Loading ...

Loading ...

Loading ...

Page 8 of 16 Zip HydroTap Installation and Operating Instructions - 89585 - March 2016 v2.03

Installation Procedure continued

Step B - Installing the undersink unit

SPECIAL NOTE: The HydroTap undersink units are heavy, take note of the

weights listed in the table on page 6. If you think you cannot lift the unit

safely, get help and avoid possible injury.

Position the Zip HydroTap undersink unit as close as possible to directly beneath the

Zip HydroTap tap head.

The connection tubes supplied with the tap head assembly CANNOT be lengthened.

Allow at least a 65 mm air-gap to the LHS for air circulation

Note:

Included in the installation pack are adhesive backed silicon buffers. If air vents are

not installed in the cupboards housing the HydroTap, the buffers must be placed on

the inside edge of the cupboard door to create a slight gap ensuring a minimum

airflow. Failure to do this may cause the HydroTap to overheat and operate

inefficiently.

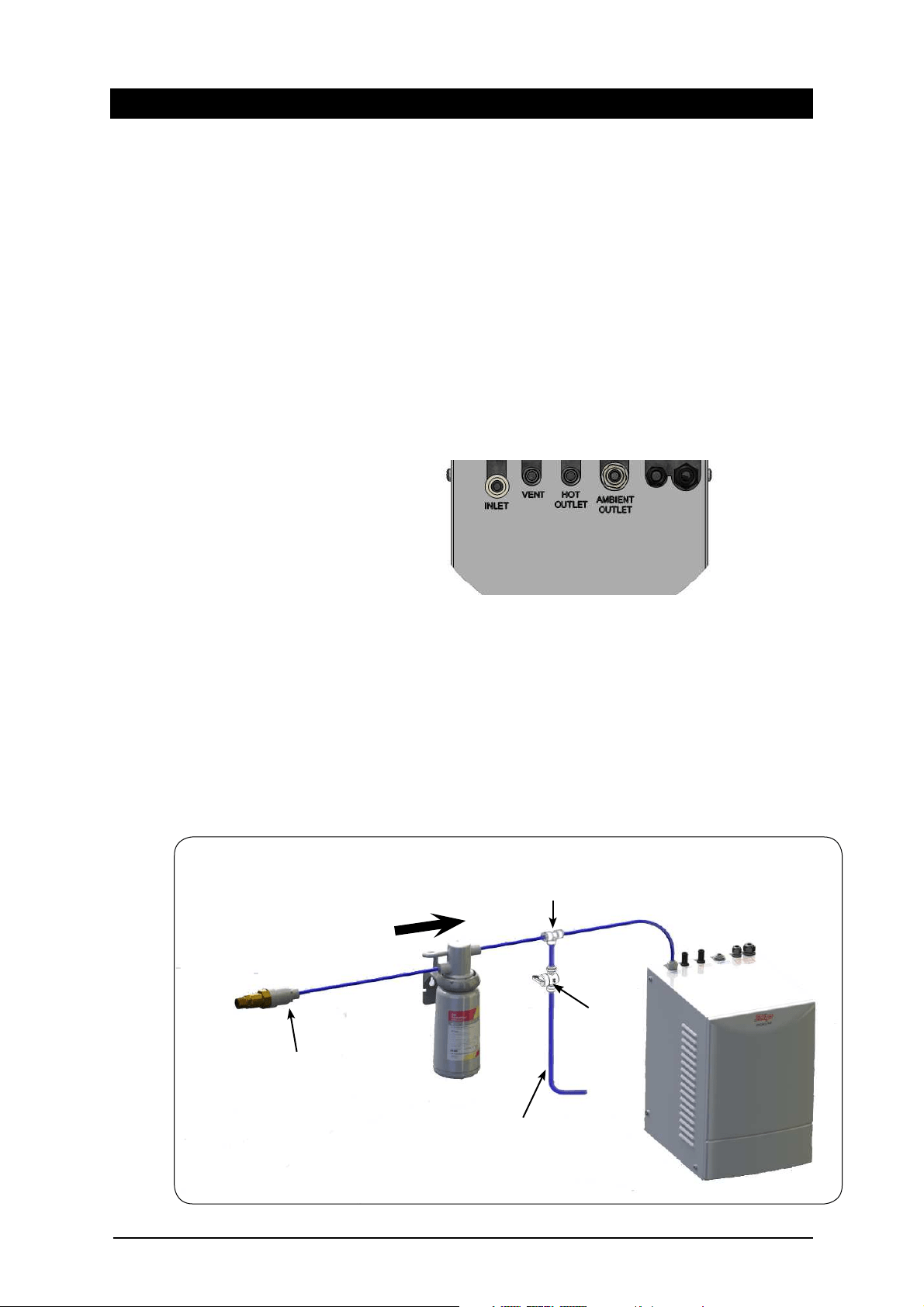

Step C - Installing the filter

The Miniboil is supplied with an external filter (see diagram below). It is important

the filter be securely fixed adjacent to the under sink unit in such a manner as to

allow for easy access to the filter, for service and regular replacement.

The ¼” tube supplied must be carefully measured and cut to allow for the

connection of the filter, double check valve and JG fittings.

Filter assembly sequence: (see fig.1)

This instruction is critical :

Adjust both cupboard door hinges and

attach the supplied rubber door buffers to

the doors to create a 4 mm air-gap

between the doors and the cupboard. This

is the minimum ventilation requirement

for low usage installations.

Proper air circulation is important for

efficient running of the Hydrotap models.

Therefore cupboard ventilation for

Hydrotap models is recommended.

Connection as viewed from the top

Flow Direction

Pressure Limiting Valve

External Filter Connection Fig. 1

Flush Tube

Tee Piece

Flush Valve

Loading ...

Loading ...

Loading ...