Loading ...

Loading ...

Loading ...

38

English

Installation

NOTE

• The pipe will be insulated and fixed permanently into

position after finishing the installation and the gas leak

test. For further details. see Step 3.1 Performing the gas

leak tests on page 40.

CAUTION

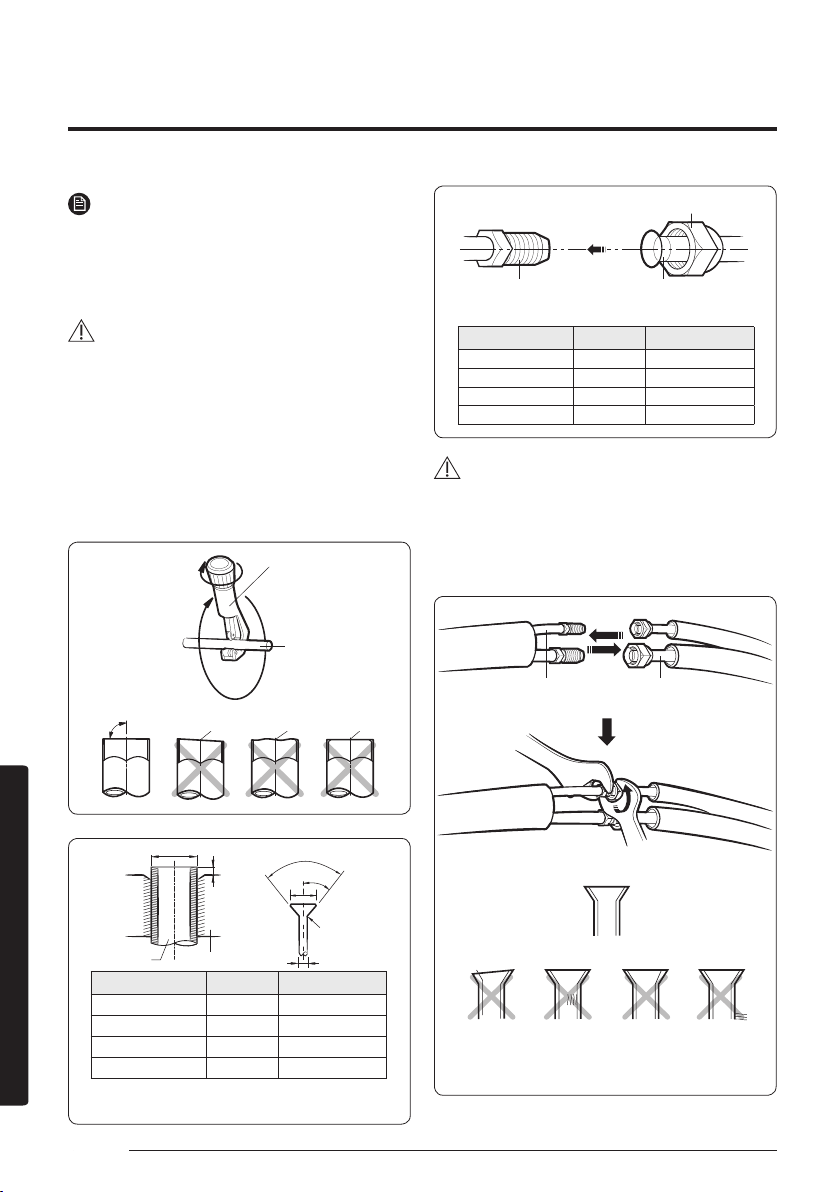

• Tighten the flare nut with a torque wrench according to

specified method. If the flare nut is over-tightened, the

flare may break and cause refrigerant gas leakage.

• Do not box in or cover the pipe connection. All refrigerant

pipe connection must be easily accessible and

serviceable.

Step 2.7 Shortening or extending the

refrigerant pipes (assembly pipe)

90°

R 0.4 to 0.8

90°±2°

45°±2°

L

D

D

A

CAUTION

• If you need a pipe longer than specified in piping codes

and standards, you must add refrigerant to the pipe.

Otherwise, the indoor unit may freeze.

• While removing burrs, put the pipe face down to make

sure that the burrs do not get in to the pipe.

Pipe cutter

Pipe

Oblique Rough

Burr

(Unit: mm)

Outer diameter (D) Depth (A) Flare dimension (L)

ø 6.35 1.3 8.7 to 9.1

ø 9.52 1.8 12.8 to 13.2

ø 12.70 2.0 16.2 to 16.6

ø 15.88 2.2 19.3 to 19.7

(Unit: mm)

Outer diameter (mm) Torque(N•m) Torque(kgf•cm)

ø 6.35 14 to 18 140 to 180

ø 9.52 34 to 42 350 to 430

ø 12.70 49 to 61 500 to 620

ø 15.88 68 to 82 690 to 830

Pipe

Flare

Connecting pipe

Indoor outlet pipe

Flare nut

<Flare nut>

Liquid service port

<High pressure>

Gas service port

<Low pressure>

Correct

Inclined Cracked

Uneven

thickness

Damaged

surface

Indoor Unit Installation

Loading ...

Loading ...

Loading ...