Loading ...

Loading ...

Loading ...

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

—

40

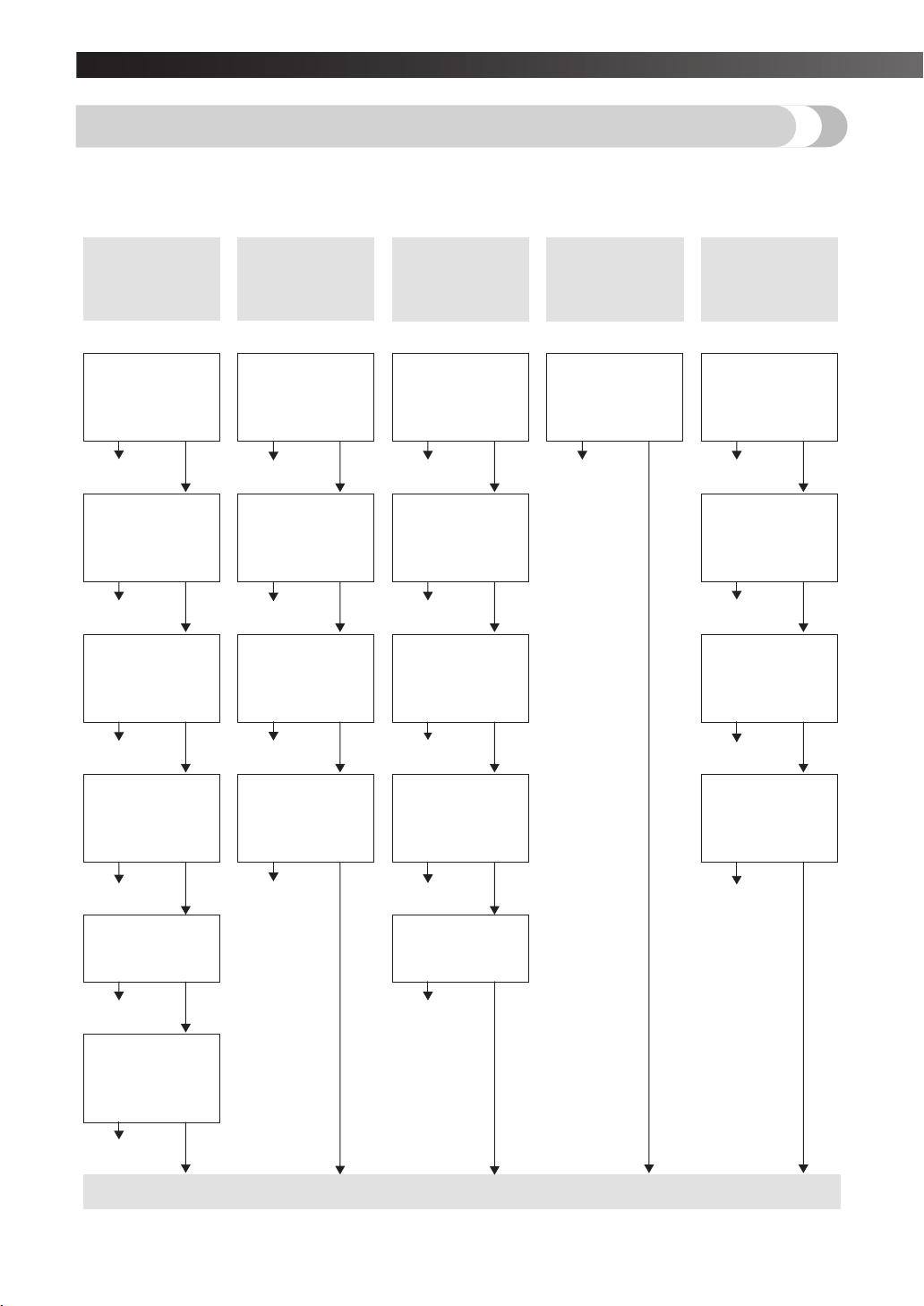

Performance Checklist

Whenever sewing difficulties are encountered, first review the manual section about the operation that you are

performing, to make sure you are using the machine correctly. If the problem persists, the following checklist

may help improve the operation.

If you still have difficulties, contact your nearest service center.

The combination

of needle size/

thread size/fabric

is incorrect.

No No No No No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

FABRIC

PUCKERS

SKIPPED

STITCHES

LOOP IN SEAM

LOWER THREAD

BREAKS

UPPER THREAD

BREAKS

Lower thread is

tangled.

Needle is incor-

rectly inserted.

Thread tension is

incorrect.

Thread tension is

too tight.

Bobbin is not

threaded properly

in the shuttle

hook.

Upper thread is

tangled.

Inferior needle is

used.

Threading is not

correct.

The combination

of needle size/

thread size/fabric

is incorrect.

Lower thread

tension is too

tight.

Upper thread

tension is too

tight.

Wrong needle is

used.

Spool of thread is

not correctly

installed.

Lint is clinging to

the bottom of the

needle plate.

Lower threading is

not correct.

Needle is bent or

not sharp.

Threading is not

correct.

The combination

of needle size/

thread size/fabric

is incorrect.

CONTACT YOUR LOCAL SERVICE CENTER

Upper threading

is not correct.

Page 18 Page 16 Page 8 Page 22 Page 22

Page 18 Page 16 Page 8 Page 16-18

Page 22 Page 22 Page 24 Page 8

Page 18 Page 16 Page 39 Page 24

Page 8 Page 16-18

Page 24

XL5000us.book Page 40 Tuesday, October 28, 2003 11:01 AM

Loading ...

Loading ...

Loading ...