesurroundingtemperaturechangesby1°C,thepressurewillchangeby

about0.01MPa(0.1kgf/cm

2

G). Make the necessary corrections.

(4) If the pressure decreases in steps (2) or (3), there is a gas leak. Look for the source

of the gas leak.

Fig.4-10

A Front piping cover

B Piping cover

C Stop valve

4. Installingtherefrigerantpiping

Fig.4-11

A Stopvalve<Liquidside>

B Stopvalve<Gasside>

C Service port

D Open/Closesection

E Local pipe

F Sealed, same way for gas side

G Pipe cover

A B

C

D

E

F

G

D

E

F

G

C

D Service panel

E Bend radius : 100 mm - 150 mm

F Strap

D

A

B

C

E

F

RG79Y960H01.indb 13 2018/02/09 14:31:08

Loading ...

Loading ...

Loading ...