Loading ...

Loading ...

Loading ...

6 | JL Audio - MHD750/1 Owner’s Manual

7

Ground Connection

The ground connection should be made using

the same gauge wire as the power connection.

It is common for the alternator to be grounded

through its chassis. If the alternator is not

grounded through its chassis and instead employs

a small (10 AWG - 6 AWG) wire to connect to

ground, this wire should also be upgraded to 4

AWG when installing amplifier systems with main

fuse ratings above 60A.

Many vessels employ small (10 AWG - 6 AWG)

wire to ground the battery to the vessel chassis

and to connect the alternator’s positive

connection to the battery. To prevent voltage

drops, these wires should be upgraded to 4

AWG pure copper wire when installing amplifier

systems with main fuse ratings above 60A.

Turn-On Wire

The MHD750/1 uses a conventional +12V

remote turn-on wire, typically controlled by

the source unit’s remote turn-on output. The

amplifier will turn on when +12V is present at

its “Remote” input and turn off when +12V is

switched off. If a source unit does not have a

dedicated remote turn-on output, the amplifier’s

turn-on lead can be connected to +12V via a

switch that derives power from an ignition-

switched circuit.

The MHD750/1’s “Remote” turn-on connector

is designed to accept 18 AWG – 12 AWG wire. 18

AWG is more than adequate for this purpose.

To connect the remote turn-on wire to the

amplifier, first back out the set screw on the

bottom of the Power Connector Plug, using the

supplied 2.5 mm hex wrench. Strip 1/2 inch

(12mm) of wire and insert the bare wire into the

receptacle, seating it firmly so that no bare wire

is exposed. When using smaller wire, it may

be necessary to strip 1 inch of insulation from

the wire and fold the bare wire in half prior to

insertion. While holding the wire in the terminal,

tighten the set screw firmly using the supplied

2.5 mm hex wrench, taking care not to strip the

head of the screw and making sure that the wire

is firmly gripped by the set screw.

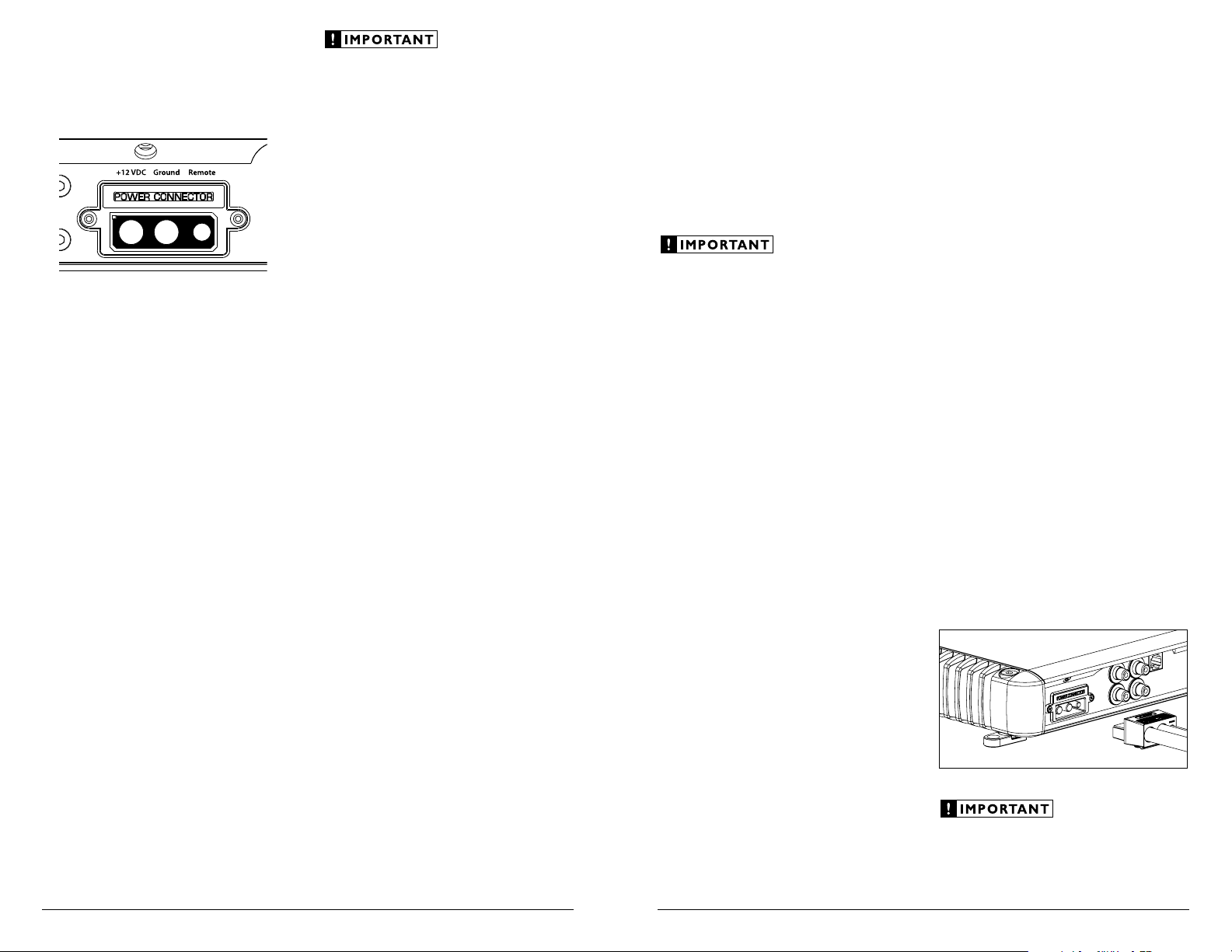

Amplifier Power Connector Plug

To connect the power wires and the remote

turn-on wire to the amplifier, unplug the power

connector plug from the amplifier chassis (pull

back firmly) and back out the set screws on

the connector plug, using the supplied 4 mm

hex wrench for the “+12 VDC” and “Ground”

connections and the supplied 2.5 mm hex wrench

for the “Remote” connection. Strip 3/8 inch (10

mm) of insulation from the end of each wire and

insert the bare wire into the receptacle on power

connector plug, seating it firmly so that no bare

wire is exposed. While holding each wire in place,

tighten each set screw firmly, taking care not to

strip the head of the screw.

Never make power connections with a “live”

wire. Always disconnect the negative battery

post before making any connections or

adjustments to a 12V power connection!

POWER AND TURNON CONNECTIONS

Before installing the amplifier, disconnect the

negative (ground) wire from the vessel’s battery.

This will prevent accidental damage to the system,

the vessel and your body during installation.

Remote

Level

Control

Inputs

L

R

L

R

+12 VDC Ground Remote

Preouts

+12 VDC Ground Remote

+12V Battery Connection

You will need to connect a power wire to

the vessel’s positive battery terminal, using an

appropriate power ring or specialized battery

terminal connector, such as the JL Audio

XB-BTU. This connection must be tight and

corrosion-free to ensure proper connectivity.

This wire MUST be fused appropriately for safety.

Any positive power wires run through barriers

must be protected with a high quality insulating

grommet to prevent damage to the insulation

of the wire. Failure to do so may result in a

dangerous short circuit.

Power Wire Requirements

The MHD750/1’s “+12 VDC” and “Ground”

connections are designed to accept 4 AWG power

wire. 4 AWG pure copper wire is recommended

for any power wire run longer than 72 inches (180

cm). For runs shorter than 72 inches, 8 AWG pure

copper power wire is acceptable.

If you are installing the MHD750/1 with other

amplifiers and wish to use a single main power

wire, use 2 AWG or 1/0 AWG pure copper wire

as a main power wire. This 2 AWG or 1/0 AWG

power wire should terminate into a distribution

block mounted as close to the amplifiers as

possible and should connect to the MHD750/1

with 4 AWG or 8 AWG pure copper power wire.

Please note that lower AWG numbers mean

bigger wire and vice-versa (1/0 AWG is the largest,

2 AWG is smaller, then 4 AWG, then 8 AWG, etc.).

We do not recommend the use of “copper-

clad aluminum wire” or “CCA” wire because

this wire is significantly less conductive than

pure copper wire. Only use pure copper power

wire, such as JL Audio’s MetaWire™. Tinned

copper wire (silver color) is acceptable as the

tin-plating is only a very minor component of

the wire.

Fuse Requirements

The installation of a fuse on each power wire,

within 18 wire inches (45 cm) of the positive

battery terminal is vital to protect the wire and

the vessel from fire in the event of a collision or

short-circuit. The fuse value at each power wire

should be high enough for all of the equipment

being run from that power wire.

If only the MHD750/1 is being run from

that power wire, we recommend a 60A fuse

be used. AGU (big glass fuse). AFS (small

blade fuse) or MaxiFuse™ (big plastic-

body fuse) types are recommended.

If other amplifiers are also being powered from

a main power wire and exceed 80 amps in total

fuse rating, we recommend the use of an ANL

(large-blade) fuse and holder. Each amplifier

must be fused independently at the outputs of

the power distribution block. Use JL Audio part

XC-FOA-2PAK and appropriate MaxiFuse™ type

fuses with JL Audio distribution blocks.

Please consult with your JL Audio

dealer to make sure that the wire, fuse

holder and fuse ratings are appropriate

for your system’s needs. The safety of

your installation depends on appropriate

power connections and fuse protection.

Loading ...

Loading ...

Loading ...