Loading ...

Loading ...

Loading ...

11

Installation Specifications

Calculating Maximum Duct Run Length

• For best performance, consult a qualified HVAC specialist

when designing the duct system.

• Do not use duct work that is smaller than the required

sizes in the tables below.

• For best performance, keep the duct run as short as pos-

sible, and never exceed the maximums in the table in the

Duct Work Design Tips section.

• The max. duct length for the downdraft vent depends on

the blower used, and number of elbows and transitions.

The Equivalent Number of Feet for each elbow and

transition must be subtracted from the maximum straight

length to compensate for wind resistance. To decide the

maximum allowable length of the ducting, subtract all

equivalent lengths of the elbows and transitions listed

below from the Blower Maximum Duct Straight Length.

Example: For a downdraft vent system using a 3¼ x 10

rectangular duct, two (2) 3¼ x 10 90° elbows, a 3¼ x

10” rectangular to 10” round transition, and a REMP16

remote blower:

• From the Blower Maximum Duct Straight Length table,

the max length without transitions and elbows is 60 ft.

• The equivalent length of each 90° elbow is 15 ft.

• The equivalent length of 45° elbow is 2 ft.

• The equivalent length of the transition is 4 ft.

• The total equivalent length of the above parts is: 15 ft +

15 ft + 4 ft + 2 ft = 36 ft.

• The max amount of straight duct that can be used with a

REMP16 and the above parts is: 60 ft – 34 ft = 24 ft.

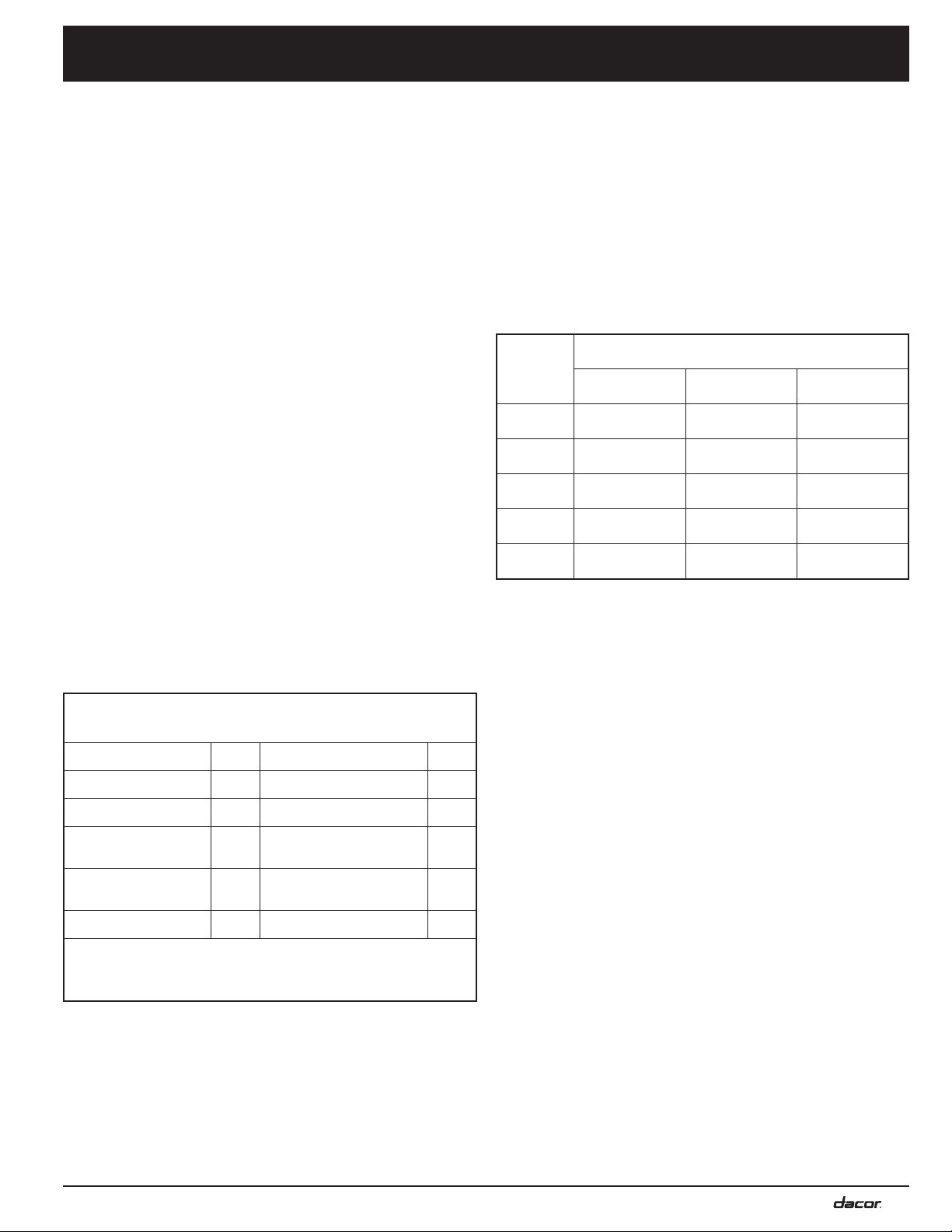

Equivalent Number of Feet (Nominal) -

Duct Elbows and Transitions

45° elbow/8” 3 ft 3¼ x 10/45° elbow 7 ft

45° elbow/10” 2 ft 3¼ x 10/90° elbow 15 ft

90° elbow/8” 7 ft 3¼ x 10/90° flat elbow 20 ft

90° elbow/10” 5 ft

3¼ x 10 to

8” round transition

4 ft

90° 3 ¼ x 10 to

8” round transition

25 ft

3¼ x 10 to

10” round transition

4 ft

Roof cap * Wall cap** *

*Equivalent lengths of roof and wall caps vary with model and

configuration. For equivalent length, contact the manufacturer or

a qualified HVAC specialist; **Not applicable to REMP blowers.

Duct Work Design Tips

• Reduce transitions and turns to the fewest sharp angles.

Two staggered 45° angles are better than one 90°. Keep

turns as far from the hood exhaust as possible, with the

most possible space between each bend.

• For best performance, use round ducting when possible,

especially when elbows are required.

• If multiple elbows are used, try to keep a minimum of 24”

of straight duct between them. Avoid “S” or “back to back”

configurations of adjacent elbows.

• Do not use flexible metal ducting.

Blower

Blower Maximum Duct Straight Length

8” Duct 10” Duct

3¼ x 10 Duct

CABP3

40 ft (12.2 m) 30 ft (9.2 m) 30 ft (9.2 m)

ILHSF8

50 ft (15.2 m) 40 ft (12.2 m) 40 ft (12.2 m)

ILHSF10

60 ft (18.3 m) 70 ft (21.3 m) 60 ft (18.3 m)

REMP3

50 ft (15.2 m) 40 ft (12.2 m) 40 ft (12.2 m)

REMP16

60 ft (18.3 m) 70 ft (21.3 m) 60 ft (18.3 m)

Loading ...

Loading ...

Loading ...